The Minimum Order Quantity (MOQ) is the gatekeeper that stands between your design vision and reality. You find the perfect supplier with stunning fabrics, then you see "MOQ: 3000 meters per color" – and your heart sinks. For startups, small brands, and even larger companies testing new lines, high MOQs can feel like an insurmountable barrier, forcing compromises on design, budget, or quality. This single number often dictates whether a project is viable.

There is no single universal MOQ for custom fabrics from China. The minimum order quantity is a dynamic calculation, typically ranging from as low as 500 meters for basic modifications (like color or simple weave on existing looms) to 10,000 meters or more for fully custom developments (new fiber blends, intricate jacquards, or complex functional finishes). The final number is a negotiation based on four key pillars: the complexity of your design, the type of fiber and yarn, the production stage where customization occurs, and your willingness to share cost burdens. Understanding these levers allows you to strategically influence the MOQ to fit your business.

Let's demystify the factory's logic behind MOQs. This isn't just about them being difficult; it's about physics, chemistry, and economics. We'll break down exactly what you're paying for in that minimum meterage and show you practical strategies to secure workable quantities without sacrificing your vision or your budget.

How Do Yarn and Fiber Choices Drastically Affect MOQ?

This is the first and most fundamental lever. The MOQ starts not at the weaving machine, but at the spinning mill. Standard, readily available yarns (like conventional 30s combed cotton or 75D polyester) are produced in massive quantities for the open market. A factory can purchase these in small lots, which keeps your fabric MOQ low. However, the moment you specify a custom yarn – a unique thickness, a special blend, an eco-certified fiber, or a proprietary filament – you trigger a chain reaction.

The yarn supplier now has a minimum production run, often measured in tons, not kilograms. That cost and volume get passed to the fabric mill. For example, in early 2024, a Danish minimalist brand wanted a fabric using a traceable, GOTS-certified organic cotton blended with 15% recycled cashmere from post-factory waste. The recycled cashmere yarn alone had a minimum batch size of 500kg. This translated to a fabric MOQ of approximately 8,000 meters, which was non-negotiable at the yarn stage. In contrast, choosing a stock organic cotton yarn could have brought the MOQ down to 1,500 meters.

Can I Use Existing Yarns to Create a "Custom" Fabric?

Absolutely, and this is the smartest way to reduce MOQ. This is where working with a supplier with a vast existing yarn library pays off. At Shanghai Fumao, we maintain partnerships with top spinners and keep an extensive inventory of certified and standard yarns. The question to ask is: "Can my design be achieved by creatively using your existing yarn portfolio?"

Instead of developing a new yarn from scratch, consider:

- Twisting: Plying two existing yarns together for a new texture.

- Dyeing: Using space-dyeing or yarn-dyeing techniques on standard yarns for unique color effects.

- Weave Innovation: Applying a novel weave structure (like a custom jacquard or dobby) to a standard yarn set.

A client from California saved their low-volume, high-margin scarf line by using this approach. They wanted a unique heathered effect. Instead of custom-spinning a mélange yarn (high MOQ), we achieved an almost identical result by yarn-dyeing two shades of our existing Tencel™ yarn and plying them, cutting their MOQ from 5,000m to 800m.

What's the MOQ Reality for Sustainable/Functional Fibers?

This is a double-edged sword. Common eco-fibers like standard GOTS organic cotton or base Tencel™ are now commoditized; their MOQs are similar to conventional fibers. However, next-generation sustainable or functional materials often have high MOQs. Fabrics with phase-change materials, certified recycled wool, or specific antiviral coatings require specialty yarns or finishing chemicals produced in large batches.

The rule of thumb: if the special property is added as a finish (e.g., a PU coating for waterproofing), the MOQ is based on the base fabric and the minimum batch size of the chemical bath. If the property is inherent to the yarn (e.g., seaweed fiber), the MOQ is set by the spinner. Always ask your supplier to identify which stage drives the MOQ. Forums like The Sustainable Fashion Forum's resource library often discuss MOQ challenges for new materials.

Does Weave Complexity and Dye Technique Determine MOQ?

Once yarn is secured, the production machinery sets the next MOQ threshold. A plain weave on a standard rapier loom has low setup costs and can run efficiently in shorter lengths. Complexity escalates MOQ in two ways: machine setup time and production waste during setup.

