You just got a fantastic price quote from an Asian fabric supplier: $3.50 per meter for that premium organic cotton twill. You're ready to order 10,000 meters, thinking your total cost is $35,000. But then, a hidden fee pops up. Then another. When the fabric finally lands in your warehouse, the actual cost is closer to $5.80 per meter. Your entire margin has evaporated. This scenario isn't a mistake; it's a costly misunderstanding of what price really means in global trade. The quoted "FOB price" is just the starting line, not the finish line.

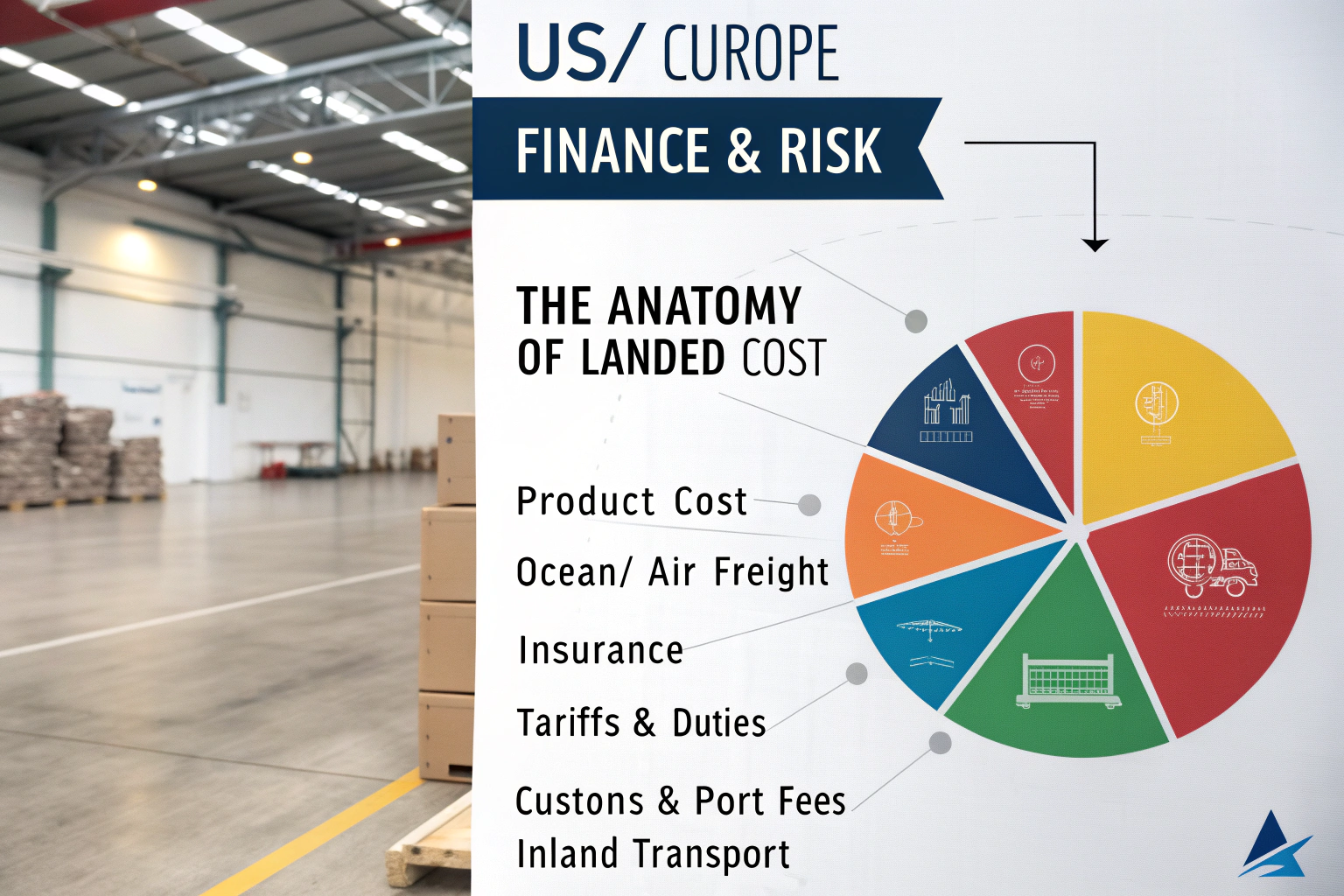

Your total landed cost is the complete sum of all expenses incurred to get your fabrics from the supplier's factory floor to your receiving dock, ready for production. It's the only number that matters for profitability. Calculating it accurately requires you to account for a complex web of variables beyond the product price: international freight, insurance, tariffs and duties, customs broker fees, port charges, inland transportation, and the often-overlooked cost of capital and risk. Missing even one component can turn a winning order into a financial loss.

Many importers, especially those new to sourcing from Asia, fall into the trap of comparing only the FOB (Free On Board) prices. They later face "sticker shock" from logistics and compliance costs. A seasoned importer knows that the true cost is buried in the details of the shipment's journey. At Shanghai Fumao, we guide our clients through this calculation from the very first quote because we see our role as partners in your supply chain, not just sellers of fabric. Let's build a framework to make these hidden costs visible and manageable.

What Are the Hidden Components Beyond the FOB Price?

Your supplier says, "FOB Shanghai $3.50/m." You think your cost is locked. But FOB only means the fabric is loaded onto the ship at the origin port. Everything that happens after that—the voyage, the protection, the legal permission to enter your country, and the final delivery—is your cost and responsibility. These are not hidden to those who know where to look; they are simply the standard, yet frequently un-budgeted, chapters of the import story.

The hidden components beyond the FOB price primarily consist of Logistics & Freight, Insurance, Import Duties & Taxes, and Destination Handling fees. Think of the FOB price as the ticket to the concert. The landed cost includes the ticket, plus the Uber ride, the parking fee, the merch you buy, and the food—it's the full night out. For example, we worked with a US-based apparel startup in Q3 