If you're sourcing lace for your next collection, you've probably been hit with quotes that make your head spin. One supplier quotes $2 per meter, another asks for $20, and you're left wondering: what exactly am I paying for? The price gap isn't just random; it's a direct reflection of the lace's grade, which encompasses everything from the fiber origin to the complexity of its construction. Understanding this breakdown is the difference between accidentally blowing your budget on a sample run and strategically investing in a fabric that elevates your brand.

The price range for lace fabric varies dramatically, from as low as $1.5 to $3 per meter for basic synthetic mass-produced lace to $50 to over $200 per meter for haute couture laces made with precious fibers and intricate handwork. This range is determined by a matrix of factors: the fiber content (polyester vs. silk), the production method (Raschel warp knit vs. Leavers lace), the complexity of the pattern, the width, and any special finishes. As a fabric supplier rooted in Keqiao, I can tell you that most commercial fashion brands operate in the $5 to $25 per meter range, where quality and cost find a practical balance.

But throwing around price brackets alone won't help you make a smart buying decision. You need to know what you're getting at each level and, more importantly, how to align that with your product's market positioning. Let's peel back the layers of the lace industry and decode the cost drivers, so you can confidently negotiate and specify exactly what you need for your line.

What are the different types of lace and how do they impact price?

Lace isn't just one thing. The manufacturing technique is the single biggest dictator of its character and cost. Think of it like cars: a compact sedan and a hand-assembled sports car both get you from A to B, but the engineering, time, and materials involved are worlds apart.

The two primary methods are Raschel Knitting and Leavers Lace. Raschel is the workhorse of the modern lace industry. It's produced on high-speed electronic warp knitting machines. It's efficient, versatile, and perfect for continuous all-over patterns like those used in lingerie or stretch lace trims. Because of its speed and automation, Raschel lace sits at the more affordable end of the spectrum. For a deep dive into how modern Raschel machines create complex patterns, resources like Textile School offer excellent technical breakdowns. On the other hand, Leavers Lace (or ‘Leavers’ for short) is the gold standard. Originating in Nottingham, this method uses a legacy loom where each thread is individually controlled. The process is incredibly slow and produces narrower widths, but the result is lace with unparalleled delicacy, detail, and a distinct ‘scalloped’ edge. This method commands a premium price.

Beyond the base construction, other types further segment the market. Chemical Lace (or Embroidered Lace) starts as an embroidered pattern on a soluble fabric base, which is then washed away, leaving only the embroidered threads. It allows for incredible detail and is often used for appliqués. Crochet and Bobbin Laces are primarily handmade or semi-handmade, placing them at the very top of the price pyramid. They are almost exclusively used in luxury couture. When you’re evaluating how to choose between Raschel and Leavers lace for your design, you’re fundamentally making a cost-versus-aesthetic decision early in your development process.

How does fiber content drive the base cost of lace?

The thread used is the literal foundation of the fabric. Synthetic fibers like polyester and nylon are the most common, especially in Raschel laces. They are inexpensive, durable, and can be engineered to have good stretch and sheen. A basic 100% polyester lace can start as low as $1.5/m. However, the quality of the polyester yarn matters greatly; finer, softer filaments cost more. Then we have natural fibers. Cotton lace brings a matte, breathable, and classic feel. It’s more expensive than polyester but offers a natural aesthetic for children's wear or vintage-style garments. Silk lace is the pinnacle. Whether it's cultivated silk or wild silk (Tussah), it provides a sublime luster, drape, and hand-feel that synthetics cannot replicate. It is often paired with the Leavers or handmade techniques, creating the most expensive category. Metallic yarns (usually a polyester core wrapped in metalized film) or the inclusion of sustainable fibers like GOTS certified organic cotton also add to the cost. A blended lace, like a polyester-cotton mix, aims to balance cost with some natural fiber benefits.

What role do design complexity and production scale play?

