Walking through the textile markets of Keqiao and having visited the ateliers of Calais, I've faced this question more times than I can count. Just last month, a startup lingerie brand from Los Angeles asked me point-blank: "Should I pay 5 times more for French lace to be 'luxury,' or is Chinese lace just as good?" This isn't a simple yes or no. The truth is, the "quality difference" is not a binary of good vs. bad, but a spectrum of character, heritage, and application. Choosing between them is less about finding the objectively "better" lace and more about matching the fabric's soul to your brand's story, budget, and technical needs.

The core quality difference between French and Chinese lace lies in heritage craftsmanship versus modern, scalable innovation. French lace (particularly from Calais and Caudry) is renowned for its Leavers lace—produced on historic looms, offering unique depth, slight imperfections, and unparalleled prestige for haute couture. Chinese lace, led by clusters like Keqiao, excels in high-quality Raschel and embroidery laces, offering exceptional consistency, innovative blends (like stretch lace), rapid sampling, and competitive pricing for the commercial luxury and mid-market segments. The "best" choice depends entirely on your brand positioning, design complexity, and volume needs.

Let's be brutally honest: if you're making 50,000 units for a global fast-fashion retailer, French Leavers lace is economically and logistically impossible. Conversely, if you're crafting a limited-edition bridal gown with a six-figure price tag, a generic Chinese Raschel lace won't carry the narrative. The real skill in sourcing is knowing not just what each region produces, but how their production ecosystems work, and how to leverage the strengths of both. This guide will cut through the romance and the prejudice, giving you a clear-eyed comparison to make an informed, strategic decision.

What Defines the Heritage and Craft of Authentic French Lace?

When you buy French lace, you're not just buying fabric; you're buying centuries of history. The heart of this is Leavers lace, named after the English inventor but perfected in France. I handled a piece of Caudry Leavers lace in 2022 for a client's wedding dress; its texture had a living, three-dimensional quality that no digital file can replicate. The process is astonishingly slow—a single worker might produce just a few centimeters a day on these antique, sometimes 100-year-old, looms. The patterns are fed via intricate punch cards, a technology predating computers. This inherent limitation is also its magic: the slight variations in thread tension and the tiny, beautiful imperfections are seen as a mark of authenticity, not a defect.

The heritage of French lace is protected by geographical indications (GI), much like Champagne. Lace from "Caudry" or "Calais" carries this badge of origin, guaranteeing a specific method of production. The quality hallmarks are unmistakable: an exceptionally soft hand (feel), a complex, multi-tiered depth to the pattern, and a lightweight drape that seems to float. The fibers are traditionally premium: fine Egyptian cottons, luxurious silks, and sumptuous viscose. This lace is made for moments, for heirlooms. However, this heritage comes with constraints: extremely high minimum order quantities (MOQs) for custom designs (often 500+ meters), lead times measured in many months, and a price point that can exceed €100-€300 per meter. It is a supply chain built for patience and prestige.

Is "Made in France" Always Synonymous with Leavers Lace?

No, and this is a critical sourcing nuance. Not all lace produced in France is Leavers lace. The region also produces:

- Raschel Lace: Made on modern electronic knitting machines. It's faster and more affordable but lacks the signature depth of Leavers. It's often used for broader market segments.

- Embroidered Lace (Guipure): Where a pattern is embroidered onto a base that is later dissolved.

When sourcing, you must specify. Ask for the "Leavers" designation and the GI proof. A true Leavers supplier will be proud to provide it. For brands that want the "Made in France" label with slightly more flexibility, high-end French Raschel is a viable, though still premium-priced, option.

How Do French Mills Handle Customization and Innovation?

Customization is a slow, profound collaboration. You work with a dessinateur (pattern designer) to create a unique carton (pattern). This is an artistic process, not just a technical one. The lead time for a new design can be 6-12 months. Innovation is often about preservation and refinement of traditional techniques rather than radical new fibers. However, some mills are innovating with recycled threads and eco-certifications to meet modern demands. The process is not agile, but for the right project, it is unparalleled. For a deep dive into this world, the Caudry Lace Center's heritage and technical guides are an authentic resource.

