Sourcing fabric for accessories isn't like buying for apparel. A bag faces daily abrasion, a scarf needs drape and softness, and a hat requires structure and shape retention. Get it wrong, and you end up with saggy bags, scratchy scarves, or misshapen hats. What should you prioritize to find the perfect material for your accessory line?

The key is matching fabric properties to product function, not just aesthetics. You need to think about durability, weight, texture, and performance from the very first sample. This guide breaks down the specific fabric requirements for each accessory category and how to navigate the sourcing process from a supplier’s perspective.

Having worked with hundreds of accessory brands from New York to Milan, I’ve seen the common pitfalls. Success comes from asking the right technical questions upfront and partnering with a mill that understands the end-use. Let’s dive into how to systematically source fabrics that make your accessories both beautiful and functional.

What are the essential fabric properties for different accessories?

Forget one-size-fits-all. Each accessory category demands a unique set of fabric properties. The core mistake is choosing a fabric for its print or color alone, without considering how it will perform in the final product. You must prioritize technical specs over initial visual appeal.

The right properties ensure longevity, customer satisfaction, and brand reputation. Let’s break down the non-negotiable characteristics for bags, hats, and scarves.

How to choose fabric for durable bags and backpacks?

Bags are workhorses. They need to resist tearing, abrasion, and constant handling. The primary properties to source for are:

- Abrasion Resistance: Measured by Martindale or Wyzenbeek tests. For daily-use bags, look for results above 30,000 cycles.

- Tensile and Tear Strength: The fabric shouldn’t stretch too much under weight or tear easily at stress points like strap attachments.

- Dimensional Stability: It must not warp or shrink significantly, especially if it has a coating or laminate.

Popular choices include heavy-duty canvas fabrics for bag manufacturing, coated nylons (like Cordura®), and technical polyester blends. For a luxury feel, full-grain leather or high-quality PU leather are go-tos. In 2023, a Los Angeles-based backpack brand came to us with a problem: their recycled polyester fabric was pilling and tearing at the seams after a few months. We analyzed the issue and switched them to a 600D recycled nylon with a double-woven structure and a polyurethane coating. The tear strength increased by 60%, and their product return rate dropped from 5% to under 1% within a quarter.

What makes a fabric ideal for structured hats and soft scarves?

These two categories are opposites in needs.

- For Hats (like caps, fedoras, bucket hats): You need materials with good body and shape retention. The fabric must hold its form without constant re-blocking. Key properties include stiffness (hand), recovery from creasing, and often, moldability with heat (for caps). Mid-weight cotton twills, wool felts, straw fabrics (like paper straw or TOYO), and structured technical fabrics are ideal.

- For Scarves and Wraps: The priorities are drape, softness (hand feel), and warmth-to-weight ratio. Fabrics must flow gracefully. Look for fine gauges in knits or lightweight, smooth weaves. Merino wool, cashmere blends, silk (chiffon, satin), and high-grade viscose are perfect. A common pitfall is using a viscose that’s too heavy; it drapes but feels bulky. We always recommend comparing the drape coefficient of silk vs. viscose for scarves during sampling.

Where to find reliable accessory fabric suppliers?

Finding a supplier is easy. Finding a reliable one who understands accessory-specific needs is the challenge. The best sources aren’t always the biggest; they are the ones with specialized knowledge and a willingness to collaborate on smaller, custom runs typical of accessory lines.

Your sourcing channels should be a mix of broad discovery and deep verification. Trade shows and online platforms are for finding options, but the real work begins in vetting their technical capability.

Are trade shows or online platforms better for accessory fabrics?

Both have their place in a strategic sourcing plan.

- Trade Shows (e.g., Première Vision, Texworld, CIFF): Unbeatable for seeing and feeling physical quality, discovering innovations, and building face-to-face relationships. You can assess a fabric’s hand, weight, and drape instantly. It’s the best place to find niche, high-end, or innovative material suppliers. The downside is the cost and time of travel.

- Online B2B Platforms (e.g., Alibaba, specific mill websites): Excellent for efficiency, price comparison, and initial contact. They allow you to cast a wide net. However, verifying quality is harder. Always order physical swatch books or "cutting samples" before even discussing price. A key tip is to search for suppliers using specific technical terms like "suppliers of coated nylon for luggage" rather than just "bag fabric." This filters for specialists.

My advice? Use online platforms to create a longlist, then order sample swatches. Visit trade shows to deepen relationships with the 2-3 shortlisted suppliers that passed your swatch test. For instance, at the last Première Vision, I guided a Danish hat brand through the halls specifically to touch new sustainable stiffening alternatives to traditional resins—something impossible to judge online.

How to vet a supplier's technical expertise for accessories?

Once you have potential suppliers, dig deeper than MOQ and price. Ask these qualifying questions:

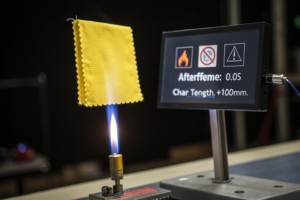

- "Can you provide a test report for abrasion resistance (Martindale) and colorfastness to rubbing (crocking) for this fabric?" A serious mill will have this data.

- "Do you have experience with the coating/laminating/finishing processes needed for this end-use?" (e.g., water-repellent coating for bags, flame lamination for cap peaks).

- "What is your process for color matching, and can you guarantee batch-to-batch consistency for small orders?"

Visit their facility if possible, or request a video tour of their lab and finishing department. Check if they have a comprehensive guide to fabric testing standards for manufacturers. At Shanghai Fumao, we once had a potential client for high-end scarf fabrics who sent us a 10-point technical checklist. We were impressed and provided all the data; they became a long-term partner because we proved our expertise upfront, not just with words but with certified lab reports.

