Navigating the global supply chain for custom fabrics can feel like a high-stakes puzzle for US fashion brands. You want unique prints, competitive pricing, and reliable delivery, but navigating overseas production, especially in China, often comes with hidden hurdles—unexpected delays, communication gaps, and quality inconsistencies. The promise of customization can quickly turn into a logistical headache, leaving you wondering if the cost savings are worth the operational stress.

The key to efficient sourcing lies not in avoiding Chinese manufacturing but in mastering its rhythms and partnering with the right, integrated supplier. By understanding production cycles, planning around cultural holidays, leveraging digital tools for precision, and choosing a partner with true end-to-end control, US brands can unlock China's unparalleled capabilities in custom printed fabrics without the traditional pitfalls. It's about strategic synchronization, not just finding a factory.

Let's break down the actionable strategies that transform sourcing from a chaotic scramble into a streamlined, predictable, and highly efficient component of your business growth. We'll move from the big-picture calendar planning to the nitty-gritty of digital proofing and quality assurance.

What Are the Key Timeline Factors for Sourcing from China?

You wouldn't start a road trip without checking the weather and traffic, right? Sourcing from China requires the same foresight. The single biggest mistake brands make is assuming production timelines are constant. They're not—they're deeply seasonal. Ignoring this is like driving into a hurricane; you will get delayed and your costs will blow up.

Understanding China's manufacturing calendar is your first and most powerful tool for efficiency. The year is punctuated by national holidays and seasonal productivity waves that directly impact capacity, lead times, and costs. Aligning your sourcing schedule with these patterns isn't just advisable; it's non-negotiable for maintaining your own product launch calendars and inventory flow. Smart planning around these periods is what separates the pros from the amateurs.

How Do Chinese Holidays Impact Production Schedules?

Let's get specific. Chinese New Year (CNY) is the granddaddy of all shutdowns. For 3-4 weeks around late January or February, the entire country practically stops. Factories close, workers travel home, and nothing moves. The rule is simple: your pre-production MUST be locked down at least 6 weeks before CNY. This means your lab dips, strike-offs, and bulk fabric approval should be on your supplier's desk by then. One of our clients, a Miami-based swimwear brand, learned this the hard way in 2022. They sent their final print approval on January 10th for a CNY starting on January 31st. The result? Their production slot vanished, and their summer collection was delayed by 8 weeks. Now, they work with us on a reverse timeline, starting their development cycle for custom digital prints in October for a March delivery.

National Day Golden Week in early October is a shorter but significant one-week halt. Planning a buffer week on either side is wise. Beyond holidays, recognize the natural ebb and flow. The peak seasons (Mar-May and Aug-Oct) are frantic. Everyone is producing, so ports are congested, and material shortages occur. During these times, adding 1-2 weeks to standard lead times is prudent. Conversely, the slower periods (Jun-Jul, Nov-Dec) can offer timeline advantages if you plan well. A savvy New York-based streetwear label we work with intentionally schedules their less time-sensitive, basics line production for June-July, securing better factory attention and sometimes even lower pricing by filling idle capacity.

What's the Real Process from Design to Shipping?

Efficiency is killed by ambiguity. You need a crystal-clear, step-by-step map. For custom printed fabrics, the journey from your sketch to your warehouse has distinct, non-negotiable phases. First, the tech pack and design handoff. The more detailed your tech pack—including Pantone colors, repeat specifications, and fabric base composition—the fewer revision rounds. We use AI-driven trend analysis to sometimes suggest adjustments for better printability, but your vision is the blueprint.

Next comes sampling and approval. This is where an integrated supplier shines. In our facility in Keqiao, the design goes from your email to our in-house engraving and sampling department. We aim for 48-hour digital print strike-offs. You get a physical swatch and a high-res digital proof. (Here's a pro tip: always approve a physical strike-off, not just a digital image. Colors on screen lie). This phase includes lab dips for the base fabric if it's dyed. Approval at this stage is your green light for bulk.

