As a fabric supplier who has spent over two decades in Keqiao's textile heartland, I hear one question more than any other from my European and American clients: “What’s next in sustainable fabrics?” It’s not just about finding a green material anymore. It’s about finding the material that will define the next season, meet stringent regulations, and captivate conscious consumers. The pressure is real for brands that need to stay ahead.

So, what are the latest trends in eco-friendly fabrics for 2026? The answer moves beyond simple material swaps into a new era of innovation. The focus for 2026 is on circularity, biodiversity-driven materials, and hyper-transparency enabled by digital tech. Forget just recycled polyester; we’re talking about fabrics made from agricultural waste, self-decomposing blends, and supply chains you can track with a scan. This shift is driven by tighter EU regulations like the ESPR and consumers who demand proof, not just promises.

If you're planning your 2026 collections, understanding these trends is no longer optional—it's a competitive necessity. The brands that integrate these next-gen solutions will not only future-proof their supply chains but also capture a growing market segment. Let's break down the four key directions that will dominate sourcing conversations.

How to Source Circular Economy Fabrics in China?

The buzzword “circular” is getting real in 2026. It’s no longer just about recycling a bottle into a shirt. The real trend is about closed-loop systems where the end-of-life garment becomes the raw material for a new one, right here in the supply chain cluster. Brands are asking for fabrics designed for disassembly and recyclability from the get-go. I’ve seen a massive uptick in requests for mono-material constructions (like 100% recycled polyester knits) because they are simpler to recycle. In early 2024, a German outdoor brand partnered with us to develop a fully recyclable tent fabric system. The challenge wasn’t the recycled nylon; it was finding a durable, waterproof coating that wouldn’t contaminate the recycling stream. After 3 months of R&D with our coating factory, we settled on a specific PU formulation that can be chemically stripped, allowing the base fabric to be cleanly reprocessed.

What does "circular fabric" actually mean for your supply chain?

It means rethinking your entire product lifecycle with your supplier. For you, the buyer, it translates to three concrete demands: 1) Traceable Recycled Content: You need proof. We’re moving past generic “recycled” claims to certified, mass-balanced tracked content. This requires suppliers to have certified sources and robust documentation. 2) Design for Recycling: This involves technical choices your fabric partner must guide you on. For instance, choosing thread and label materials compatible with the main fabric, or avoiding permanent lamination that creates a non-recyclable composite. 3) End-of-Life Partnerships: Progressive suppliers are now offering take-back programs or connections to recycling partners. At Shanghai Fumao, we’ve initiated pilot programs with several European clients, collecting their production cut-offs to recycle back into new yarns for their future orders, creating a mini-loop.

Which recycled materials offer the best performance-to-cost ratio?

This is the daily debate on the factory floor. Let’s be brutally honest: not all recycled fabrics are created equal, and the price varies wildly. Here’s a quick breakdown of the current landscape based on our order books:

| Material | Key Advantage for 2026 | Performance Consideration | Cost Trend (vs. Virgin) |

|---|---|---|---|

| Recycled PET (rPET) from Ocean Plastic | Powerful marketing story, high consumer recognition. | Durability can match virgin PET; now widely available in fine deniers for lightweight apparel. | Premium (~15-25% higher), but stabilizing as supply grows. |

| Post-Consumer Recycled Cotton | True circular solution, reduces water/land use drastically. | Fiber length shortens; often needs blending with recycled polyester for strength. | Highly variable; depends on color sorting. Pre-consumer waste is cheaper. |

| Chemically Recycled Nylon 6 | Game-changer. Can infinitely recycle waste (including carpets) back to virgin-quality fiber. | Performance is identical to virgin nylon—perfect for high-end sportswear and lingerie. | High premium (~30-50%), but costs are dropping as new plants come online in China. |

My personal advice? For high-volume basics, rPET is your safest bet. The supply chain is mature, the quality is consistent, and the price is becoming competitive. For a performance edge, look into chemically recycled nylon. A Swedish swimwear brand we worked with in Q3 2023 made the switch, and despite a 35% fabric cost increase, they commanded a 50% higher retail price due to the innovative story. The key is to understand the lifecycle assessment of recycled versus virgin synthetics to make an informed choice. Also, when navigating certifications for recycled content claims, always ask for the specific certificate (e.g., RCS, GRS) and transaction certificate for your batch.

Are Bio-Based Fabrics Beyond Cotton and Hemp?