What are the sampling and MOQ considerations?

This is where many accessory brands hit a wall. You often need small quantities of multiple specialized fabrics, but most mills are set up for large, apparel-scale rolls. Navigating sampling and MOQ discussions requires clear communication and an understanding of a mill’s production logic.

The goal is to find a supplier whose business model aligns with your scale. Some mills cater to "mini-bulk" orders, which is ideal for accessories. Be prepared for sampling to be an investment, not just a cost.

What is a realistic sampling process and cost?

A professional sampling process has stages and costs money. Expect this sequence:

- Lab Dip Sampling: You approve the color match on a small fabric swatch. This usually costs $30-$80 per color.

- Handloom/Strike-Off Sampling: You see the full pattern/weave in your chosen color on a small piece. This can cost $150-$400 per design.

- Production Sample (Bulk Yardage): A length of fabric from the actual production run for you to make final prototypes. This is often deducted from your final bulk order invoice.

For a complex accessory fabric—like a custom jacquard for a scarf or a coated technical fabric for a bag—the sampling cost can be $500-$1000. View this as essential R&D. In early 2024, a UK bag brand spent €850 on sampling three different weights of organic canvas with a custom wax finish. This allowed them to finalize their design with the perfect material, avoiding a €15,000 mistake on a bulk order of the wrong fabric.

How to negotiate MOQs for small-batch accessory production?

MOQs are about the mill's minimum economical run on a loom or dyeing machine. Your leverage comes from:

- Asking for Stock Fabric: Many mills have existing designs you can customize with your own color or a minor finish. MOQs can be as low as 100-300 meters.

- Consolidating Orders: Plan your seasonal collection so you can use the same base fabric (e.g., a neutral twill) for multiple bag styles or hat colors, meeting the MOQ with one order.

- Being Flexible on Color: "Stock color" options from a mill's existing dye range have much lower MOQs than custom-matched colors.

The most effective strategy is to be transparent. Say, "My first order is 500 meters for testing the market, but I have a 3-season projection of 3000 meters if the quality and partnership are right." This shows you're serious. We at Shanghai Fumao have a dedicated program for accessory brands where they can access our "small-batch fabric sourcing for emerging designers" library, with MOQs starting at 200 meters per design, specifically because we understand the market need.

How to ensure quality and compliance?

A beautiful accessory that fades, shrinks, or contains restricted chemicals will destroy your brand. Quality control (QC) and compliance are not final checks; they must be designed into the fabric specification from the start. This is your final and most critical line of defense.

You need to define clear, measurable standards and have a system to verify them. Don't assume the supplier's "standard quality" meets your needs. Spell everything out in a Tech Pack, even for fabric.

Which quality tests are mandatory for accessories?

| At a minimum, insist on test reports for the following, from an accredited lab (like SGS, ITS, or the supplier's own CNAS lab): | Test Type | Standard (Example) | Why It's Critical for Accessories |

|---|---|---|---|

| Colorfastness | AATCC 8 (Crocking/Rubbing) | Prevents color transfer from bags onto clothes or from scarves onto skin. | |

| Dimensional Stability | AATCC 135 (Washing) / ISO 5077 | Ensures the bag panel or hat brim doesn't shrink or warp after cleaning. | |

| Abrasion Resistance | ASTM D4966 (Martindale) | Directly relates to the lifespan of bags and high-friction areas on hats. | |

| Tensile/Tear Strength | ASTM D5034 / ASTM D1424 | Checks if fabric can handle the weight and stress in bags and straps. | |

| PH Value | AATCC 81 | Ensures fabric is skin-safe, especially for scarves and hat linings. |

Always specify the passing grade you require (e.g., "Colorfastness to rubbing: Grade 4 minimum, dry and wet").

How to navigate compliance (REACH, CPSIA, Prop 65)?

Compliance is about restricted substances. Key regulations include:

- EU REACH (SVHC): Limits substances like phthalates, heavy metals, and AZO dyes.

- US CPSIA: For children's accessories (e.g., small bags, hats), it limits lead and phthalates.

- California Prop 65: Requires warnings for exposure to listed chemicals.

The safest approach is to require your supplier to provide a General Certificate of Conformity (GCC) or a test report specifically for REACH SVHC. State clearly in your purchase contract that the supplier is responsible for compliance. For a line of children's backpacks we produced for a US client last year, we provided a full CPSIA and Prop 65 test package from Intertek. This documentation was as important as the fabric itself for their retail compliance. Never underestimate the importance of understanding global restricted substance lists for textiles.

Conclusion

Sourcing fabric for accessories is a specialized discipline that blends creative vision with technical rigor. It’s about defining the precise properties your product needs, finding and vetting suppliers with the right expertise, strategically navigating sampling and MOQs, and enforcing stringent quality and compliance standards. Success lies in treating fabric not just as a commodity, but as the foundational component of your product’s functionality and brand promise.

The most successful accessory brands build deep, collaborative partnerships with their fabric mills. They share their challenges, involve the supplier early in the design process, and leverage the mill’s technical know-how to solve problems. This transforms the supplier from a simple vendor into a strategic ally in product development.

Ready to source fabrics that elevate your bags, hats, or scarves from good to exceptional? At Shanghai Fumao, we specialize in the small-batch, high-quality, and technically demanding world of accessory fabrics. From durable coated nylons to luxurious silk blends, our team provides end-to-end support, from material selection and sampling to full compliance documentation. Let's discuss how we can provide the perfect material foundation for your next collection. Contact our Business Director, Elaine, to start a conversation: elaine@fumaoclothing.com.