Let’s be honest. You’ve probably sent a dozen RFQs to Chinese suppliers and gotten back a dozen different prices for what seems like the same fabric. One quote is suspiciously low, another is shockingly high, and the rest are somewhere in between. You want a fair price, but how do you even know what “fair” is? The fear of overpaying or, worse, getting stuck with subpar quality because you chased the cheapest option is real. This isn’t just about haggling; it’s about understanding the true value behind the meter.

Negotiating price with fabric manufacturers in China is a strategic process that moves beyond simple haggling. Success hinges on your understanding of cost drivers, the supplier’s production cycle, and building a partnership based on transparency and mutual benefit. The goal is not to squeeze every last cent, but to arrive at a sustainable price that ensures quality, reliability, and long-term value for your fashion brand or sourcing business.

For over 20 years at Shanghai Fumao, I’ve been on both sides of the table. I know what makes our costs tick, and I know what buyers truly need. This guide will pull back the curtain on the pricing structure in China’s textile heartland, Keqiao. I’ll share insider strategies that turn adversarial negotiations into collaborative problem-solving, helping you secure not just a good price, but a reliable partner for your .

What are the key factors that determine fabric prices in China?

You see a price on a quote, but it’s just the tip of the iceberg. Beneath the surface, a dozen factors are pushing and pulling that final number. Understanding these isn’t about getting a degree in textile engineering; it’s about asking the right questions and knowing what you’re actually paying for. When you comprehend the cost structure, your negotiations shift from “Can you lower the price?” to “How can we optimize these specific elements to achieve a better value?”

How do raw material choices and market volatility impact my quote?

The journey of cost begins with the fiber. A fabric made with long-staple Egyptian cotton will inherently cost more than one using standard Upland cotton. Similarly, premium Recycled Polyester (rPET) granules command a different price than virgin polyester, influenced by global oil prices and recycling supply chains. The key here is volatility. In early 2023, we saw cotton prices swing nearly 30% due to supply chain tensions. If you’re getting a quote, always ask: “Is this price based on today’s yarn rates, and is it subject to fluctuation?” A professional supplier like us at Shanghai Fumao will be transparent about this and may offer price-hedging strategies for large orders. For buyers looking to navigate this complexity, understanding global cotton price trends and sourcing strategies is crucial. It’s not just about the type of material, but its origin and the timing of your purchase.

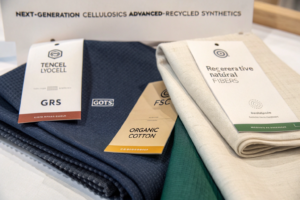

Beyond the base fiber, consider blends and specialty yarns. Adding 5% Spandex for stretch or using Tencel™ Lyocell for drape and sustainability adds cost. The rule of thumb is: the more processed the raw material, the higher the cost. A filament yarn is cheaper than a textured one; a dyed yarn is more expensive than a greige one. When negotiating, specify exactly what you need. Do you truly need that 30% silk blend, or would a high-quality Bamboo Silk (BAMSILK) alternative achieve a similar aesthetic at a better price point? We often work with clients to analyze these trade-offs.

Why do order quantity, complexity, and certifications create cost differences?

This is where economies of scale and operational overhead come into play. Let’s break it down:

| Cost Factor | Why It Affects Price | Negotiation Tip |

|---|---|---|

| Order Quantity (MOQ) | Dyeing machines and looms have setup costs. Running 1,000 meters spreads this cost thin; running 10,000 meters spreads it even thinner. | Consolidate orders or use stock fabric programs. Shanghai Fumao offers shared-dyeing batches for small designers. |

| Fabric Construction | A simple plain weave is faster and has a higher yield than a complex dobby jacquard or an elastic knitted fabric with multiple yarn feeds. | Question if a simpler construction can achieve a similar look. Sample first! |

| Finishes & Treatments | Each add-on—whether it’s a moisture-wicking finish, flame retardant coating, or embroidery—is a separate production step with its own labor and chemical costs. | Prioritize finishes. Is the water-repellency critical, or is a durable water repellent (DWR) sufficient? |

| Certifications (OEKO-TEX, GOTS) | These require auditing, segregated production lines, and certified raw materials, which add administrative and material costs. | Only pay for certifications your market demands. If selling in the EU, OEKO-TEX STANDARD 100 is often essential. |

In my experience, a European client in 2023 wanted a GOTS-certified organic cotton twill with a custom antimicrobial finish. The MOQ was challenging. By working together, we scheduled their production right after another client’s GOTS order, using the same certified dye lot, which reduced their cost by 15% because we saved on the audit and setup overhead. This is the power of collaborative negotiation.

