You've placed a bulk fabric order—thousands of meters, a significant investment, and the foundation of your entire collection. Then, the nightmare scenario hits: inconsistent dye lots, weaving defects in the middle of the roll, or shrinkage that ruins your garment patterns. The financial loss is staggering, but the reputational damage and missed delivery windows are worse. For global brands, inconsistent quality from overseas suppliers isn't just an annoyance; it's an existential threat to the supply chain.

At Fumao Fabric, we believe quality control isn't a department; it's the foundational principle of our integrated manufacturing process. We ensure quality for bulk fabric orders through a proprietary "Four Shield" system: 1) Pre-Production Specification Lockdown, 2) In-Process Real-Time Monitoring, 3) Post-Production 360° Inspection, and 4) Digital Traceability & Documentation. This system embeds quality checks at every physical and digital touchpoint—from yarn sourcing to the sealed container—turning potential defects into prevented data points and guaranteeing a 98% client pass rate on first-time bulk deliveries.

Forget the old model of a single QC check at the end. Our system is proactive, not reactive. We intercept issues before they become meters of wasted fabric. This guide will pull back the curtain on exactly how our vertically-integrated structure in Keqiao allows us to execute this level of control, sharing specific protocols, equipment, and real case studies that demonstrate how we turn the complex challenge of bulk quality into a predictable, reliable outcome for our partners.

What Happens During the "Pre-Production Specification Lockdown"?

The single biggest cause of bulk quality failure is ambiguity. Vague descriptions like "navy blue" or "soft hand feel" are recipes for disaster. Our first shield, Specification Lockdown, is about eliminating all interpretation before a single meter is woven.

This phase is a collaborative engineering session. When a US sportswear brand placed a 10,000-meter order for a custom recycled polyester double-knit in Q3 2024, we didn't just accept their tech pack. Our technical team held a 2-hour video conference to review every line:

- Color: We moved from "Charcoal Grey" to a precise Pantone TPX 19-4005 standard and agreed on a DE<1.0 under D65 lighting as the acceptable color difference for bulk.

- Weight & Composition: We verified the target 280 GSM +/- 3% and confirmed the 85% rPET / 15% Spandex blend through a yarn supplier certificate before ordering.

- Physical Tests: We agreed on specific pass/fail thresholds: Shrinkage <3%, Pilling 4+ (Martindale), and Colorfastness to washing 4+. These weren't aspirations; they were contractually binding specifications attached to the purchase order.

This "Lockdown" creates a Golden Sample—a physical, signed-off swatch that is the absolute standard for the entire order. It's stored in our climate-controlled sample room and scanned into our digital system. Any deviation in bulk is measured against this single source of truth.

How Do You Control Quality at the Raw Material Stage?

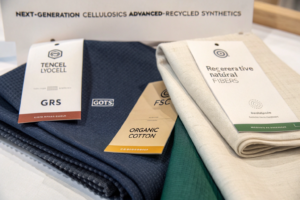

You cannot make high-quality fabric from inconsistent yarn. Our control starts upstream. For the double-knit order, we didn't just buy "recycled polyester chips." We sourced GRS-certified chips from a specific supplier (documented), and our in-house lab tested the incoming yarn for:

- Denier/Count Consistency: Using an electronic yarn count tester to ensure even thickness.

- Tenacity & Elongation: To prevent breakage during high-speed knitting.

- Color (for dope-dyed yarns): Spectrophotometer check against the standard.

This raw material certification is a non-negotiable gate. In early 2024, we rejected a 2-ton batch of organic cotton yarn from a new spinner because its strength CV% (coefficient of variation) was 12%, above our 8% threshold. This upfront rejection saved a European children's wear brand from potential fabric tearing issues later. For brands wanting to understand yarn quality parameters, the ASTM International standards (like D2256 for tensile strength) are the global benchmark.

Why Is a Comprehensive Tech Pack Non-Negotiable?

A detailed tech pack is your blueprint and our instruction manual. We mandate that it includes, at minimum:

- Physical Swatch of the target hand feel and appearance.

- Full Specification Sheet (composition, weight, width, construction).

- Testing Standards & Tolerances (AATCC, ISO, or specific brand standards).

- Packaging & Labeling Requirements (roll length, inner/outer packing, content labels).

Without this, quality is subjective. With it, quality is measurable. We often help clients, especially startups, build robust tech packs. This upfront investment in clarity prevents 80% of future disputes. Resources like the "Tech Pack Toolkit" from the Fashion Business Incubator provide excellent starting frameworks.

How Does Real-Time Monitoring Work on the Production Floor?

Once production begins, our second shield—Real-Time Monitoring—activates. Because we control our own large-scale weaving factory and have deep partnerships with dyeing and finishing units, our QC teams are physically present on the floor, not waiting for finished goods.

During Weaving/Knitting: Our technicians perform "Loom-State" or "Greige Goods" checks every 4 hours. They're not just looking for obvious stops; they use portable fabric inspection mirrors and LED lights to check for:

- Weaving Defects: Mis-picks, loose ends, oil stains.

- Density & Width: Using calipers and measuring scales to ensure the un-dyed fabric meets the construction spec.