A custom jacquard is the prime example. Designing the digital pattern card and setting up the electronic jacquard machine (or tying the cords on a mechanical one) can take a highly skilled technician 2-3 days. The factory can't absorb that cost over 1,000 meters; they need a 5,000-10,000 meter run to amortize it. Furthermore, the "strike-off" period—where the loom is adjusted for perfect tension and pattern alignment—can waste 50-100 meters of fabric. This waste is part of your MOQ cost.

How Do Sampling and Strike-Offs Work into the MOQ Cost?

Think of your MOQ as covering two things: the goods you receive and the cost of getting the machine ready to produce those goods. The sampling process is your quality checkpoint, but it's not free. A responsible factory will produce lab dips (for color), hand looms (for small weave samples), and strike-offs (first runs on the production loom) before bulk.

A clear factory will break down these costs. For a recent project with a UK activewear brand for a custom elastic satin, the cost structure was:

- Lab Dips & Hand Loom Sample: $300 (flat fee)

- Strike-Off on Production Loom: 80 meters of fabric (charged at cost)

- Bulk MOQ: 2,200 meters (to cover loom setup and efficient run)

The 80-meter strike-off was essentially the first part of the MOQ, used to confirm quality. Understanding this breakdown prevents the sticker shock of a seemingly high MOQ. Resources like "From Design to Delivery" on the Fashion Incubator blog offer great insights into these hidden production costs.

Are Print and Embroidery MOQs More Flexible?

Often, yes, because the customization happens later in the process, on an already-woven base cloth (grey fabric). This separates the MOQ for the base fabric (which can be a standard, low-MOQ item) from the MOQ for the custom application.

- Digital Printing: MOQs can be very low, sometimes 100 meters or even less per design, as there are no physical screens to engrave. The cost is in the digital file setup and the printer calibration.

- Rotary Screen Printing: Requires metal screens per color. MOQs are higher (often 1,000m+ per design) to justify the screen-making cost (~$150-$300 per screen).

- Embroidery: MOQs depend on the complexity and the number of needle heads required. Simple logos can have MOQs of just a few hundred pieces, while complex all-over embroidery may require 1,000m+.

The key is to source the base fabric and the printing/embroidery from a coordinated supplier. At Shanghai Fumao, because we control the weaving and have partnered printing units, we can often bundle the base fabric MOQ across multiple print designs for a client, giving them the economy of scale on the grey good and flexibility on the print.

Can I Negotiate a Lower MOQ Without Sacrificing Quality?

Negotiation is always possible, but it's a trade-off, not a discount. You're not haggling over the price per meter; you're restructuring the cost recovery model. Presenting yourself as a strategic partner, not just a one-time buyer, opens doors.

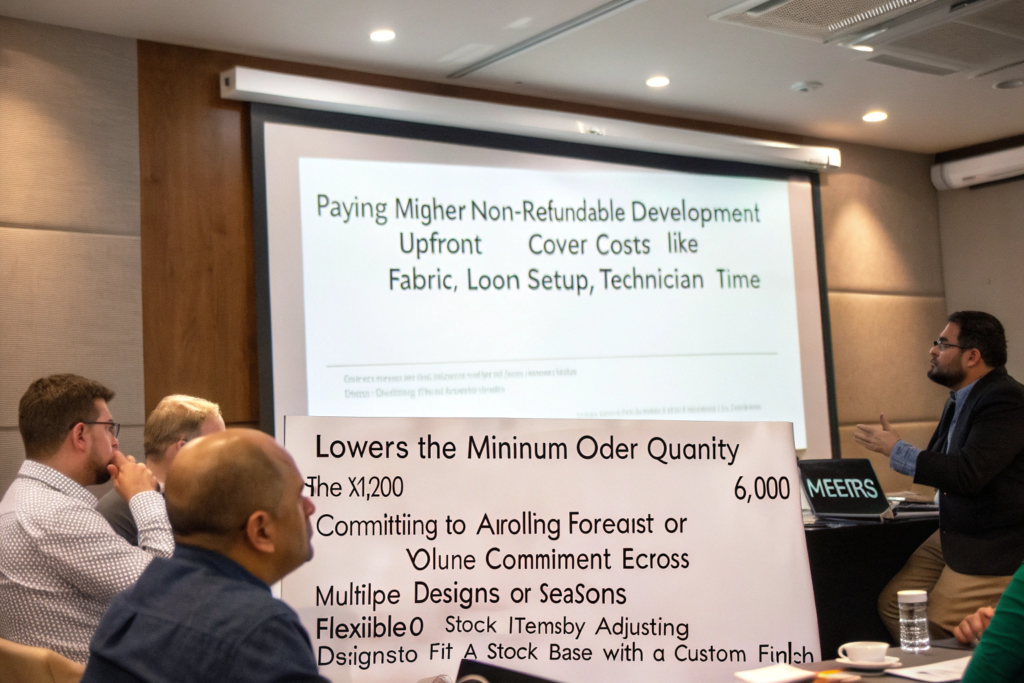

Factories fear low MOQs because of disproportionate fixed costs. Your goal is to reduce their risk and increase their long-term incentive. Here are proven strategies:

