The nightmare is familiar: you’ve sourced a breathtaking, intricate lace sample. It's perfect for your new collection. You send it to production, and the first batch comes back—the pattern is distorted, the repeat is off by a few millimeters, and the delicate flowers look blurry. What went wrong? Nine times out of ten, the failure point is in the digitization process. I learned this the hard way over a decade ago when a major order for a French lingerie brand was rejected because the lace motifs didn’t align perfectly at the seams. The physical sample was beautiful, but the digital file guiding the Raschel machines was flawed. This article will demystify the critical step of digitizing lace patterns, transforming your delicate design from a beautiful idea into a flawlessly repeatable, production-ready reality.

Digitizing a lace pattern is the process of converting a visual design into a digital instruction file (like a DST or AI file) that precisely controls the movements of industrial knitting or embroidery machines, such as Raschel machines. This digital blueprint dictates every loop, hole, and connection point, ensuring each meter of fabric is identical. Accurate digitization is the single most important factor for achieving pattern consistency, maintaining design integrity, and controlling production costs. It bridges the gap between artistic vision and manufacturing precision.

If you’re tired of costly sampling rounds and inconsistent quality, mastering the basics of lace digitization is your most powerful tool. Let’s explore the process, the key parameters, and how to collaborate effectively with your supplier to lock in perfection from the first sample.

Why is Professional Digitization Non-Negotiable for Lace Production?

Think of digitization as the DNA of your lace. A poor digital file is like flawed genetic code—the errors will replicate endlessly across every meter produced. The cost of fixing a digitization error during bulk production is astronomical, often requiring scrapping entire rolls. Professional digitization is not just about tracing a picture; it's about translating aesthetics into engineering language that a machine can execute with zero ambiguity.

The core challenge is that lace machines don’t “see” images; they follow coordinate-based commands. A professional digitizer understands the physical limitations and behaviors of the specific machine (Raschel, Leavers, embroidery) and the yarns being used. They will adjust the digital pathways to account for yarn tension, stretch, and shrinkage that occurs during production and finishing. For example, a beautiful, tight spiral in your artwork might need to be digitized with slight oval adjustments to compensate for the fabric’s natural bias pull, ensuring it appears as a perfect circle in the final washed product. This foresight separates amateurs from experts.

What Are the Common Pitfalls of Amateur Lace Digitization?

Understanding what can go wrong helps you spot issues early and demand better from your suppliers.

- Misaligned Pattern Repeats: The most common issue. The digital file doesn’t create a perfect “tile” that connects seamlessly end-to-end and side-to-side. This results in visible jumps or breaks in the pattern, ruining the garment’s appearance, especially on seams. In 2021, we audited a supplier for a UK client and found their digitizer was manually "eyeballing" repeats, leading to a 3mm cumulative error over 10 repeats—a disaster for tailored garments.

- Loss of Detail or Sharpness: Fine lines and small details in the original art can get lost or turn into blobs if the digitizer uses the wrong stitch type or density. This is crucial for logos or intricate geometric patterns.

- Poor Stitch Selection and Underlay: Different parts of a pattern require different stitch types (satin, fill, run) for stability and appearance. A missing or incorrect underlay (a foundational stitch layer) can cause the lace to collapse, wrinkle, or lack body.

- Ignoring Fabric Pull Compensation: As mentioned, every fabric pulls under tension. A digitizer who doesn’t account for this will produce a file that yields a distorted final product. Resources like the International Textile Manufacturers Federation (ITMF) discuss these technical parameters, but practical experience is king.

How Does Digitization Differ for Raschel vs. Embroidery Lace?