When is the best time to negotiate for better fabric prices?

Timing in China’s manufacturing cycle isn’t just a suggestion; it’s a powerful leverage point. Factories aren’t static price-givers—their capacity, cash flow needs, and motivation change with the seasons. Aligning your negotiation and order placement with these rhythms can unlock significant advantages you won’t get by just haggling over email in a vacuum.

How can I leverage seasonal production cycles to my advantage?

China’s textile industry has predictable tides. The peak production periods are March-May (preparing for autumn/western winter) and August-October (preparing for spring/summer). During these windows, every factory is at full capacity. Your leverage is low, and prices are firm because demand outstrips supply. Asking for a 10% discount here is often a non-starter. The real opportunity lies in the slower periods: June-July and November-December. After the spring/summer rush and before the Chinese New Year (CNY) crunch, many factories have open capacity. They are more motivated to keep their machines running and workers employed. In November 2022, a US-based athleisure brand approached us with a project for recycled polyester jersey. By placing the order in mid-November for a January delivery (post-slow period), we offered a 7% better price than if they had waited until January to order for the same delivery, as we could efficiently slot it into our production schedule.

The flip side is planning around shutdowns. Chinese New Year is a 3-4 week complete stop. The month before CNY is chaotic as factories rush to complete orders. Negotiating then is futile. The smart move, like a savvy European fashion brand we work with, is to complete all pre-production 6 weeks before CNY. This allows production to start immediately when factories reopen, securing you a slot in the queue and avoiding the post-holiday premium rush. Understanding these patterns is a form of strategic negotiation.

What are the risks of ignoring factory scheduling in my planning?

If you try to force an order during peak season with a tight deadline, you face two major risks that ultimately cost more than any upfront discount:

- Quality Compromise: Rushed production leads to shortcuts. Stitch density might drop, color matching might be sloppy, or fabric inspection might be less thorough. You might save $0.10 per meter but incur massive chargebacks and returns due to quality issues. I’ve seen it happen.

- Logistics Nightmares: Missing your intended sailing schedule because of factory delays means you pay for expensive air freight. A $5,000 sea freight bill can become a $25,000 air freight bill overnight. This completely nullifies any “good price” you negotiated. A reliable partner will be honest about timelines. (Here I have to add, our lead times are genuinely fast because we control the supply chain, but even we respect the industry’s peak tides.)

The best practice is to have an open conversation: “This is my target delivery date to my warehouse. Based on your current schedule and the upcoming holidays, when do we need to finalize everything to make this happen at the best possible price?” This positions you as a professional and allows the factory to provide a realistic plan.

What negotiation strategies work beyond just asking for a lower price?

Asking “Is this your best price?” is the most common and least effective tactic. It’s a transactional approach that puts the supplier on the defensive. The most successful negotiations I’ve been part of focus on creating and claiming value collaboratively. Think of it as solving a puzzle together, where the solution benefits both sides.

How can bundling orders and long-term partnerships secure better rates?

This is the most powerful lever for serious buyers. Instead of negotiating order-by-order, discuss a quarterly or annual volume commitment. For instance, you might commit to 50,000 meters of various fabrics over the next 12 months. In return, the factory can offer:

- Tiered Pricing: Lower prices as you hit certain volume milestones.

- Priority Scheduling: Your orders jump the queue, even during peak season.

- Dedicated R&D Support: Faster and sometimes free sample development.

A practical strategy is bundling. Combine several smaller orders for different projects into one larger production run. Even if the fabrics are different, if they use the same base material (e.g., 100% cotton), the factory can consolidate the dyeing process, saving them water, energy, and time. We passed these savings directly to a Canadian retailer last year, offering a 5% discount on the entire bundled order. Explore resources on building strategic supplier relationships in Asia for more frameworks. It transforms you from a one-time customer to a valued partner.

Why is focusing on total cost, not just unit price, a smarter approach?