This is where the “art” meets the “manufacturing.” A simple, small repeating geometric pattern (a dot grid, for example) is fast to produce and wastes minimal material. A large, elaborate, non-repeating floral pattern with intricate vines and leaves requires significant machine programming (for Raschel) or setup (for Leavers), and often results in more ‘fall-off’ or waste material between motifs, which you are effectively paying for. (Here I have to interject—we once developed a complex custom lace for a French lingerie brand, and the sampling alone took three rounds just to perfect the motif alignment and reduce waste). Furthermore, customization has a huge cost impact. Using a supplier’s existing ‘stock’ lace design is the most economical path. Modifying an existing design (changing the scale, adding a motif) incurs development fees. A completely custom design from scratch requires creating new digital files or Leavers cards, which is a significant R&D investment amortized over your order quantity. This is why understanding minimum order quantities for custom lace fabric is critical for budgeting; a higher MOQ spreads that initial cost over more meters, lowering the per-meter price.

How much should I budget for lace in my product category?

Your end use dictates the necessary grade and, therefore, the budget. Let's break it down by market segment with some real-world price brackets we see daily at Shanghai Fumao.

| Product Category | Typical Lace Type | Key Price Drivers | Realistic Price Range (Per Meter) | Best For |

|---|---|---|---|---|

| Fast Fashion / Volume Apparel | Raschel, Polyester/Nylon | Speed, low material cost, large MOQs | $1.5 - $8 | High-turnover items where trend > longevity |

| Lingerie & Swimwear | Raschel (often with Spandex), Embroidered | Stretch recovery, softness, dye-fastness | $5 - $15 | Comfort and fit-critical garments |

| Bridal & Evening Wear | Leavers, Silk blends, Chantilly lace | Fiber luxury, pattern artistry, hand-feel | $20 - $100+ | Hero pieces where detail is the selling point |

| Children's Wear | Cotton or soft Polyester Raschel | Safety, non-irritating, Oeko-Tex certification | $4 - $10 | Gentle fabrics meeting strict compliance |

| Home Décor (Curtains, etc.) | Wide-width Raschel, chemical lace | Durability, light filtration, width | $8 - $20 (depends heavily on width) | Decorative textiles requiring structure |

For example, in early 2023, we worked with an emerging Los Angeles-based swimwear brand. They needed a chlorine-resistant nylon lace with 30% spandex for a one-piece suit. They initially sourced a $4/m lace from a non-specialized vendor, but the color faded after light exposure and the recovery was poor. We developed a comparable but higher-quality version at $7/m. The cost increased, but their return rate dropped by 15%, and they secured a premium stockist because of the perceived quality. The budget wasn't about finding the cheapest option, but the most cost-effective for their market.

How do finishes and certifications add to the final cost?

The lace that comes off the loom is rarely the final product. Dyeing and finishing processes add layers of cost and value. Standard piece-dyeing is cost-effective. But if you require yarn-dyed lace (where the threads are dyed before weaving), you get superior color fastness and a heather-like depth—for a 20-40% premium. Special finishes like enzyme washing for a super soft peach-skin hand feel, waterproofing, or anti-bacterial treatments all add per-meter charges. Then come the certifications. An Oeko-Tex Standard 100 certification, which tests for harmful substances, is almost standard now for reputable suppliers and adds a marginal cost. However, more rigorous certifications like GOTS (Global Organic Textile Standard) for organic fibers or specific Reach compliance documentation for the EU market involve stringent supply chain audits and testing, significantly impacting the price. You're paying for trust and market access.

Why do sampling and MOQs create such a price hurdle for small brands?

This is the perennial pain point. The development cost for a custom lace is fixed. Whether you order 100 meters or 10,000 meters, the cost of creating the design file, setting up the machine (or leasing Leavers cards), and producing the first sample run remains the same. For a large brand with a 10,000m order, that development cost might add only $0.50 per meter. For a small brand ordering 500m, it could add $10 per meter, making the fabric untenable. This is why we at Shanghai Fumao have invested in agile sampling. Our digital design system allows us to produce a first visual prototype within 48 hours at a low cost, and we work with clients to simplify designs for production efficiency. We often advise startups to explore our vast stock lace library first—modifying a stock design can cut development lead time and cost by over 60%.

What are the hidden costs beyond the price per meter?

