It was a Monday morning in late 2019 when the express package arrived from a boutique in Paris. Inside were three swatches of the same Chantilly lace, dyed "burgundy." One was a deep wine, another leaned purple, and the third had a brownish tint. The note was desperate: "We cannot proceed with production. Which one is correct?" The answer was none—they all failed. This wasn't a design problem; it was a dyeing disaster. The lace, its fiber blend, and the dyeing process were not harmonized. Achieving consistent, vibrant color on lace is one of the most technically demanding tasks in textile production. Unlike flat fabrics, lace is a 3D structure of varying densities, making uniform dye penetration a constant battle. This guide will pull back the curtain on the industrial dyeing process for lace, revealing the precise steps, critical parameters, and supplier questions you must ask to ensure the color in your tech pack is the color that arrives on your production floor.

Dyeing lace fabric to achieve consistent and vibrant colors is a controlled chemical and physical process that depends on three pillars: precise fiber identification, selection of the correct dye class and chemistry, and meticulous process control during pre-treatment, dyeing, and finishing. Consistency is achieved through laboratory-based color formulation and rigorous in-process checks, while vibrancy is a function of dye selection, fabric preparation, and the use of optical brighteners or special finishes. For lace, the added challenge is ensuring the dye penetrates uniformly into both the dense patterned areas and the open mesh ground without distorting the delicate structure.

If you've ever received lace that looks perfect on the roll but turns patchy after sewing, or if colors fade after one wash, the failure happened in the dye house. Understanding this process is your best defense against costly, colorful mistakes.

Why is Dyeing Lace More Challenging Than Dyeing Woven Fabrics?

Lace is a rebel. Its structure defies the uniform rules that govern dyeing for plain knits or wovens. The primary challenge is differential density. A lace fabric has areas of high thread density (the pattern) and very low density (the open mesh). In a dye bath, the dye molecules migrate and absorb at different rates in these zones. If not controlled, this results in barre or shading—the pattern may dye darker or lighter than the ground, creating a visible, unintended contrast that ruins the aesthetic.

Secondly, lace is often made from fiber blends to achieve specific properties. A common stretch lace might be 85% Nylon (a synthetic) and 15% Spandex (an elastane). Nylon dyes with acid dyes, while Spandex requires specialized disperse dyes. Dyeing a blend requires either a single dye that works on both fibers (rare) or a complex, two-step process with different dyes and chemistries. Get the balance wrong, and the Spandex remains undyed (looking white or grey) or the colors on each fiber component don't match, resulting in a dull, muddy hue.

Finally, lace is mechanically delicate. The agitation in a dyeing machine—essential for uniformity—can cause snagging, pulling, or distortion of the openwork. The choice of dyeing machine (e.g., overflow vs. jet) and the loading method are critical to preserving the fabric's structural integrity. At Shanghai Fumao, we never dye delicate Raschel lace in the same machine or with the same cycle we use for heavy cotton canvas. It's a dedicated process.

What Are the Key Stages in the Lace Dyeing Process?

A controlled dyeing process is a sequence, not a single step. Missing one can compromise everything that follows.

- Pre-treatment (Scouring & Bleaching): This is the most important stage for achieving vibrancy. Raw lace contains natural impurities (oils, waxes) and, if cotton or silk, natural color pigments. Scouring washes these out. For white or bright pastels, bleaching is essential. A poorly pre-treated lace will never dye evenly or brightly; the dye will stick to the impurities instead of the fiber. We consider pre-treatment so critical that we audit our partner dye houses on their water quality and scouring recipes.

- Dye Bath Preparation & Exhaustion: This is where the color is applied. The dye, chemicals, and lace are loaded into the machine. The temperature is ramped up according to a precise time-temperature profile specific to the fiber and dye class. The dyes migrate from the water (the liquor) onto the fibers. The goal is high exhaustion—meaning almost all dye leaves the water and bonds to the fabric. Low exhaustion leads to wash-off issues and effluent problems.

- Fixing & Washing Off: After dyeing, the loose dye molecules that didn't chemically bond must be removed through rigorous rinsing and soaping. This step is what ensures colorfastness to washing and crocking. Skipping proper wash-off is a common shortcut that leads to color bleeding onto skin or other garments.

- Finishing & Drying: Here, softeners, optical brighteners (for extra pop), or water repellents are applied. Drying must be controlled (often using a tensionless dryer) to prevent shrinkage or distortion. The final heat setting for synthetics like polyester or nylon locks the dye in.

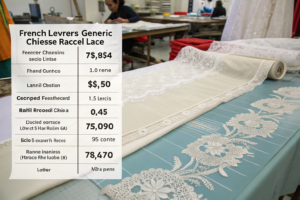

How Does Fiber Content Dictate the Choice of Dye?