How Has Chinese Lace Evolved to Dominate Global Markets?

The rise of Chinese lace is a story of industrial transformation. Forty years ago, Keqiao was a local market. Today, it's a cluster where you can find a mill specializing in nothing but lace for sports bras, or a factory that perfects digital printing on lace netting. The key driver is vertical integration and speed. At Shanghai Fumao, when a client requests a new design, our R&D team can create a digital CAD file in hours, program a Raschel machine in days, and produce a saleable sample within a week. This agility is impossible in the traditional French system.

Chinese quality is now tiered, and the high-end is formidable. Top-tier Chinese mills produce lace for global luxury brands—you'd be surprised how many "European" labels source specialty laces from Keqiao. The focus is on precision, consistency, and technical innovation. Chinese engineers have mastered complex elastic laces for athleisure, seamless tube laces, and hybrid fabrics combining lace with mesh, velvet, or sustainable materials like recycled Bemberg. Our CNAS-certified lab ensures every batch meets strict colorfastness and shrinkage standards (e.g., ISO 105, ISO 5077). The value proposition is clear: high aesthetic quality, reliable technical performance, scalable volumes, and lead times 60-70% shorter than traditional European sources.

What Are the Real Quality Tiers Within Chinese Lace Production?

Understanding this tiering is essential to avoid disappointment:

- Premium/Export Grade: Produced in audited, high-tech factories with strict QC. Uses quality yarns (sometimes imported) and advanced finishing. MOQs can be as low as 300-500 meters per design/color. This is what we provide at Shanghai Fumao.

- Commercial Grade: For domestic and volume export markets. Good quality for the price but may have more visual consistency flaws. Focus is on speed and cost.

- Market Grade: Sold in local fabric markets. Variable quality, often with sizeable defects. For sampling or ultra-low-cost projects only.

The gap between Premium Chinese lace and French Leavers is narrowing in appearance but remains distinct in provenance and craft narrative.

How Does Chinese Sourcing Master Technical and Sustainable Demands?

Chinese suppliers lead in responding to technical briefs. Need a lace with 30% stretch recovery, UPF 50+, and Oeko-Tex Class 1 certification for babywear? That's a standard R&D project here. Sustainability is a major growth area: we've seen a 200% increase in requests for GOTS certified organic cotton lace and recycled polyester laces in the past two years. The supply chain's responsiveness allows for rapid iteration on these functional fabrics. However, the onus is on the buyer to conduct due diligence—audit reports, test certificates, and factory visits are non-negotiable to ensure ethical and quality standards are met.

Side-by-Side Comparison: When to Choose Which?

Let's move from theory to a practical decision matrix. The choice isn't about "better," but about "right for the job." Here is a breakdown to guide your sourcing strategy.