2023. They were thrilled with a low FOB price on a recycled nylon order until they realized the high density of the fabric led to much higher ocean freight charges than they'd estimated, which then increased their total duty bill (since duty is calculated on CIF value). We helped them re-calculate using a different, more freight-efficient weave structure, saving 18% on the total landed cost.

How do Incoterms like FOB, CIF, and DDP define cost responsibility?

Incoterms are the international rulebook that defines who pays for what and who bears the risk at every stage of the journey. Getting these wrong is a classic and expensive error.

- FOB (Free On Board): Your cost responsibility starts the moment the fabric crosses the ship's rail at the origin port. You pay for main freight, insurance, and all destination costs. The supplier handles everything to get it loaded.

- CIF (Cost, Insurance & Freight): The supplier pays for the main freight and minimum insurance to the destination port. You take over at the port, paying for unloading, customs clearance, duties, and final delivery. Risk transfers to you during ocean transit.

- DDP (Delivered Duty Paid): The supplier's quote aims to cover everything to your designated address, including duties and taxes. This seems simple but is complex for them to quote accurately in a foreign market.

My strong recommendation for fabric importers: Use FOB. Why? It gives you control. You choose your own freight forwarder, negotiate rates, and control the insurance and customs clearance process. With CIF or DDP, the supplier controls these legs, often marking up the costs. In early 2024, a UK client came to us after a bad experience where a supplier's CIF quote used a slow, indirect shipping route to keep their freight cost low, but it delayed the client's production by 3 weeks. The "savings" cost them far more in missed deadlines. Learning to choose the right incoterm for your textile imports is critical, and resources like the International Chamber of Commerce's guide are essential.

What are the typical destination port and customs clearance fees?

These are the "surprise" fees that greet your shipment when it arrives. They vary by country and port but generally include:

- Terminal Handling Charges (THC): Fee for moving the container from the ship to the port yard.

- Customs Clearance Fee: Your customs broker's charge for filing paperwork and liaising with authorities.

- Merchandise Processing Fee (MPF) / Similar: A government fee for processing the entry (e.g., in the US, it's 0.3464% of shipment value, min $29.22, max $614.35).