Then, bulk production and quality control. The fabric is printed, steamed, washed, and finished. Our on-site, CNAS-accredited lab tests every batch for colorfastness, shrinkage, and composition. Each roll gets a unique QR code linking to its test report—a level of transparency that, frankly, many factories avoid because it exposes flaws. We embrace it. Finally, logistics and shipping. We don't just hand you a bill of lading; we manage the inland transport, customs consolidation in Keqiao's "Silk Road" hub, and can advise on the most cost-effective shipping routes from China to USA to avoid port congestion. This end-to-end control is why our defect rate stays under 2%, compared to an industry average that can be 2-3 times higher.

How to Ensure Print Quality and Consistency Remotely?

Trusting a factory thousands of miles away with your unique design is terrifying. I get it. A blurry logo or shifted color can ruin an entire collection. The fear of "what will actually show up?" keeps many buyers awake at night. But with the right processes and technology, you can have more visibility and control than you might with a local printer.

The old way—sending a JPEG and hoping—is dead. Efficient remote quality assurance is built on a foundation of digital precision, standardized physical validation, and relentless communication. It turns subjective "looks okay" into objective "pass/fail" data. Your goal is to make the production process on our side so transparent that you feel like you're on the factory floor, even from your desk in Los Angeles or Chicago.

Can Digital Tools Replace On-Site QC Visits?

Almost, but not entirely—they amplify and enable smarter visits. For routine orders, a robust digital workflow eliminates the need for constant travel. The cornerstone is a high-definition digital proofing system. We provide proofs with embedded color profiles and dimension markers. You review them on a calibrated monitor—this is crucial. We also send video inspections of bulk fabric rolls. A QC staff member will walk through the warehouse, zooming in on print alignment, showing the full roll length, and highlighting any sections for your direct approval or comment. It's real-time, interactive, and recorded.

For critical milestones, third-party inspection services like SGS or ITS can be your eyes. We facilitate these inspections seamlessly because our in-house QC is already working to the same standards. However, the most powerful tool is data. Our QR code system provides a birth certificate for every meter of fabric. Scanning it gives you access to the specific test results for that batch—breaking strength, colorfastness to washing and light, pH levels. This moves quality from a guessing game to a verifiable fact. A client from Texas sourcing performance fabrics for athletic wear uses this data directly in their marketing, boosting consumer trust.

What Are the Industry Standards for Print Fabric Testing?

You can't manage what you don't measure. Relying on a supplier who says "trust me, it's good" is a major red flag. The industry operates on established, quantifiable standards. For custom prints, the key tests are Colorfastness (to washing, rubbing, perspiration, and light per AATCC or ISO standards), Dimensional Stability (shrinkage after washing), and Fabric Composition verification. For specific end-uses, you might need tests for flammability (like CFR 1610 for US), UV resistance, or antimicrobial properties.

Here’s a quick reference table for common print fabric tests:

| Test | Standard (Typical) | What It Measures | Why It Matters for US Brands |

|---|---|---|---|

| Colorfastness to Wash | AATCC 61 or ISO 105-C06 | Color loss/transfer after simulated washes. | Ensures prints won't fade or stain after consumer laundering. |

| Colorfastness to Light | AATCC 16 or ISO 105-B02 | Resistance to fading from sunlight. | Critical for home textiles or outdoor apparel. |

| Dimensional Stability | AATCC 135 or ISO 5077 | Fabric shrinkage after washing and drying. | Prevents garment from becoming misshapen after first wash. |

| Crocking (Rubbing) | AATCC 8 | Color transfer from dry/wet rubbing. | Prevents prints from staining other surfaces or skin. |

| Fabric Composition | AATCC 20A or ISO 1833 | Verifies % of fibers (e.g., 100% cotton). | Legal labeling requirement (FTC) and ensures performance. |

Working with a supplier like Shanghai Fumao that has a CNAS-accredited lab on-site means these tests are part of our daily workflow, not an expensive, outsourced afterthought. We once caught a potential color bleed issue during pre-production testing for a large batch of printed children's wear destined for the EU market. By adjusting the fixation process, we avoided a costly recall and protected our client's brand reputation. This is the real value of embedded quality control.