The cheapest fabric can become the most expensive project. You must calculate the Total Landed Cost. This includes:

- Unit Price of Fabric

- Shipping & Logistics

- Tariffs & Duties

- Cost of Quality Failures (Returns, Remakes)

- Cost of Delays (Missed Sales Seasons)

Let’s use a real case. In April 2023, a US client was deciding between two suppliers for a performance nylon fabric. Supplier A was $1.80/meter. Supplier B (us, Shanghai Fumao) was $2.00/meter.

- Supplier A had vague testing reports. We provided full CNAS-accredited lab reports (colorfastness, shrinkage, tensile strength).

- Supplier A quoted 45-day production. We confirmed 30 days due to our integrated dyeing and weaving.

- Supplier A’s port was congested. We shipped from Ningbo, a more efficient port, with our consolidated logistics.

The client chose us. Their total landed cost was actually lower because they avoided air freight, had zero quality rejects (our pass rate is 98%), and their goods arrived in time for their campaign. They paid a slightly higher unit price but saved massively on risk and hidden costs. Always negotiate with this total cost model in mind.

What are the common pitfalls to avoid during price negotiations?

Even with the best strategy, negotiations can go sideways if you fall into common traps. These pitfalls can damage the relationship before it even begins, leading to a deal where one side feels they “lost.” The goal is a win-win, not a victory that comes back to haunt you with quality issues or a supplier who disappears after one order.

How does unclear specification lead to cost overruns and conflict?

The #1 cause of post-negotiation headaches is ambiguity. If your initial request is for “black polyester,” you will get a quote for the cheapest black polyester. If you actually needed a black recycled polyester crepe with a peach-skin finish and Oeko-Tex Class II certification, you’ll be hit with change orders and price increases later, which feels like a bait-and-switch. To negotiate effectively from the start, you must provide crystal-clear specs:

- Tech Pack: Detailed construction, weight (GSM), width, composition.

- Physical Approved Sample: “Match THIS exactly.”

- Testing Standards: “Must pass AATCC 135 for shrinkage and ISO 105 for colorfastness.”

When you provide this, the factory can give you an accurate, all-inclusive price. There’s no room for “I thought that was included.” A detailed guide on creating bulletproof fabric specifications for sourcing can be invaluable. This clarity protects both parties and is the foundation of trust.

Why is choosing a supplier based solely on the lowest bid risky?

The “race to the bottom” is a dangerous game. A supplier who agrees to an unsustainably low price has only three ways to make it work:

- Use inferior materials: Blending in lower-grade yarn or using sub-standard dyes.

- Cut corners in production: Reducing quality checks, skipping processes like pre-shrinking.

- Add hidden costs later: Suddenly charging for samples, testing reports, or document fees.

I recall a client from Russia who came to us in 2022 after a bad experience. They had sourced a wool blend coating fabric from another supplier at a price 20% below market. The first shipment had inconsistent shading and pilled excessively. They lost their entire season. They paid us a fair price, and we delivered a consistent, high-quality product for three consecutive seasons. Their total profit was far higher despite the higher initial cost. Always vet your supplier. Can they provide real client references? Do they have a proper quality control system? What do their existing customers say on neutral platforms like specific industry forums for textile importers? The lowest price often carries the highest risk.

Conclusion

Negotiating fabric prices in China is not a battle to be won, but a relationship to be built. It’s a process that blends art and science—the art of communication and partnership, with the science of cost structures and production planning. By moving beyond simple price haggling to understand the factors that drive cost, strategically timing your orders, employing value-creating strategies like bundling, and avoiding the pitfalls of ambiguity and the low-bid trap, you position yourself for sustainable success.

Remember, the right partner won’t just give you a price; they’ll help you understand it. They’ll work with you to find solutions that fit your budget without compromising the integrity of your product. A true collaboration ensures that when your fabric arrives, it’s not just an item on an invoice, but the foundation of a collection you’re proud to bring to market.

If you’re ready to move from transactional quotes to a strategic partnership that delivers consistent quality, innovation, and value, let’s start a conversation. At Shanghai Fumao, we’re more than a supplier; we’re an extension of your production team. We can help you navigate the complexities of sourcing from Keqiao’s vast textile ecosystem. For a detailed discussion on how we can optimize your specific fabric needs and production schedule, please reach out to our Business Director, Elaine. She and her team are experts in translating client visions into commercially viable, high-quality fabrics. You can contact Elaine directly at elaine@fumaoclothing.com to begin co-creating the foundation of your next successful collection.