- Harbor Maintenance Fee (HMF) / Port Fees: A US fee of 0.125% of the cargo value.

- Pricing and Handling (PTH): Fee for handling the container from the port yard to the truck.

Let's put numbers to it. For a standard 40-foot container (FCL) of fabric worth $50,000 arriving in Los Angeles, these destination fees can easily add $1,800 to $2,500 on top of the ocean freight. For smaller Air Freight shipments, per-kilo handling and clearance fees apply. The key is to get a detailed estimate from a licensed customs broker before you ship. We always connect our clients with trusted forwarder partners. An industry forum like The Fashion Network often has threads where importers share real-world examples of US customs clearance fees for textiles, which can be a valuable reality check.

How to Accurately Estimate Freight and Logistics Costs?

"Just ship it" is where budgets go to die. Freight costs are volatile, mode-dependent, and full of surcharges. A quote for $2,800 ocean freight can balloon to $3,900 with peak season surcharges, bunker adjustment factors, and port congestion fees. Estimating this isn't about guessing; it's about gathering the right data and understanding the logistics landscape.

To accurately estimate freight costs, you need three core pieces of information: 1) Shipment Details (exact weight and volume of your cargo), 2) Route & Mode (origin/destination ports, choice of sea or air), and 3) Current Market Conditions (spot rates, seasonal surcharges). You then request formal quotes from multiple freight forwarders, ensuring they are "all-in" quotes that include all anticipated surcharges. At Shanghai Fumao, we provide our clients with precise gross weight, net weight, and cubic volume (CBM) for their orders. For instance, we recently helped a Canadian activewear brand compare the landed cost of air vs. sea for a urgent prototype fabric. By providing exact carton dimensions, we showed that while air was 5x more expensive, the 5-week time savings protected their product launch, making it the profitable choice.

Should I choose Sea (LCL/FCL) or Air Freight for my fabric shipment?

This is a classic cost vs. time equation. Let's break it down with a table:

| Mode | Typical Transit Time (China to US West Coast) | Cost Relative to Sea | Best For |

|---|---|---|---|

| Air Freight | 5-10 days | 4x - 8x higher | Small batches (<500kg), high-value fabrics (e.g., luxury silks, technical prototypes), urgent samples or production-saving orders. |

| Sea FCL | 25-35 days | Lowest per-unit cost | Large, full orders (enough to fill a 20' or 40' container). Offers more control and security. |

| Sea LCL | 30-40 days | Higher per-CBM than FCL, but lower total than air | Medium-sized orders that don't fill a container. You pay for the volume you use (CBM). |

The Rule of Thumb: If your fabric can wait, ship by sea. If your production line will stop, ship by air. A practical example: In November 2022, a European client needed 3,000 meters of a specific velvet for holiday season production. Ocean transit was too risky with port delays. We coordinated an air shipment for the fabric and their trimmed the order to just the essential quantity. The higher freight cost was factored into their final product pricing and was justified by capturing the seasonal sales window. For deeper insights, the journal Apparel Logistics Today publishes analyses on calculating air versus sea freight for fashion inventory.

How do I calculate chargeable weight for air and sea freight?

This is a non-negotiable calculation. Carriers charge you based on whichever is greater: the actual gross weight or the volumetric weight.

- Air Freight:

Volumetric Weight (kg) = Length(cm) x Width(cm) x Height(cm) / 6000. If vol. weight > actual weight, you pay based on vol. weight. - Sea LCL:

Volumetric Weight (CBM) = Length(m) x Width(m) x Height(m). You pay per CBM. For FCL, you pay for the entire container regardless of weight (within legal limits).

A real-life tip from our warehouse: Pack efficiently! Fabric rolls are dense, but if packed loosely in large cartons, they can "weigh" far more in volumetric terms. We optimize carton sizes to minimize CBM. For a recent shipment of lightweight chiffon, the actual weight was 800kg, but the volumetric weight was 1,100kg. We re-packed from 20 large cartons into 30 smaller, tighter ones, reducing the volumetric weight to 950kg, saving the client over $300 on air freight. Understanding how to reduce volumetric weight in textile shipping is a key skill, and logistics blogs like Flexport's resource center offer great practical guides.