- Share the Setup Cost: Propose paying a higher, non-refundable development fee upfront to cover strike-off fabric, loom setup, and technician time. This reduces the financial risk for the factory, allowing them to lower the meterage MOQ. We did this with an emerging New York designer in 2023; they paid a $1,200 NRE (Non-Recurring Engineering) fee, which lowered their jacquard fabric MOQ from 6,000m to 2,500m.

- Commit to a Volume Over Time: Offer a rolling forecast or an annual volume commitment across multiple designs or seasons. This guarantees the factory future business, making them more flexible on the initial order. Sign a memorandum of understanding.

- Be Flexible on Stock Items: Ask if your design can be adjusted to fit a "stock base" with a custom finish. For example, use a stock 240GSM cotton interlock and apply your custom enzyme wash. The MOQ is then for the finishing bath, not the fabric weaving.

What Are the Risks of an Exceptionally Low MOQ?

If a supplier agrees to an MOQ that seems too good to be true, be cautious. The risks include:

- Quality Sacrifice: They may run your order as a "tag-on" at the end of another client's run, leading to potential color contamination or lax quality checks.

- Hidden Costs: The per-meter price may be exorbitantly high, negating any benefit.

- Supplier Instability: They might be desperate for cash flow, which is not a sign of a healthy long-term partner.

The safest path is to work with suppliers like us at Shanghai Fumao who have explicit small-batch production lines or divisions. These lines are optimized for shorter runs, with faster setup procedures and calibrated cost models. You're not getting an exception; you're using a service built for your needs.

How Do Payment Terms Influence MOQ Negotiation?

Cash is king. Offering favorable payment terms can be a powerful negotiating tool. Instead of the standard 30% deposit, 70% before shipment, consider:

- 40% or 50% Deposit: This gives the factory more working capital to purchase your custom yarns.

- 100% TT Upfront for the First Order: This eliminates all credit risk for the supplier, making them much more likely to accept a lower MOQ for a trial order.

Always use a secure payment method like bank transfer with clear contracts. Never compromise on secure payment for a lower MOQ. Platforms like Alibaba's Trade Assurance can provide a layer of security, but understand its terms and limits.