The core goal is the same, but the machine language and considerations differ significantly.

| Aspect | Raschel/Warp Knit Digitization | Embroidery Lace Digitization |

|---|---|---|

| Core Process | Creates a blueprint for interlooping yarns to form the ground and pattern simultaneously. | Creates a path for needles to stitch threads onto a pre-existing base fabric (like tulle). |

| File Type Focus | Focuses on guide paths for warp and weft directions, often proprietary to the machine manufacturer (e.g., Tricoma files). | Uses standardized embroidery files like DST, EXP, or PES. |

| Key Consideration | Must define the structure of the net ground and the solid pattern areas. Critical to program yarn carrier movements for efficiency. | Must manage thread density and stitch direction to prevent the base fabric from puckering or tearing. |

| Our Role at Shanghai Fumao | We work directly with our Raschel machine operators and programmers. We often digitize in-house for speed, adjusting files based on yarn samples before the machine even runs. | We collaborate closely with our dedicated embroidery factory partners, providing them with approved DST files after rigorous chenille and thread digitization testing. |

What Are the Essential Steps in the Lace Digitization Workflow?

A structured workflow is your blueprint for success. Don’t let your supplier skip steps.

- Provide Perfect Artwork: This is your responsibility. Supply high-resolution (300+ DPI), vector-based files (AI, EPS) if possible. Clean, clear artwork with distinct colors separating different elements (e.g., outline in red, fill in blue) is ideal. A fuzzy JPEG is the worst starting point.

- Specify Requirements Clearly: Your tech pack must include:

- Final Fabric Width

- Exact Pattern Repeat Dimensions (height and width)

- Yarn Type and Count (e.g., 40D Nylon, 20/2 Cotton). The digitizer needs this to calculate density.

- Desired “Hand Feel” (soft/draping vs. firm/structured).

- The Digitization Process: The specialist uses software to trace the artwork, assigning stitch types, densities, and sequences. They build in pull compensation and meticulously craft the repeat tile.

- Machine and Yarn Calibration: This is where many fail. The digital file must be tested on the actual production machine with the exact production yarns. A file calibrated for polyester will behave differently with cotton.

- Approval of the Strike-Off: The first physical sample from the digitized file is the “strike-off.” You must inspect it against your original artwork for pattern accuracy, repeat alignment, density, and hand feel. Measure the repeat with a ruler!

What Software and File Formats Are Industry Standard?

While many machine brands have proprietary software, the industry relies on a few key formats for communication:

- For Embroidery Lace: DST (Data Stitch Tajima) is the universal, machine-readable format. You may also receive or provide EXP (Melco), PES (Brother), or JEF (Janome). For editing and viewing, software like Wilcom ES or Hatch is professional-grade. We always provide our clients with a visual PDF of the stitch pattern alongside the DST file for double-checking.

- For Raschel/Knitted Lace: Formats are more varied (e.g., .TRI, .LNC). The communication here is often less about sending the file itself and more about approving a printed-out “layout” or “notation” from the machine software and, most importantly, the physical strike-off. Trusted suppliers like Shanghai Fumao manage this technical layer, giving you the simple choice: “approve” or “revise” the sample.

How Do You Check and Approve a Digitized Lace Sample?

Don’t just look—inspect. Here’s your checklist:

- Measure the Repeat: Use a precision tape. Is it exactly as specified?

- Check Seamlessness: Place two copies of the strike-off side-by-side and top-to-bottom. Does the pattern flow perfectly without a visible join?

- Assess Detail Fidelity: Use a magnifying glass. Are the finest lines from your artwork clearly defined?

- Test the Hand and Drape: Feel it. Is it too stiff or too flimsy? Does it match your reference sample?

- Review Under Light: Hold it up to a light source. Are there any unexpectedly dense or thin areas that create an uneven look?

Approving the strike-off is your final gate before bulk production. Once you sign off, you are confirming that the digital file is perfect. Any changes after this point will incur costs and delays. (A real-life example: A client in Italy once asked for a “slightly denser” feel after bulk production had started. The digitizer had to rewrite the entire file, recalibrate, and we lost three weeks. The lesson? Be decisive in the sampling phase.)

How Can You Collaborate with Your Supplier for Optimal Digitization?

This is a partnership, not a transaction. The best results come from open, technical communication.

- Start with a Reference: Always send a physical sample of the type of lace you want (even if the pattern is different). This gives the supplier’s digitizer and production team a concrete target for hand, weight, and opacity.

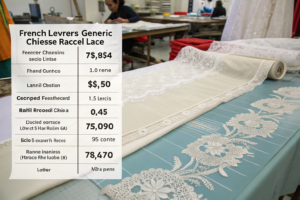

- Discuss Digitization Costs Upfront: Digitization is a skilled service. It may be charged separately (especially for original designs) or bundled into the sampling cost. Clarify this to avoid surprises.