How to Calculate Duties, Taxes, and Tariffs for Textiles?

This is where geopolitics meets your bottom line. A fabric's duty rate is its tax for entering a country, determined by its harmonized system (HS) code, country of origin, and any applicable trade agreements or tariffs. Misclassifying your fabric can lead to overpayment, audits, or seizure. You must get this right.

Calculating duties and taxes involves a three-step process: 1) Identify the correct HS Code for your fabric (e.g., 5208.11 for plain weave cotton >85%, 5407.42 for woven polyester), 2) Determine the duty rate applicable to that code for your importing country (check the official customs tariff schedule), and 3) Apply the rate to the dutiable value (typically the CIF value—Cost, Insurance, and Freight). The formula is: Duty = (CIF Value) x (Duty Rate %). Then, add any local taxes (like VAT or GST) on the sum of the CIF value + Duty.

Crucial Example: For the US, most apparel fabrics have duty rates between 5% and 17%. However, under Section 301, many Chinese-origin textiles have an additional 7.5% to 25% tariff. Let's say you import $50,000 CIF of polyester fabric from China. The base duty might be 10% ($5,000). With a 7.5% Section 301 tariff, you pay an extra $3,750. Your total duty is now $8,750. This is why Shanghai Fumao has invested in production in our Vietnam partnership facility for many of our US-bound clients, as fabrics of Vietnamese origin are not subject to these additional 301 tariffs, offering massive landed cost savings.

What is the HS Code, and why is it critical for duty calculation?

The Harmonized System (HS) Code is a 6- to 12-digit universal numeric language for classifying traded products. The first six digits are global; subsequent digits are country-specific. It is critical because it directly determines your duty rate. An incorrect code can mean paying a much higher duty or facing penalties for underpayment.

Example: A "woven fabric of cotton, weighing more than 200g/m²" might fall under 5209.11. If you mistakenly classify a heavier canvas as a lighter fabric under 5208.11, you could be audited. The responsibility for correct classification ultimately lies with the importer of record (you or your broker). We assist by providing detailed, accurate product descriptions on the Commercial Invoice, which is the primary document customs uses. The U.S. International Trade Commission (USITC) website provides the official Harmonized Tariff Schedule (HTS) to look up codes and rates. It's dense, so using a licensed customs broker is highly advised for final determination.

How do trade agreements and punitive tariffs affect my final cost?

They can make or destroy your cost advantage.

- Trade Agreements (e.g., USMCA, ASEAN FTAs): Can reduce or eliminate the base duty rate for goods originating in member countries. You must obtain and provide a Certificate of Origin to claim this benefit.

- Punitive Tariffs (e.g., U.S. Section 301 on China): Impose additional tariffs on top of the base duty, as described above. This is a major cost driver.

Actionable Strategy: Conduct sensitivity analysis. Calculate your landed cost under three scenarios: 1) With full punitive tariffs, 2) With tariff exclusions (if any apply), 3) Sourcing the same fabric from a non-tariff country (like Vietnam or Pakistan). For many of our clients, scenario 3 has become the default. In 2023, we helped an American workwear brand shift production of their heavy-duty polyester-cotton blends from our Keqiao facility to our partnered Vietnam unit. The fabric cost increased slightly (by $0.15/m), but the avoidance of the 25% Section 301 tariff reduced their total landed cost by 17%, a decisive competitive edge. Keeping abreast of current Section 301 tariff updates for textiles is essential, and law firm trade blogs often provide the most timely analyses.

What Are the Often-Forgotten Costs of Risk and Capital?

You've summed up product, freight, and duty. You think you're done. But what about the cost of the money tied up while your fabric is on the water for 30 days? What if the shipment is delayed, and your production line sits idle? What if the goods are damaged, and the insurance claim is disputed? These "soft costs" don't appear on a freight quote but directly impact your profitability and operational resilience.