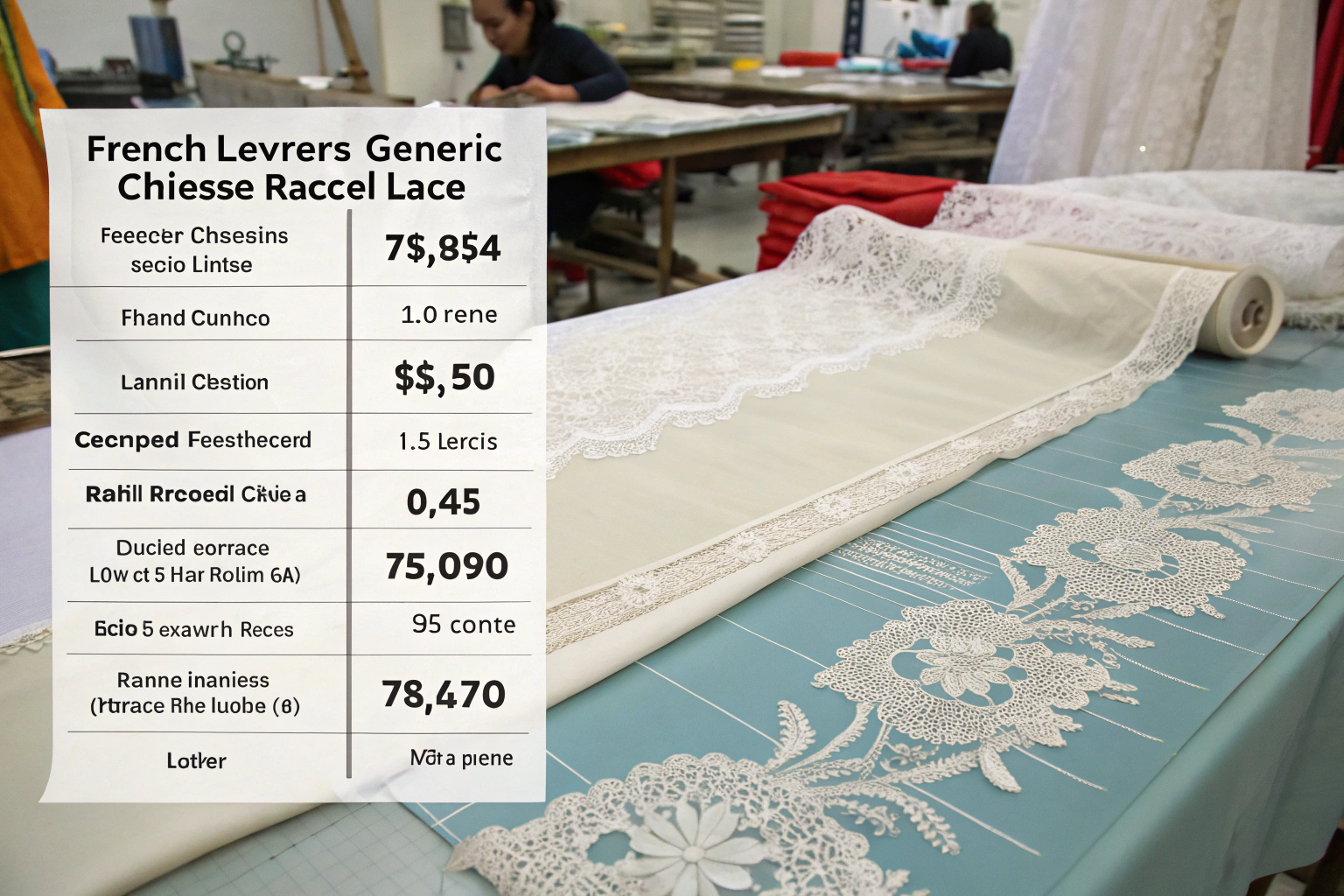

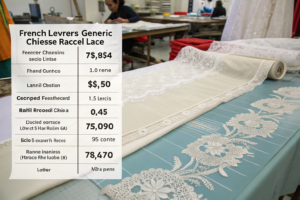

| Decision Factor | French Leavers Lace (Caudry/Calais) | Premium Chinese Lace (e.g., Keqiao) | Verdict & Tip |

|---|---|---|---|

| Brand Narrative | Essential. For heritage, "artisanal," "haute couture" storytelling. | Flexible. Supports "innovative," "technical," "accessible luxury" narratives. | Choose French if provenance is a core selling point. Choose Chinese for narrative flexibility. |

| Budget | Very High (€100-€300+/m). For margins >70%. | Competitive ($10-$50/m). Enables healthier margins at mid-price points. | Choose Chinese for scalable, commercially viable luxury. |

| Lead Time | Long (4-12 months). For planning years ahead. | Short (45-90 days). For responsive, trend-driven cycles. | Choose Chinese for agility. Choose French only with long-term planning. |

| Custom Design MOQ | High (500-1000m+). | Low (300-500m). Supports small-batch customization. | Choose Chinese for startups, testing, and smaller collections. |

| Technical Innovation | Limited. Focus on traditional fibers & weaves. | High. Specialists in stretch, performance finishes, fiber blends. | Choose Chinese for functional apparel (sportswear, activewear). |

| Consistency | Variable. Imperfections are part of the charm. | High. Batch-to-batch precision for large runs. | Choose Chinese for large orders where uniformity is critical. |

For a Bridal or Haute Couture Line, Is French Always Superior?