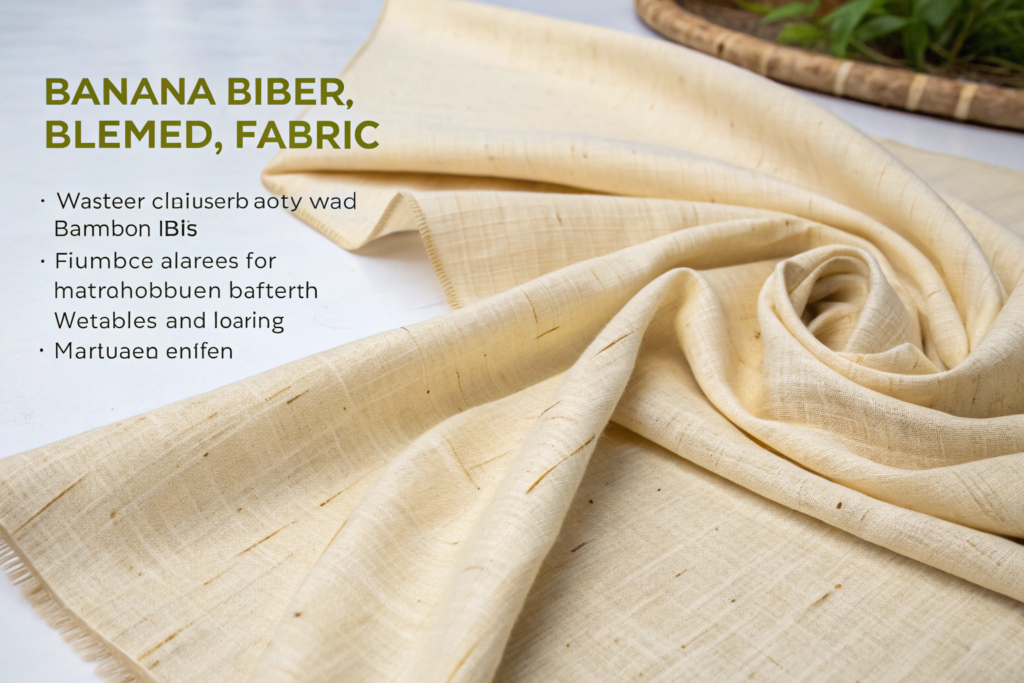

Absolutely. While organic cotton and hemp are staples, the 2026 bio-based revolution is about “next-gen” feedstocks. We’re leveraging agricultural by-products and lab-grown materials to create fabrics without competing for food resources or arable land. Our R&D team is flooded with samples made from pineapple leaves, banana stems, and even algae. The excitement is palpable. For example, in late 2023, we developed a small-batch run of banana fiber blended with BAMSILK (our bamboo silk) for a French luxury house. The result was a linen-like fabric with a stunning, natural slub texture and a beautiful drape, but with a significantly lower water footprint than conventional linen. The client’s pre-order campaign sold out in 48 hours.

What are the most viable bio-based fabrics for commercial scale?

“Viability” is the keyword. Many novel materials are stuck in the lab. The ones breaking into commercial production share two traits: a reliable waste stream and scalable processing. Here are the front-runners for 2026:

- Agricultural Waste Fibers: Orange Fiber (from citrus juice by-product) and Circulose (from cotton waste pulp) are gaining traction. They are often processed into a lyocell-type fiber, offering a soft, versatile base. The challenge is consistent feedstock quality, which major producers in China are now solving.

- Lab-Grown Biopolymers: PLA (Polylactic Acid) from corn sugar is big. It’s compostable under industrial conditions, making it ideal for disposable textiles or blended applications. We’re testing PLA blends for summer tees—they feel incredibly cool and dry.

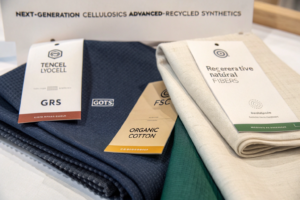

- Next-Gen Regenerated Cellulose: Lyocell (Tencel) remains the gold standard, but now it’s being sourced from sustainably managed bamboo (not the old, chemically-intensive viscose process). Our BAMSILK uses a closed-loop lyocell process, and demand grew 40% last year alone.

How do the costs and minimums compare to conventional natural fibers?

This is the hurdle. Bio-based fabrics are rarely cheap, and minimums can be high because they require dedicated production runs. Let’s compare:

- Organic Cotton: Premium of ~20-40% over conventional. MOQs are similar (usually 1000kg+ per color).

- Hemp: Premium of ~25-50%. MOQs can be higher due to fewer specialized spinners.

- Novel Bio-Based (e.g., Orange Fiber): Premium of 100-300%. MOQs are critical—you might be looking at 2000kg minimums for a spin, which is a big commitment.

The strategy? Blend and conquer. Start by blending a novel bio-fiber with a workhorse like organic cotton or recycled polyester. This reduces cost, mitigates supply risk, and lets you tell a compelling “X% made from innovative material” story. We always advise clients to explore the emerging bio-based materials landscape cautiously and to start with a pilot order to test performance and market reception before scaling.

How Can Digital Tech Verify Your Fabric's Green Claims?

Trust is the new currency. In 2026, saying “this is eco-friendly” isn’t enough. You need immutable, digital proof. This trend, called digital product passports (DPP) in the EU, is becoming a reality. It means every meter of fabric could have a unique digital twin—a QR code or NFC tag that tells its entire life story: origin of raw materials, water and carbon footprint, chemical compliance, and recycling instructions. We’ve invested heavily in this. Our CNAS lab tests are now linked directly to QR codes on our rolls. A Danish children’s wear brand scanned our code last month and accessed the full Oeko-Tex Class I test report for the exact batch they received within seconds. Their head of sourcing told me it cut their onboarding verification time from two weeks to two minutes.