The quoted FOB price per meter is just the starting line. Ignoring the ancillary costs is where budgets truly derail. The first is width and yield. Lace is often sold by the meter, but you buy it by the width (e.g., 150cm). A wider lace may have a higher per-meter price, but if your pattern pieces are small, you might get more pieces out of that width compared to a narrower lace, improving your overall yield and effectively lowering your cost-per-garment. You must calculate fabric utilization. Then there's managing shipping and tariffs for textile imports from Asia. During peak seasons (March-May, Aug-Oct), freight costs can double, and delays at port can stall your entire production. Planning for lace production must account for these logistics windows. A European client of ours now finalizes their pre-production for autumn collections by December, ensuring lace production is done before the Chinese New Year shutdown, avoiding the post-holiday congestion and 15-20% higher shipping rates.

How do quality failures turn a ‘cheap’ lace into an expensive mistake?

A low price tag is meaningless if the fabric fails. Common and costly failures include:

- Poor Colorfastness: The lace bleeds in the wash or changes color under store lighting. We test for this rigorously in our CNAS lab.

- Inconsistent Stretch: In stretch laces, uneven recovery causes garment distortion.

- Shrinkage: Lace that shrinks beyond the agreed tolerance (usually 3-5%) will ruin assembled garments.

- Snagging and Low Strength: Delicate-looking lace still needs mechanical strength. A snag during sewing or wear renders the item useless.

In 2022, a UK fast-fashion retailer faced a nightmare: a $3/m polyester lace they sourced elsewhere shrunk by 8% after the first industrial wash, causing $200,000 in finished goods to be scrapped. The ‘savings’ on fabric were wiped out a hundred times over. Our quality control protocol includes pre-shipment bulk testing and provides a QR code tracking system for each batch, giving you direct access to the test reports for composition, shrinkage, and colorfastness. This transparency is part of the value, not just the commodity price.

Why is supplier expertise a critical part of the cost equation?

You’re not just buying fabric; you’re buying a supplier’s problem-solving ability. An experienced lace specialist will guide you on design-for-manufacturability, suggest alternative constructions to hit a price point, and foresee production issues. For instance, a New York designer wanted a sheer lace with a specific motif for a spring 2024 collection. The initial Leavers quote was prohibitive. Our team suggested a high-fidelity Raschel embroidery technique that mimicked the look at 40% of the cost and a 4-week shorter lead time. The designer hit their margin and delivery target. This consultative partnership, which we foster at Shanghai Fumao, prevents expensive mistakes and optimizes your total cost of ownership. A less experienced trader might just take the order and deliver a subpar product, costing you more in the long run.

How can I negotiate better lace fabric prices without sacrificing quality?