Not automatically. Consider this:

- Choose French Leavers for: The main bodice of a $20,000 couture gown where the lace is the star. The client is paying for the story and the singular artifact.

- Consider Premium Chinese for: Bridesmaid dresses, veil overlays, or appliqués where you need volume, color matching across 50 units, and a budget under $5,000 for fabric. The quality can be stunning, and the savings are transformative for your business margin.

A UK bridal designer we work with uses French Leavers for her flagship "couture" collection (12 pieces a year) and our premium Chinese embroidered laces for her "ready-to-wear" bridal line (200 pieces a year). This hybrid strategy maximizes both prestige and profitability.

Can Chinese Suppliers Faithfully Replicate Historic French Patterns?

This is a delicate art. Yes, top Chinese mills can replicate the visual appearance of a Chantilly or Alençon lace with remarkable accuracy using high-definition Raschel or embroidery machines. However, experts will notice the difference in hand and drape. The replica will be more consistent, often slightly stiffer, and lack the subtle depth. It is a faithful interpretation, not a duplicate. For most consumers, this difference is invisible. The key is transparency: never sell it as "French lace," but as "lace inspired by French design." The history and identification of traditional lace types can help you and your team appreciate the authentic details.

How to Source Smartly: A Tactical Guide for Buyers

Your sourcing strategy should be as sophisticated as your designs. It’s not about picking a side, but about building a diversified, resilient supply portfolio.

- Start with Your Tech Pack: Be ruthlessly specific. Is "soft hand" defined by a specific Martindale rub test score? Define quality quantitatively. This allows Chinese suppliers to meet objective standards and lets you compare apples to apples.

- Sample Extensively: Always, always get physical handfeel samples. A digital image tells you 10% of the story. Order sampling yardage (5-10 meters) from shortlisted suppliers in both regions. Make a prototype garment and test it—wash it, stretch it, wear it.

- Conduct Due Diligence: For French mills, verify GI status and visit if possible. For Chinese suppliers like us at Shanghai Fumao, ask for: CNAS/SGS lab test reports, factory audit reports (SMETA, BSCI), and request a live video tour of the facility. Check their track record with brands in your segment.

- Plan for the Long Term: If you choose French lace, integrate its lead time into your 2-year design calendar. If you choose Chinese, build a relationship with a key supplier. We become an extension of our clients' R&D teams, advising on seasonal trends and production planning to navigate peak seasons and CNY.

What Are the Hybrid and Future Trends?

The future is not "either/or," but "and." The smartest brands are blending:

- French Lace Appliqués on Chinese Bases: Using small amounts of exquisite French lace as focal points on garments made with premium Chinese base fabrics.

- Chinese Innovation with European Design: European designers are creating patterns specifically for China's high-tech looms, achieving new aesthetics at viable costs.

- Sustainability as the New Luxe: Both regions are racing to develop carbon-neutral lace production and biodegradable lace fibers. The leader in this new category is still up for grabs.

Conclusion

The question of quality difference between French and Chinese lace is, ultimately, the wrong question. The right question is: "Which supply ecosystem aligns with my brand's identity, business model, and customer expectations?" French lace offers an irreplaceable heritage and artisanal soul for the pinnacle of luxury. Chinese lace delivers world-class technical quality, innovation, and supply chain efficiency for the dynamic global market.

For most brands building a sustainable, scalable business, premium Chinese lace from a reputable, vertically-integulated supplier like Shanghai Fumao presents the most strategic and balanced value proposition. It allows you to achieve stunning aesthetic results, meet rigorous performance standards, and maintain healthy margins without the narrative constraints of ultra-limited supply. Let us help you navigate this choice with clarity. Send us your tech pack or inspiration, and we'll provide samples that demonstrate what modern Chinese lace excellence truly means. Contact our Business Director, Elaine, at elaine@fumaoclothing.com to begin a practical, sample-driven conversation.