The often-forgot costs are the Cost of Capital (finance charges for money tied up in inventory-in-transit) and the Cost of Risk (potential losses from delays, damage, quality issues, or compliance failures). These are not line-item invoices but rather impacts on your cash flow, efficiency, and contingency budgets. A large order with a 60-day production lead time plus 35-day ocean transit means your capital is committed for over 3 months before you even start cutting the fabric. If your cost of capital is 8% annually, that's a real financial cost.

For example, we advise clients on production scheduling to align with Chinese manufacturing cycles. Ordering during the slower periods (June-July, Nov-Dec) might mean slightly faster production, freeing up capital sooner. One of our long-term EU clients, a fashion brand, plans their entire collection timeline around Chinese New Year. They complete pre-production with us 6 weeks before the holiday shutdown. This allows production to start the day factories reopen, minimizing the capital tied up in idle waiting time. This strategic timing is a form of risk and capital cost reduction. (Here’s an inside tip: building a buffer for unexpected delays is not poor planning—it's essential risk management.)

How do I quantify the cost of inventory financing during transit?

Use this straightforward formula:

Cost of Capital = (Order Value + Incurred Freight/Duty Costs) x (Annual Cost of Capital %) x (Transit Time in Days / 365)

Example: Your fabric order and incurred costs total $100,000. Your company's cost of capital (or interest rate on a line of credit) is 6% per year. Ocean transit is 35 days.

Cost = $100,000 x 0.06 x (35/365) = $100,000 x 0.06 x 0.0959 ≈ $575

This means you effectively pay an extra $575 to have that inventory floating on the ocean. For air freight (10 days), this cost drops to about $165. While air freight is more expensive upfront, the reduced cost of capital and faster inventory turnover can sometimes justify it for high-margin or fast-moving items. This is a key part of any total cost of ownership analysis for imported goods.

What financial risks should I budget for, and how?

You should budget contingencies for:

- Transit Delay Risk: Budget 5-10% extra time in your production schedule. The financial impact is the cost of air-freighting a partial shipment to save the line or the lost sales from a delayed product launch.

- Quality/Compliance Risk: Despite inspections, a bulk lot may have issues. Budget 1-3% of the order value for potential claims, re-work, or discounted sales. Our 98% client pass rate from our in-house CNAS lab aims to push this risk toward zero.

- Currency Exchange Risk: If paying in a foreign currency (e.g., USD to CNY), fluctuations can change your product cost. Use forward contracts to lock in rates if the order is large.

The best practice is to create a Landing Cost Worksheet that includes a contingency line item, typically 2-5% of the total estimated landed cost. This isn't money you expect to spend, but it's a prudent reserve. Forums like Import Yeti are filled with stories from importers about unexpected costs, providing a valuable resource for building a contingency budget for importing from Asia.

Conclusion

Calculating the total landed cost for fabrics from Asia is not an accounting exercise—it's the foundation of your sourcing strategy and product profitability. It forces you to look beyond the tempting FOB price and embrace the full complexity of global logistics. By meticulously accounting for the product, freight, duties, and the hidden costs of risk and capital, you transform from a reactive payer of invoices into a proactive manager of your supply chain.

The goal is to make informed, comparative decisions. The cheapest FOB supplier can become the most expensive partner once all costs are tallied. Conversely, a slightly higher FOB price from a supplier who provides accurate data, optimal packaging, and guidance on compliance can yield the lowest, most predictable landed cost and the strongest partnership.

Stop comparing just prices. Start comparing true costs. At Shanghai Fumao, we provide more than fabric; we provide cost clarity. From the initial sample to the final landed cost spreadsheet, we partner with you to navigate Incoterms, optimize logistics, and leverage our multi-country production to minimize tariffs. Let us help you build a resilient and cost-optimized supply chain. For a detailed landed cost analysis tailored to your next fabric project, contact our Business Director, Elaine. She and her team will work with you to map out every variable and ensure your import is as profitable as it is seamless. Reach out to Elaine at: elaine@fumaoclothing.com.