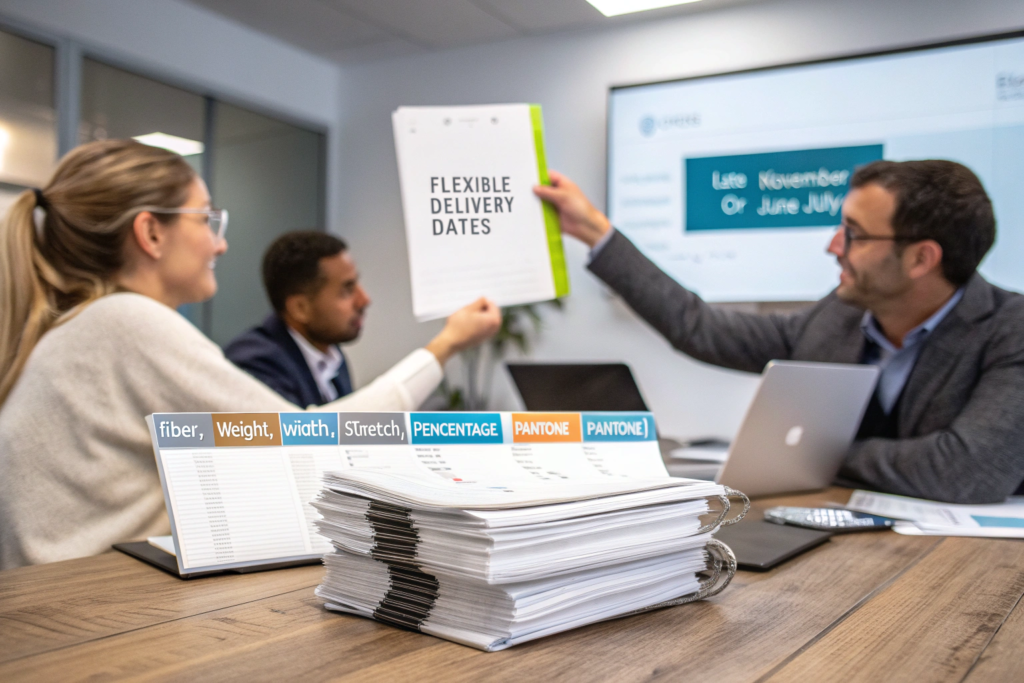

Negotiation isn’t just about haggling over a number. It’s about structuring the deal intelligently. First, provide crystal-clear tech packs. The more precise your specifications on fiber, weight, width, stretch percentage, and color standard (Pantone), the less room for error and costly revisions. Second, be flexible on delivery timing. If you can schedule production during a traditionally slower period for the factory (like late November or June-July), they may offer a discount to keep their lines running. Third, consolidate your sourcing. If you’re buying lace, lining, and main fabric from the same supplier, you have significantly more leverage. We often give bundled pricing advantages to clients who use our full package, from yarn to shipping. Finally, build a relationship. We prioritize and offer better terms to clients we work with season after season. It reduces our customer acquisition cost and allows for more collaborative planning.

What questions should I ask to decode a lace fabric quote?

Never look at just the bottom line. Interrogate the quote:

- "Is this price for stock design or custom?" This is the most fundamental question.

- "What is the exact fiber composition and yarn count?" 85% polyester/15% spandex is different from 92%/8%, and the yarn denier affects hand and price.

- "Does the price include sampling, and how many rounds?" Know what development support is included.

- "What are the payment terms?" 30% deposit is standard, but for established relationships, we can sometimes offer more flexible terms.

- "What certifications are included, and are test reports provided?" Ensure the quoted price includes the compliance you need.

Asking these questions shows you’re a professional buyer and helps avoid nasty surprises. For a comprehensive checklist, many industry professionals share templates on forums like Fashion-Incubator.

When is it worth paying a premium for a higher-grade lace?

The answer lies in your brand's value proposition. Pay the premium when:

- The Fabric is the Hero: In bridal, evening wear, or luxury lingerie, the lace is the design. Compromising here compromises the entire product.

- You Need Technical Performance: For activewear with lace panels or swimwear, the lace must withstand chlorine, UV, and constant stretch. The premium buys performance integrity.

- You are Building Brand Equity: Using higher-quality, certified sustainable lace (like our BAMSILK or recycled polyester laces) is a tangible story you can market to conscious consumers, allowing for a higher retail price.

- You Require Supply Chain Certainty: A premium supplier like Shanghai Fumao offers reliability, consistent quality, and expert support, reducing the risk of production disasters that can sink a small brand.

Conclusion

Navigating the price range for lace fabric is less about hunting for the lowest number and more about understanding the value chain. From the mechanized efficiency of Raschel to the artisanal legacy of Leavers, from the humble polyester filament to the luxurious silk yarn, each choice adds a layer of cost and capability. Your mission is to match this spectrum to your product’s purpose, your brand’s position, and your customer’s expectations. Remember to factor in the hidden costs of logistics, compliance, and, most critically, the risk of quality failure. A well-chosen lace, even at a higher per-meter cost, becomes an investment in your product's success, customer satisfaction, and brand reputation.

If you’re ready to move beyond generic quotes and develop lace that truly aligns with your vision and budget, let’s have a concrete conversation. Our team specializes in translating design concepts into commercially viable, beautiful fabrics. For a direct consultation on your next project, I encourage you to reach out to our Business Director, Elaine. She can connect you with our lace specialists and guide you through our development process. You can contact her at elaine@fumaoclothing.com. Let's create something exceptional together.