What is a Digital Product Passport and why should you care?

Think of it as a birth certificate and biography for your fabric, stored on a blockchain or secure database. For you, it solves three major pain points:

- Compliance: It automates reporting for regulations like the EU’s Digital Product Passport, saving you countless hours of manual data collection.

- Consumer Engagement: That same QR code can be sewn into your garment, allowing the end-consumer to see the provenance story, which builds brand loyalty and justifies a premium price.

- Supply Chain Diligence: It prevents greenwashing in your own chain. You can see if your recycled polyester yarn truly came from the certified supplier your fabric mill promised.

Implementing this requires a supplier with integrated systems. At Shanghai Fumao, we’ve built traceability from our dyeing partners upwards. When you get a tech pack from us, the DPP data is part of the package.

Which technologies are accessible for mid-sized brands?

You don’t need a multi-million dollar budget. Start with these accessible steps:

- Blockchain-Linked Certificates: Platforms now offer affordable, batch-level blockchain recording for certificates like GRS or GOTS. This proves your certificate is real and unique to your order.

- Supplier-Integrated Platforms: Ask your supplier what they use. We use a platform that allows clients limited read-only access to their order’s production and test data in real-time.

- Life Cycle Assessment (LCA) Tools: Simplified, brand-friendly LCA tools are emerging. You input your fabric composition and processes (which a transparent supplier should provide), and it generates a footprint report.

The first step is to start a conversation with your fabric supplier about supply chain transparency tools. The best partners will already be on this journey. Furthermore, educating yourself on how blockchain is transforming textile supply chain verification will help you ask the right questions and choose a forward-thinking partner.

What Are the Newest Functional Eco-Friendly Finishes?

Sustainability isn’t just about the base fiber—it’s about making that fiber last longer and perform better, reducing the need for frequent replacement. The trend for 2026 is durability-enhancing finishes that are themselves environmentally benign. We’re phasing out PFC-based water repellents (a major red flag for EU regulations) and moving to PFAS-free, bio-based durable water repellents (DWR). Even more exciting are finishes derived from natural sources. Our coating factory has perfected a chitosan-based antimicrobial finish sourced from crustacean shells. It’s naturally antibacterial and odor-resistant, perfect for activewear, and it’s completely biodegradable. (Here’s a secret from the lab: it took us 17 iterations to get the binding agent right so it wouldn’t wash out after 5 cycles).

How do you ensure a finish is truly "green"?

You have to be a detective. “Green” is a marketing term until proven otherwise. Here’s our 3-point checklist we share with clients:

- Chemistry: Ask for the safety data sheet (SDS) and look for ZDHC MRSL compliance. Specifically, ask if it’s PFAS/PFC-free. A true green finish will proudly advertise this.

- Certification: Look for finishes certified by Bluesign® or Oeko-Tex STeP. These are third-party verifications of environmental and safety standards in the application process.

- Performance Durability: A finish that washes out in 10 cycles is not sustainable—it leads to early garment discard. Ask for AATCC or ISO test reports showing performance after 30, 50, or even 100 washes. A durable finish extends garment life.

Which innovative finishes add the most value to basic eco-fabrics?

This is where you can differentiate a simple organic cotton tee. Here are two high-impact finishes:

- Natural Enzyme Washing for Recycled Cotton: Recycled cotton can feel coarse. Using natural enzymes (like cellulase) instead of harsh chemicals to stone-wash it creates a super-soft hand feel with minimal environmental impact. We did this for a Los Angeles-based streetwear brand, and it became their best-selling tee, despite a 15% price hike.

- Plant-Based Wrinkle Resistance: Traditional wrinkle-free finishes use formaldehyde. New technologies use citric acid or modified plant starches. We applied a plant-based finish to a linen-viscose blend for a UK retailer, and it reduced ironing needs by 80%, a huge selling point for their busy customer base.

To stay ahead, I recommend you regularly review updates to the ZDHC Manufacturing Restricted Substances List to ensure your finishes are compliant. Also, investigating the science behind PFAS-free durable water repellents will help you evaluate suppliers’ claims more effectively and choose the right partner like Shanghai Fumao for your functional needs.

Conclusion

The landscape of eco-friendly fabrics for 2026 is dynamic and exciting, moving from basic material substitution to a holistic system of circular design, biodiverse sourcing, digital verification, and intelligent finishing. Success won’t come from chasing every new material but from building a strategic, transparent, and collaborative partnership with a fabric supplier who understands both the trends and the ground realities of production. It’s about making choices that are good for the planet, credible to your customer, and viable for your business.

As you plan your 2026 collections, consider these trends not as hurdles, but as opportunities to innovate, differentiate, and build a more resilient brand. If you're looking to translate these 2026 eco-fabric trends into tangible, high-quality fabrics for your next collection, we should talk. My team and I at Shanghai Fumao live and breathe this innovation every day in Keqiao. For a direct conversation about how we can co-create your sustainable line, from concept to bulk delivery with full digital traceability, please reach out to our Business Director, Elaine. She can connect you with our R&D and sustainability experts. You can email her directly at: elaine@fumaoclothing.com.