You know the feeling: you find a beautiful blouse, but it's too stiff, too sheer, or traps heat like a greenhouse. Or maybe that "breathable" shirt wrinkles the moment you put it on. With so many options, how do you choose the perfect lightweight fabric that balances drape, durability, and comfort for your collection?

The answer lies in matching fiber properties to garment intent. The "best" fabric isn't a single material—it's the right material for the specific style, season, and customer lifestyle you're designing for. It's about understanding the science behind the feel.

With over two decades in the Keqiao textile hub, I've seen fabrics evolve from basic poplins to today's high-tech blends. The key is to look beyond weight alone and consider drape, moisture management, and care requirements. Let's cut through the noise and find the ideal fabric that makes your blouses and shirts must-haves, not returns.

What are the top natural fiber choices for breathability?

When it comes to pure breathability and natural comfort, nothing beats plant-based fibers. They allow air to circulate freely and absorb moisture, keeping the wearer cool. However, not all natural fibers are created equal—each brings its own personality, advantages, and quirks to a shirt or blouse.

Choosing between them means deciding what kind of "lightweight" you want: crisp, fluid, textured, or ethereal.

Why is fine cotton still the gold standard?

For good reason. High-quality, long-staple cotton (like Egyptian or Supima) spun into fine yarns creates fabrics that are:

- Supremely Breathable & Hypoallergenic: Ideal for sensitive skin and hot climates.

- Durable & Easy to Care For: With proper weaving, it withstands frequent washing.

- Versatile in Weave: It can become airy volle, crisp poplin, soft batiste, or slightly textured oxford.

The magic is in the yarn count. For a truly lightweight yet durable shirt, look for yarns in the 80s to 100s count (Ne) or higher. A 100% long-staple cotton poplin at 100/2 yarn count feels luxuriously smooth and resists pilling. For instance, a Scandinavian minimalist brand we work with uses only GOTS-certified 120s cotton voile for their signature oversized blouses. The result is a garment that feels like air but maintains its structure through a season of wear.

How do linen, silk, and hemp compare for summer styles?

These are the icons of effortless, cool style.

- Linen: Made from flax, it's the champion of moisture-wicking and quick-drying. Its slightly coarse texture and natural slubs give a relaxed, rustic elegance. The downside? It wrinkles easily—but that's part of its charm. A linen-cotton blend (e.g., 55% linen/45% cotton) offers a perfect compromise: better drape and reduced wrinkling while retaining breathability.

- Silk: The ultimate in luxury and natural temperature regulation. It feels cool in summer and warm in winter. For blouses, charmeuse offers a glossy drape, chiffon is ethereally sheer, and habotai is a lightweight workhorse. The challenges are cost, delicacy in washing, and water spot marks. (Here's a tip from our finishers: a light sand-washed finish can give silk a more matte, durable, and less spot-prone hand).

- Hemp: A rising star. Similar to linen in its cooling properties but often even more durable and naturally resistant to mold and UV rays. It softens beautifully with each wash. For a modern take, look into blended hemp and organic cotton fabrics for eco-fashion.

Which man-made fibers offer performance and value?

Don't let old prejudices fool you. Modern regenerated and synthetic fibers have evolved into high-performance, sustainable, and incredibly versatile options for contemporary shirting. They solve specific problems that natural fibers sometimes can't, especially for travel, active lifestyles, or budget-conscious lines.

These fibers are engineered for function, offering consistency, durability, and unique aesthetics at various price points.

What makes rayon/viscose and lyocell so popular for drape?

These are regenerated cellulose fibers, made from plant pulp. They are beloved for their fluidity.

- Rayon/Viscose: Offers an unparalleled silky, fluid drape and a beautiful luster at a very accessible price point. It's great for flowing blouses and printed styles. The catch? It can be weaker when wet and may shrink if not properly finished. Always look for "stabilized" or "pre-shrunk" viscose.

- Lyocell (especially Tencel™): Think of it as rayon's more responsible, high-performance cousin. Made in a closed-loop process, it is exceptionally soft, strong (even when wet), and moisture-wicking. It has a beautiful, heavier fluidity than viscose and dyes brilliantly. It's a top choice for eco-conscious brands seeking premium drape. A German sustainable brand's best-selling shirt is made from our Tencel™ Lyocell with a micro-crease finish—it travels wrinkle-free and feels like a second skin.

Are there high-quality, lightweight polyester options?

Absolutely. The keyword is high-quality. Not all polyester is the cheap, plasticky fabric of the past.