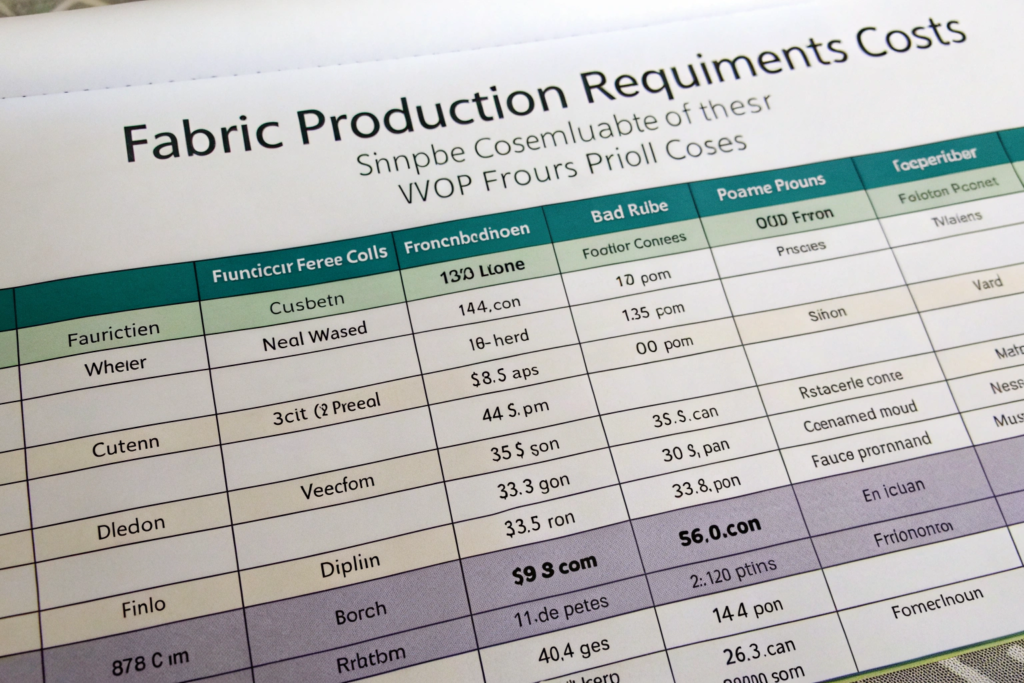

What Are Realistic MOQ Expectations for Different Fabric Types?

Let's translate theory into numbers. The table below provides a realistic range based on Keqiao market dynamics in 2024, assuming a new client relationship with no long-term commitment. These are starting points for negotiation.

| Fabric Customization Type | Typical MOQ Range (Meters) | Primary Cost Driver | Strategy for Lower MOQ |

|---|---|---|---|

| Color Change Only (on existing base fabric) | 500 - 1,500 m | Minimum dye bath capacity; lab dip costs. | Use stock base fabric; combine colors across seasons. |

| Simple Custom Weave (Dobby, basic texture) | 1,000 - 3,000 m | Loom setup time; warp tying-in. | Use existing yarns; agree to share setup cost (NRE). |

| Custom Jacquard | 3,000 - 10,000+ m | Jacquard machine/patterning setup; technical labor. | Simplify design; explore digital print on plain cloth. |

| New Fiber Blend (Yarn Development) | 5,000 - 20,000+ m | Spinner's minimum batch size (in kg/ton). | Modify design to use existing specialty yarns. |

| Functional Finish (e.g., waterproof, FR) | 2,000 - 5,000 m | Chemical batch minimums; finishing line setup. | Apply finish to a standard fabric you commit to annually. |

| Digital Print (on stock fabric) | 100 - 500 m per design | File setup & printer calibration time. | Group multiple designs for a single production run. |

How Does Supplier Size and Specialty Affect MOQ?

This is crucial. A giant mill supplying Zara may have a 10,000m minimum for any conversation. A smaller, agile factory (like many in our Keqiao network) often competes on flexibility. Their entire operation is tuned for shorter runs and faster turnarounds.

Look for suppliers who advertise "small MOQ" or "fast fashion support." Visit their facility virtually. Do they have smaller, modular production lines? Do they showcase a wide variety of sample fabrics in small quantities? This indicates a business model built for versatility. In our case, our dedicated sampling department and partnerships with niche weaving studios allow us to service clients needing 500m of a special fabric alongside those ordering 50,000m.

What's the Future of MOQs? (AI, On-Demand Manufacturing)

The future points towards even greater flexibility. AI is being used to optimize loom scheduling, allowing factories to slot in smaller custom runs between large orders with less downtime. On-demand digital textile printing is already a reality for sampling and micro-production.

The most promising trend is platformization. Some forward-thinking suppliers are creating digital platforms where multiple brands can aggregate their demand for similar fabric types (e.g., a heavy organic cotton twill), triggering a production run that benefits everyone with lower individual MOQs. While still nascent, following industry analysts on LinkedIn groups focused on textile technology innovation can keep you ahead of these trends.

Conclusion

The Minimum Order Quantity for custom fabrics from China is not a fixed barrier but a variable to be managed. It is the financial expression of the physical and technical effort required to bring your unique textile to life. By understanding that the MOQ is built layer by layer—from yarn spinning to weaving setup to finishing—you gain the power to influence it. Strategic choices in fiber selection, openness to creative technical solutions, and a partnership-based approach to sharing costs and forecasts can unlock surprisingly accessible minimums.

The goal is not to find the supplier with the absolute lowest number, but the one whose business model aligns with your volume and who offers transparent cost breakdowns. A reliable partner will work with you to explore every option, from modifying designs to fit existing capabilities to structuring fair NRE fees, ensuring your project is feasible without compromising on the quality or innovation that defines your brand.

If you're navigating the complexities of MOQ for an upcoming collection and need a partner who values transparency and creative problem-solving, we should talk. At Shanghai Fumao, our integrated supply chain in Keqiao is built for both scale and agility. We take pride in helping brands of all sizes materialize their fabric visions. Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss your specific project. Let's analyze your design and find the most efficient path to production, together.