How to Navigate Logistics and Tariffs for Fabric Imports?

So, you've got perfect fabric rolls ready in a Chinese warehouse. Now, getting them to your cutting room in the US efficiently and cost-effectively is the final, critical hurdle. This is where many smooth projects hit rough waters. Unforeseen shipping delays, ballooning freight costs, and confusing tariff classifications can erase all your hard-won manufacturing savings. You need a logistics strategy, not just a shipping quote.

Think of logistics as the circulatory system of your supply chain—it must be healthy and predictable. The post-pandemic world has taught us that resilience is key. Efficient navigation here involves understanding Incoterms, choosing the right shipping mode, leveraging trade agreements, and having a clear plan for US customs clearance. Your fabric supplier shouldn't abandon you at the factory gate; they should be a guiding partner through this complex journey.

What Are the Best Shipping Options for Fabric from China?

The choice boils down to the classic triad: Air, Sea, or a combination. Air freight is for true emergencies or extremely high-value, low-volume goods. For most fabric orders, it's prohibitively expensive. Sea freight (FCL/LCL) is the workhorse. Full Container Load (FCL) is cost-effective for large orders (e.g., 10+ tons). Less than Container Load (LCL) is perfect for smaller batches, where you share container space. The trade-off is time: ocean transit can be 30-45 days from port to port.

A growing option is rail freight via China-Europe routes, which can be a good middle ground in terms of cost and speed (around 18-22 days), though its end-points and reliability for US-bound goods can be complex. Your decision matrix should consider order volume, urgency, and cost sensitivity. We often advise clients to use a hybrid model: ship the bulk of your seasonal order via sea (LCL or FCL) 12 weeks ahead, and air freight a small top-up quantity closer to launch if needed. Crucially, use Incoterms to define responsibility. We prefer FOB (Free On Board) as it gives you, the buyer, control over choosing your freight forwarder and managing the main ocean/air leg, which is often where the best rates are negotiated. We handle everything to the port of departure.

How Can US Brands Minimize Tariff Costs Legally?

Tariffs are a cost of doing business, but they shouldn't be a surprise. The key is accurate Harmonized System (HS) code classification. A fabric's HS code determines its duty rate. For example, the duty for printed cotton fabric (HS code 5208.52) is different from printed polyester (HS code 5407.52). Misclassification can lead to overpayment, penalties, or customs holds. We provide a preliminary classification based on the fabric's composition, weight, and construction, but you must have your customs broker verify it.

The most powerful tool is provenance. While "Section 301" tariffs apply to many Chinese-origin goods, if your fabric undergoes a "substantial transformation" in a third country (e.g., weaving in China but dyeing and printing in Vietnam or Cambodia), it may qualify for that country's origin and avoid the extra tariffs. We have cooperative finishing partners in ASEAN countries for clients who need this strategic diversification. Furthermore, ensure your supplier provides all necessary documentation for customs clearance, including a detailed Commercial Invoice, Packing List, and Certificate of Origin. Transparency is your friend at the border. A client importing technical outerwear fabrics saved nearly 5% on landed costs simply by working with us to ensure their paperwork meticulously matched the product description and HS code, avoiding a costly customs reclassification and delay.

Why Choose an Integrated Supplier Over a Trading Company?

This is the million-dollar question. A trading company is a middleman; an integrated supplier is a partner with skin in the game. When problems arise—and they will—a trading company points fingers between the mill, the printer, and the dyer. An integrated supplier points at a solution because they control the process. The difference is accountability and agility.

The fragmented nature of the textile industry in places like Keqiao is both its strength and its biggest pitfall for foreign buyers. You can find amazing specialists for every step, but coordinating them is a full-time job riddled with communication breakdowns and buck-passing. An integrated partner consolidates complexity, giving you a single point of contact, responsibility, and quality control from yarn to shipment. For custom printed fabrics, where coordination between base fabric quality and print application is critical, this is not a luxury; it's a necessity.