The dye must match the fiber's chemical personality. Here’s the essential breakdown:

| Fiber Type | Recommended Dye Class | Key Process Requirement | Risk if Wrong |

|---|---|---|---|

| Polyester | Disperse Dyes | High-temperature dyeing (130°C / 266°F) under pressure. | Poor color yield, sublimation fading. |

| Nylon | Acid Dyes | Careful pH control in the dye bath. | Uneven dyeing, "barre" effects from yarn variations. |

| Cotton | Reactive Dyes | Requires salt and alkali (soda ash) to fix the dye. | Poor wash-fastness, color runs in laundry. |

| Silk | Acid Dyes | Gentle process, lower temperature to preserve luster. | Loss of sheen, fabric damage. |

| Spandex | Special Disperse Dyes | Often dyed simultaneously with nylon (carrier method). | Un-dyed white cores, reduced stretch recovery. |

For blends like Polyester/Cotton lace, a two-bath process using both disperse and reactive dyes is standard. The takeaway: you must know your lace's exact fiber composition percentage before dyeing can even be quoted. An assumption can lead to complete failure.

How Do Professional Dyers Ensure Color Consistency from Lab to Bulk?

The secret weapon is the lab dip. This is not a "rough sample." It's the contractual color target.

- Digital Color Formulation: The dyer uses a spectrophotometer to read your physical color standard (a swatch, Pantone chip, or printed reference). Software then calculates a recipe—precise grams of specific dye stocks per kilogram of fabric.

- Creating the Lab Dip: A small sample (100-200g) of your actual production lace is dyed in a miniature lab machine using this recipe. This sample is then dried and conditioned.

- Approval Under Standard Lights: The lab dip must be approved by you under a light box that simulates multiple light sources: Daylight (D65), Store Lighting (TL84), and Home Lighting (Incandescent A). A color that shifts dramatically under different lights (metamerism) is a recipe for customer returns.

- Bulk Recipe Scaling & Adjustment: Once the lab dip is approved, the recipe is scaled for the bulk order. Crucially, a batch sample from the first bulk dye lot is checked against the approved lab dip before the entire lot proceeds. This two-step approval is non-negotiable.

In 2023, a sportswear brand sent us a digital Pantone for a neon coral trim lace. Our first lab dip matched under daylight but turned dull under store lights. Our lab adjusted the recipe using a specialized guide for dyeing neon and high-visibility colors, adding a fluorescent whitening agent to the mix. The second dip was a perfect match across all light sources, and the bulk order was flawless.

What is a Strike-Off and Why is it Different from a Lab Dip?

This is a crucial distinction often misunderstood:

- Lab Dip: A small sample dyed to match a color standard. It's about the color only, often on a fabric similar to production.

- Strike-Off (or Production Sample): A sample dyed using the final production fabric and the finalized dye recipe from the approved lab dip. It's a full dress rehearsal.

You need both. The lab dip confirms the color formula. The strike-off, which we always insist on at Shanghai Fumao, confirms that the formula works perfectly on the exact lace construction you ordered, revealing any issues related to density or blend. Approving a strike-off is your green light for bulk dyeing.

What Equipment is Used for Dyeing Lace?

The machine must protect the fabric. The two most common types for delicate lace are:

- Overflow Dyeing Machine: Gently lifts the fabric with a flow of dye liquor. It's low-tension and ideal for delicate, open structures like lace and mesh. This is our go-to for most lace orders.

- Airflow Dyeing Machine: Uses a jet of air to transport the fabric, using minimal liquor. It's very gentle and reduces water and chemical consumption, making it excellent for both quality and sustainable dyeing practices.

Beware of suppliers using aggressive jet dyeing machines for lace—the high-pressure flow can stretch and damage it.