For a complex jacquard order for a French lingerie brand, this real-time check caught a pattern misalignment caused by a faulty electronic card just 30 minutes into the run. The loom was stopped, corrected, and only 15 meters of fabric were lost, compared to potentially 500 meters if caught later.

During Dyeing & Finishing: This is where color and hand feel are born. Our stationed QC staff:

- Monitor Dye Bath Parameters: Temperature, pH, and cycle time are logged digitally.

- Check "First-Lot" Samples: The first 50 meters out of the dyeing machine are dried and tested for color match (using a Datacolor spectrophotometer) and hand feel before the full batch proceeds.

- Audit Finishing Processes: For a water-repellent finish, we verify the chemical concentration and curing temperature in real-time.

What Technology Enables This Level of In-Process Control?

We've moved beyond clipboards. Our system integrates:

- IoT Sensors on critical machinery (like stenters for heat-setting) that stream temperature and speed data to a central dashboard. If a parameter drifts, an alert is sent.

- Mobile QC Apps: Inspectors upload photos and defect logs directly from the factory floor into our cloud-based system, tagging them with the specific machine and batch number.

- Barcode Tracking: Every batch of grey fabric gets a unique barcode. As it moves through dyeing and finishing, each process scans the code, creating a digital production history. This is the backbone of our traceability.

This isn't science fiction; it's operational reality in modern Keqiao mills. For an inside look at how technology is transforming textile QC, industry publications like Textile World often feature case studies on smart factory implementation.

How Do You Handle Quality Discrepancies Mid-Production?

The protocol is strict and immediate. If an in-process check fails:

- Production is halted on that specific batch or machine.

- The QC manager, production head, and account manager are notified within 15 minutes.

- Root Cause Analysis (RCA) begins. Is it a yarn issue? A machine calibration error? A chemical mix problem?

- Corrective Action is taken and verified before production resumes.

- The affected material is isolated and marked for downgrade or repair.

This process was tested in November 2023 during a bulk run of organic cotton sateen. The in-process check detected a slight shade variation. Production was stopped. The RCA found a minor fluctuation in the steam pressure during pre-treatment. The parameter was corrected, and the dyed fabric from the affected batch was separated and offered to the client as a "second quality" at a discount for a different, less color-critical use. Transparency and swift action maintained trust.

What Does the "360° Inspection" Entail Before Shipment?

The third shield is our final, comprehensive barrier. When the fabric is finished, packed, and ready for shipment, it undergoes our "360° Inspection." This is not a random spot check; it's a systematic, full-audit of the order.

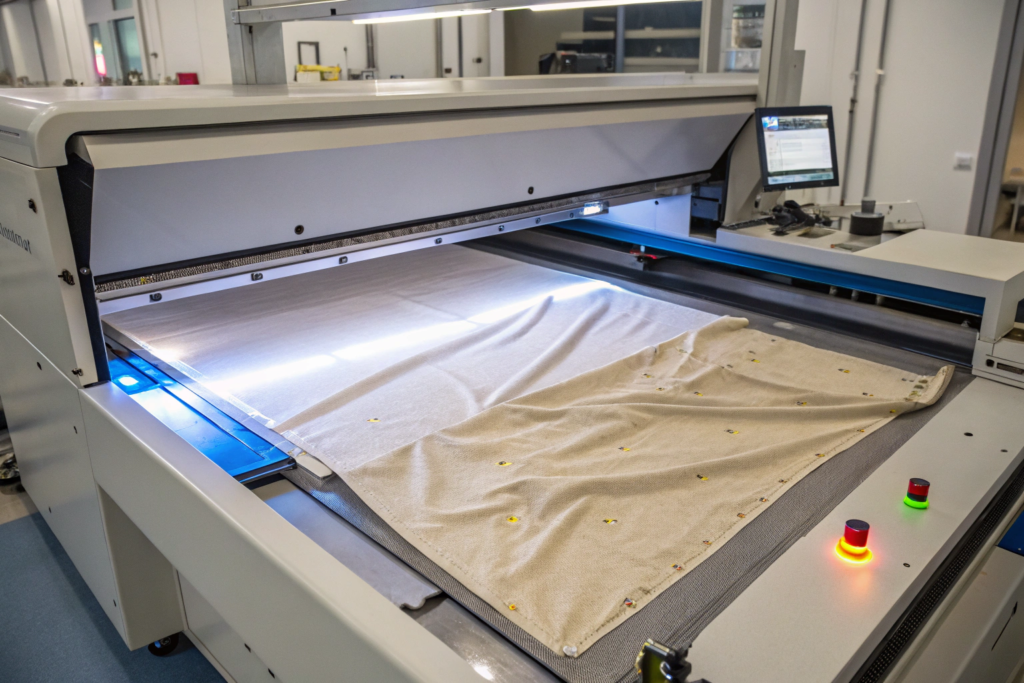

The process takes place in our dedicated, well-lit inspection facility. We use standardized inspection machines (like the Mahlo or similar) that run the fabric at a controlled speed under consistent D65 lighting. Our inspectors, certified to the "4-Point System" as per the ASTM D5430 standard, grade every meter of fabric.