How Does Vertical Integration Reduce Risks and Delays?

Risk reduction is direct and tangible. First, communication risk. With one team managing the entire flow, your feedback loops are short. A color adjustment needed after printing can be communicated to the dyeing department in the same compound in hours, not days. Second, quality risk. When weaving, dyeing, and printing are under one roof (or under tightly managed partnership agreements), the quality standards are unified. The base fabric is made with the printing process in mind. There's no blaming the "other factory" for a fabric defect that caused a print flaw.

Third, timeline risk. This is huge. In a disconnected chain, a delay at the dyeing factory cascades, pushing back the printer's schedule, who then blames the dyer. An integrated supplier absorbs these fluctuations internally. They can re-prioritize lines, shift manpower, and work overtime on critical path items because it's all their operation. For instance, in early 2023, a Portland-based sustainable apparel brand needed a rush order of custom-printed organic cotton twill. Because we control our weaving and printing schedules in sync, we were able to fast-track the yarn sourcing, weave the greige fabric, and slot it into the print queue ahead of schedule, delivering the entire order 2 weeks faster than a multi-vendor setup ever could. That's the power of vertical integration in action.

What Services Should a True One-Stop Shop Offer?

Beware of suppliers who claim to be "one-stop" but are just brokers with a nice website. A genuine partner offers a connected, transparent pipeline. Here’s your checklist:

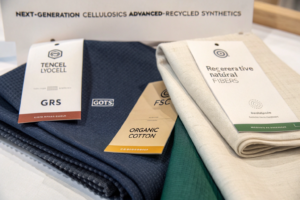

- In-House or Captive Partner Control Over Key Stages: Weaving/Knitting, Dyeing, Printing (Digital & Rotary), Finishing (coating, laminating, softening), and Quality Inspection. At Shanghai Fumao, we have our own large-scale weaving factory and cooperative, dedicated facilities for every other critical step, all managed by our team.

- Transparent Development Process: They should guide you from concept. This includes yarn sourcing advice, lab dip and strike-off development in 48-72 hours, and tech pack review.

- On-Site Laboratory Testing: Not just sending out for tests, but having a certified lab to do pre-production and bulk testing. This allows for immediate corrective action.

- Supply Chain Finance Stability: Ask about their banking relationships. A financially stable supplier won't demand 100% upfront payment and can handle large orders without cash flow hiccups, which is a hidden risk with smaller traders.

- Logistics and Export Management: They should handle export documentation, inland transportation to the port, and have partnerships with reliable freight forwarders to offer you competitive shipping solutions. The best ones, like us, have experience with the specific challenges of shipping textiles to international markets and can advise on the optimal route and Incoterm for your situation.

Choosing this model means you're not just buying fabric; you're buying peace of mind, predictability, and a partner invested in your success as much as their own.

Conclusion

Efficiently sourcing custom printed fabrics from China is a definable, manageable process, not a leap of faith. It hinges on strategic planning around immutable production cycles, leveraging digital tools for remote quality assurance, understanding the intricacies of international logistics and tariffs, and, most importantly, selecting the right type of partner. By moving from a transactional relationship with a faceless factory or a disengaged trading company to a collaborative partnership with an integrated, transparent supplier, US brands can transform their supply chain from a source of stress into a competitive advantage.

The goal is to make the complex simple, the distant feel close, and the unpredictable become reliable. It's about working with a partner who speaks your language, understands your market's demands, and has the operational depth to deliver on promises. In today's fast-paced fashion world, agility and reliability are currency.

If you're ready to streamline your fabric sourcing and turn your custom print ideas into flawless, on-schedule reality, let's talk. We at Shanghai Fumao are built to be that partner. We combine the deep resources of Keqiao's textile ecosystem with the focused, client-driven service you deserve. To explore how we can support your next collection, reach out to our Business Director, Elaine. She and her team are experts in guiding brands through efficient production. You can contact her directly at elaine@fumaoclothing.com to start a conversation about your specific needs.