- Plan for Multiple Sample Rounds: For complex patterns, budget for 2-3 strike-offs. The first translates art to fabric. The second refines density and alignment. The third is final confirmation. Rushing this is the #1 cause of bulk production failures.

- Leverage Your Supplier’s Expertise: Ask questions! “Do you think this motif will be stable in a 100% cotton yarn?” or “Can we adjust the digitization to make this more cost-effective without losing the look?” A good supplier will offer value engineering suggestions at the digitization stage. For instance, we recently suggested simplifying a background mesh fill for a client’s sustainable activewear line, reducing yarn usage by 15% and speeding up production, with no visual difference in the final product.

What Questions Should You Ask Your Potential Lace Supplier?

Vet their digitization capability ruthlessly:

- “Do you have in-house digitizers, or do you outsource this?” In-house control is vastly superior.

- “Can you walk me through your digitization and strike-off approval process?”

- “What information do you need from me to create the first accurate strike-off?”

- “What is your typical timeline and cost for developing a new digitized lace pattern?”

- “Can you show me examples where you fixed a digitization problem for a client?”

How Does Digitization Affect Lead Times and MOQs?

Digitization is part of your product development timeline, which sits before the production clock starts. Factor in 2-4 weeks for the digitization and strike-off approval process for a new design. This is especially critical to complete well before factory shutdowns like Chinese New Year. Having a perfected digital file ready to go means production can start immediately when factories reopen.

For Minimum Order Quantities (MOQs), a custom-digitized pattern will have a higher MOQ than choosing from a supplier’s stock design library. You’re paying for the development work. However, once the digital file is created, it’s an asset you own (clarify intellectual property rights!). You can re-order the same perfect lace for years, and the MOQ for re-orders is typically much lower.

How Does Digitization Enable Sustainability and Innovation?

Precise digitization is a powerful tool for sustainable manufacturing. It minimizes waste at the source.

- Material Efficiency: Accurate digitization optimizes yarn paths, reducing excess yarn usage. It ensures right-first-time production, slashing the fabric waste generated from faulty batches.

- Sample Reduction: A perfectly digitized file can produce a saleable strike-off, reducing the need for multiple physical sample rounds, saving materials, and shipping emissions.

- Enabling New Materials: Digitization allows us to confidently work with innovative but tricky yarns, like recycled polyester or delicate bamboo silk blends. By precisely controlling tension and density in the digital file, we can compensate for the unique behaviors of these eco-friendly fibers, ensuring they perform reliably in the final lace product. This technical capability is core to our mission at Shanghai Fumao.

What is the Future of Lace Digitization: AI and 3D Simulation?

The frontier is intelligent and predictive. We are beginning to experiment with AI tools that can suggest optimal digitization parameters based on an image and desired outcome, speeding up the initial setup. More immediately impactful is 3D simulation software. Soon, we may be able to show you a photorealistic 3D simulation of how your digitized lace will drape on a virtual garment before a single thread is produced. This will further reduce sampling waste and accelerate time-to-market. Staying ahead of these technologies is how we ensure our clients, and partners like Shanghai Fumao, remain competitive.

Conclusion

Digitizing lace patterns is the invisible, yet indispensable, engineering heart of luxury lace production. It transforms artistic inspiration into the precise, binary language of industrial machinery, guaranteeing the consistency, quality, and beauty that define premium apparel. By understanding the workflow, knowing the right questions to ask, and respecting the need for calibrated sampling, you shift from being at the mercy of your supplier to being in control of your product’s destiny. This process turns the risk of production surprises into the reassurance of predictable, repeatable excellence.

Mastering this step is what separates brands that struggle with quality from those that build a reputation for impeccable detail. It’s the technical foundation upon which beautiful collections are reliably built, season after season.

Ready to translate your most intricate lace designs into flawless, production-ready fabrics? Partner with a supplier who respects the science behind the art. Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss your next lace project. Let’s ensure your vision is digitized for perfection from the very first sample.