What We Check & Measure:

- Defects: Every flaw (hole, stain, mis-weave) is marked and graded. The total penalty points per 100 square yards must fall below the AQL (Acceptable Quality Level) agreed with the client—typically AQL 2.5 for major defects and 4.0 for minor defects.

- Color Consistency: We compare multiple rolls from different dyeing batches using the spectrophotometer to ensure shade banding is within the agreed DE tolerance.

- Physical Dimensions: We check width (+/- 1cm tolerance) and length of every roll.

- Weight (GSM): We cut and weigh samples from the beginning, middle, and end of multiple rolls.

- Hand Feel & Appearance: Final comparison against the Golden Sample.

Can Clients Participate in or Witness the Final Inspection?

Absolutely, and we encourage it. We offer three options:

- Virtual Live Inspection: We stream the inspection process via video call, showing you defects as they are found and the measurement readings in real-time.

- Third-Party Inspection: We fully facilitate and pay for an inspection by SGS, BV, or Intertek if the client requests it. We are confident in our process.

- Client's Own QC On-Site: Clients are welcome to send their own QC staff to our facility to audit the process and the goods.

In March 2024, a German outerwear brand's QC manager flew to Keqiao to witness the final inspection of their 15,000-meter order of functional nylon. They observed the entire process, conducted their own spot checks, and signed the inspection report on-site. This level of openness is a cornerstone of our partnership model.

What Happens If Fabric Fails the Final Inspection?

Our policy is clear: Non-conforming fabric does not ship. If a roll or batch fails to meet the locked specifications, we have a tiered response:

- Minor Defects within AQL: We grade it as "First Quality" and ship.

- Defects Exceeding AQL / Major Spec Failure: The fabric is quarantined. We immediately inform the client with photos and data. Options are then discussed:

- Replacement: We prioritize production to replace the quantity (if time allows).

- Sorting & Repair: If applicable, we sort out defective pieces and repair minor flaws.

- Commercial Allowance: We offer a significant price discount for the client to use the fabric in a less critical application.

The goal is never to hide or argue, but to solve the problem collaboratively with full transparency.

How Does Digital Traceability Provide Long-Term Quality Assurance?

The fourth shield extends beyond delivery. Our Digital Traceability system ensures every bulk order has a lifelong quality passport. Upon shipment, we generate a unique QR code for the order.

When scanned, this code provides access to a secure digital dossier containing:

- All Test Reports: From our CNAS-accredited lab or third-party labs (SGS/ITS).

- Production Batch Records: Dyeing lot numbers, finishing parameters.

- Inspection Reports & Defect Maps.

- Photographs of packed cartons and the container loading.

This isn't just for your records. It's a powerful tool for future troubleshooting and continuous improvement. For example, if a client encounters an issue during garment manufacturing (e.g., needle cutting), they can reference the exact fabric composition and finish details to diagnose the problem. We used this system in 2023 to help a US client trace a sporadic shrinkage issue back to a specific finishing batch, allowing us to adjust our process and prevent a recurrence in their next order.

How Does This System Integrate with a Client's Supply Chain?

We provide data in formats that integrate with modern PLM (Product Lifecycle Management) systems. The digital dossier can be downloaded or accessed via a secure link, providing a single source of truth for your design, production, and compliance teams.

This traceability is also crucial for sustainability claims. For GRS or GOTS fabrics, the digital trail provides the auditable chain of custody that brands need to support their marketing claims. Understanding the importance of this, organizations like the Sustainable Apparel Coalition are driving industry-wide adoption of digital traceability tools.

What is Fumao's Commitment to Continuous Improvement?

Our QC system is a living process. Every defect, every client feedback, and every test result is logged in our system. Quarterly, our quality committee analyzes this data to identify trends:

- Are certain defect types recurring on a specific loom type?

- Is a particular dye shade giving us consistent challenges?

This data-driven approach leads to machine upgrades, process refinements, and technician re-training. It’s why our client pass rate has climbed from 95% to 98% over the past three years. We don't just fix problems; we engineer them out of the system.

Conclusion

Ensuring quality for bulk fabric orders is not a single inspection; it is a culture of precision embedded across an integrated supply chain. At Fumao Fabric, our "Four Shield" system—Spanning Pre-Production Lockdown, Real-Time Monitoring, 360° Inspection, and Digital Traceability—creates multiple layers of defense against defects, transforming quality control from a cost center into a core competitive advantage that delivers reliability, transparency, and peace of mind.

This systematic approach is what allows us to stand behind our fabrics with confidence and offer the seamless experience that global brands require. It turns the complex, risky endeavor of overseas bulk sourcing into a predictable, partnership-driven process. When you choose Fumao, you're not just buying fabric; you're investing in a system designed to protect your investment at every single step.

If you are looking for a fabric supplier where quality control is a guaranteed process, not a promised afterthought, we invite you to experience the Fumao difference. Let us show you how our integrated manufacturing and rigorous protocols can secure the foundation of your next collection. Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss your next bulk order. We will provide a detailed QC plan tailored to your specific fabric, because your quality is our reputation.