- Microfiber Polyester: Filaments finer than silk can be woven into incredibly soft, lightweight, and durable fabrics. They excel in moisture-wicking and quick-drying.

- Polyester Crepe: Created with high-twist yarns, it has a dry, bouncy hand, beautiful drape, and excellent wrinkle resistance. It's a staple for travel shirts and blouses that need to look fresh all day.

- Recycled Polyester (rPET): Offers the same performance with a much lower environmental footprint. It's becoming a mainstream choice. When sourcing, prioritize suppliers offering GRS-certified recycled polyester fabrics for verifiable content.

The real innovation is in blending. A 70% fine cotton / 30% microfiber polyester blend gives you the natural feel of cotton with the durability, wrinkle-resistance, and ease of care of polyester—a practical hero for everyday shirting.

How do fabric weaves and finishes change the game?

The fiber is just the raw ingredient. The weave determines the fabric's structure, hand, and appearance. The finish adds the final performance or aesthetic properties. This is where a mill's expertise turns a good fiber into a great fabric. Understanding these elements lets you specify exactly what you want.

You can have the same cotton, but weave it as a crisp poplin, a breezy voile, or a textured dobby—resulting in three completely different shirts.

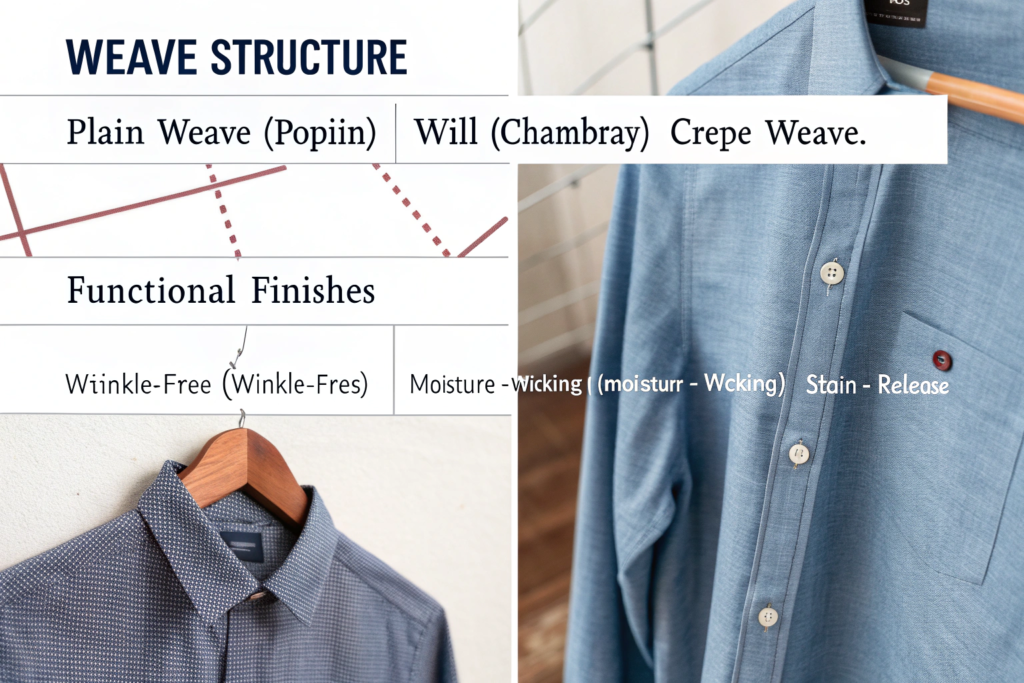

Which weaves create structure versus fluidity?

- For Crispness & Structure:

- Poplin/Plain Weave: A simple over-under weave with fine yarns. Creates a smooth, crisp, slightly lustrous surface. The classic dress shirt fabric.

- Oxford: A basket weave (often 2x1 or 2x2) using thicker yarns. More textured, durable, and casual than poplin.

- For Fluidity & Softness:

- Twill (e.g., Chambray): A diagonal rib pattern. Softer and more pliable than plain weaves, with a casual elegance.

- Crepe: Made from yarns twisted so tightly they curl, giving the fabric a pebbly texture, a dry hand, and excellent drape.

- For Sheerness & Airiness:

- Voile: A very plain, open weave using fine, high-twist yarns. Sheer, lightweight, and slightly crisp.

- Lawn: Similar to voile but with a smoother, crisper finish, often achieved through calendaring.

What functional finishes enhance lightweight fabrics?

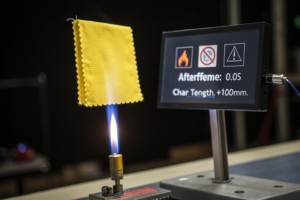

This is the secret sauce. A great finish solves a fabric's inherent weakness or boosts its strength.