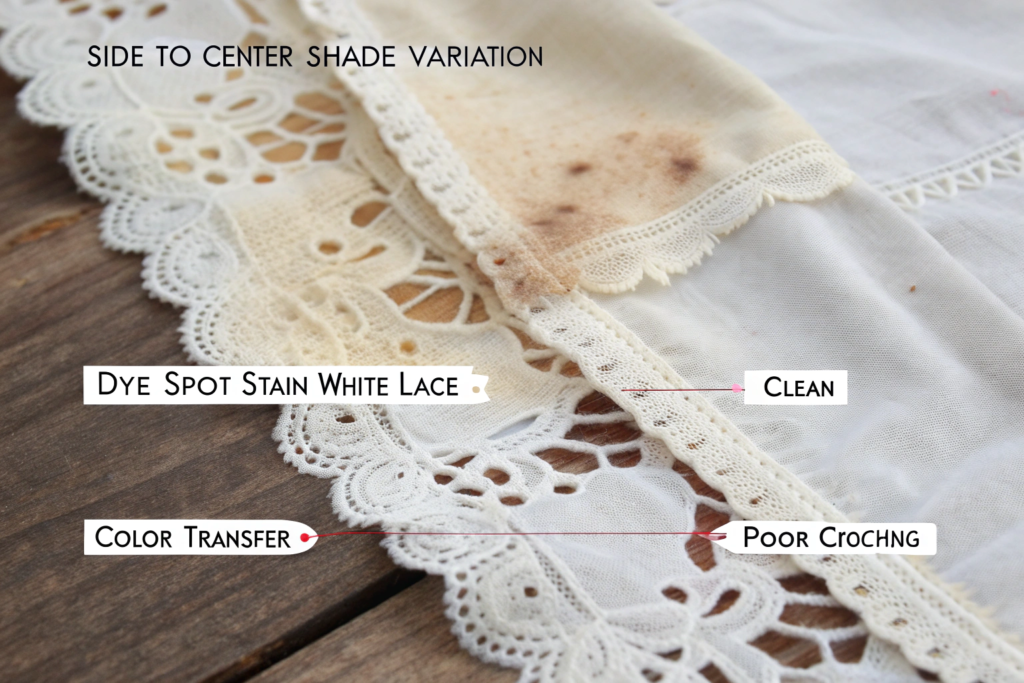

What Are the Most Common Dyeing Defects in Lace and How to Prevent Them?

Knowing the enemy helps you fight it. Here are the top lace dyeing defects:

- Side-to-Center Shading (Listing): The edges of the fabric roll are a different shade than the center. Cause: Uneven dye liquor circulation or improper roll winding. Prevention: Use appropriate dyeing machines and ensure lace is loaded evenly on perforated tubes.

- End-to-End Shading (Tailing): The beginning of the roll dyes differently from the end. Cause: Depletion of dye chemicals over time in the bath. Prevention: Use automated dosing systems and proper cycle design.

- Dye Spots/Stains: Localized dark spots. Cause: Undissolved dye particles or oil stains from machinery. Prevention: Proper dye dissolution and filtration, regular machine maintenance.

- Poor Colorfastness: Color fades or bleeds during washing, rubbing, or light exposure. Cause: Inadequate fixing or wash-off. Prevention: Implement and verify AATCC colorfastness test methods for washing, crocking, and light.

- Fabric Damage: Loss of strength, shrinkage, or distortion. Cause: Overly aggressive chemical treatment, excessive temperature, or mechanical stress. Prevention: Fiber-specific process control and using tensionless dryers.

How Can You Specify Dyeing Quality in Your Purchase Order?

Turn your knowledge into a contract. Your PO should include:

- Fiber Content: Exact percentage (e.g., 92% Polyester, 8% Spandex).

- Color Standard: "Color to match approved lab dip #XXX and physical strike-off sample."

- Light Fastness & Wash Fastness Requirements: e.g., "Colorfastness to washing: AATCC Test Method 61-2A, Grade 4 minimum. Colorfastness to light: AATCC TM16, Grade 5 minimum."

- Testing & Certification: "Supplier to provide test report from accredited lab (e.g., SGS, ITS) for each dye lot confirming fastness and composition."

- Approval Process: "No bulk dyeing to commence without written approval of strike-off from buyer."

What Sustainable Dyeing Options Exist for Lace?

The industry is shifting, and lace is part of the change. Viable options include:

- OEKO-TEX® Certified Dyes: Ensures dyes are free from harmful substances.

- Digital Printing on Lace: For multi-color patterns, this applies color only where needed, reducing water and dye usage by up to 70% compared to piece dyeing. It's ideal for complex, watermark-like effects.

- Water Recycling Systems: Advanced dye houses treat and recycle dye bath water.

- Bio-based or Natural Dyes: While challenging for industrial consistency, they are being developed for niche, high-end markets. The key is to ask your supplier, like Shanghai Fumao, about their investment in low-impact dyeing technologies. It's no longer a niche request but a market expectation.

Conclusion

Dyeing lace to achieve consistent, vibrant colors is a precise science that blends chemistry, physics, and mechanical engineering. Success hinges on understanding the unique challenges of the lace structure, respecting the strict requirements of fiber-specific dye chemistry, and enforcing a rigorous process of lab development and bulk production control. For brands, this means moving beyond simply providing a Pantone number. It means engaging with your supplier as a technical partner, specifying quality requirements contractually, and investing the time in the approval stages that matter—the lab dip and the strike-off.

When done correctly, the result is more than just a color. It's a reliable component of your brand identity, a product that performs for your customer, and a source of confidence rather than crisis. The difference between a good lace and a great one is often literally in the dye.

Are you ready to achieve flawless, consistent color for your next lace collection? Partner with a supplier that controls the process from fiber to finished dye lot. Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss your project. With our integrated network and technical dyeing expertise, we’ll ensure your colors are always on point.