- Wrinkle-Resistant (Easy Care/Non-Iron): A resin finish that cross-links cellulose fibers (cotton, linen, viscose) to help them "remember" their flat state. Crucial for travel-friendly lines. (Note: the best finishes, like ours, use green chemistry to minimize formaldehyde).

- Moisture-Wicking: A hydrophilic finish applied to natural fibers (like cotton) to help them move sweat away from the skin to the fabric's surface to evaporate. Essential for performance-influenced workwear blouses.

- Stain-Release & Soil-Repellent: Nanotechnology-based finishes that make spills bead up and allow stains to wash out more easily.

- Sand-Washing/Sueding: A mechanical process that brushes the fabric surface to create an incredibly soft, peach-fuzz hand and a muted, lived-in appearance.

Last year, we developed a linen-viscose blend with a proprietary enzyme wash for a French brand. The finish simultaneously pre-shrunk the viscose, softened the linen's harshness, and gave the entire fabric a beautifully consistent, vintage-soft hand that customers loved.

What should you consider for sourcing and production?

Choosing the perfect fabric is only half the battle. You must also ensure it can be sourced reliably, cut and sewn efficiently, and will perform in the hands of your customer. Overlooking these practicalities can turn a dream fabric into a production nightmare.

This stage is about moving from a beautiful swatch to a successful, scalable product. It involves asking the right questions before you commit to bulk.

How do you balance cost, MOQ, and lead time?

Lightweight fabrics, especially delicate ones, have specific sourcing challenges:

- Cost: Fine-count cottons, silks, and Tencel™ command a premium. Blends (e.g., cotton-poly) often offer the best balance of performance and cost.

- MOQ (Minimum Order Quantity): For custom-developed fabrics (e.g., a specific printed voile or a unique blend), MOQs can be 2,000-5,000 meters. For stock fabrics from a mill's collection, MOQs can be as low as 300-500 meters. Always ask for stock options first.

- Lead Time: Woven fabrics require more lead time than knits. For a new development, budget 8-12 weeks from order to delivery. For stock fabrics, 4-6 weeks is typical.

A clear strategy is to use a stock base fabric (like a white 80s cotton poplin) and then apply your custom printing or dyeing. This drastically reduces MOQ and lead time compared to developing a brand-new weave.

What are the key quality checks before bulk ordering?

Never skip these steps. Order a production sample (3-5 meters) from the exact bulk dye lot and run these tests:

- Wash and Dimensional Stability Test (AATCC 135): Does it shrink more than 3-5%? This is critical for pattern making.

- Colorfastness to Washing (AATCC 61) & Crocking/Rubbing (AATCC 8): Will the color run or transfer?

- Tear & Tensile Strength: Especially important for very lightweight or delicate fabrics like voile or chiffon.

- Seam Slippage Test: Do the yarns pull away at the seams under stress? A fatal flaw for garments.

We provide all this data from our CNAS lab for every bulk order at Shanghai Fumao. For a recent client's silk-blend chiffon, our report showed a 2% shrinkage and excellent colorfastness, but we flagged a moderate seam slippage risk. We advised them to adjust their seam allowance and stitch density, preventing a potential quality disaster.

Conclusion

Selecting the best lightweight fabric for blouses and shirts is a nuanced decision that blends artistry with science. It starts with choosing the right fiber for the desired breathability, drape, and feel—from the timeless cool of fine cotton and linen to the fluid performance of lyocell and high-tech polyesters. The fabric's character is then defined by its weave and enhanced by functional finishes that add wrinkle resistance, moisture management, or a luxurious hand. Finally, practical considerations of cost, MOQ, and rigorous pre-production testing ensure your beautiful choice becomes a viable, high-quality product.

The most successful brands don't just buy fabric; they develop partnerships with mills that understand this holistic process. They leverage their supplier's expertise to navigate these choices, from fiber selection to finishing, ensuring the final material not only looks beautiful on the mood board but also performs flawlessly in production and in the customer's wardrobe.

Ready to source the perfect lightweight fabrics that will define your next collection? At Shanghai Fumao, we specialize in the full spectrum of shirting fabrics—from GOTS-certified organic cottons and innovative Tencel™ blends to performance-ready micro-polyesters. Our team provides end-to-end support, from material selection and sampling to comprehensive lab testing and flexible sourcing solutions. Let's create shirts and blouses your customers will love to wear. Contact our Business Director, Elaine, to begin: elaine@fumaoclothing.com.