As the owner of a fabric manufacturing and export company based in Keqiao, I’ve spent over two decades watching trends come and go. But one thing remains constant: the magic of lace in intimate apparel. Every year, designers and brands from New York to Moscow come to us asking for “the best lace.” They often arrive confused by the overwhelming choices and technical jargon. I get it. With so many types—Chantilly, Leavers, Guipure, embroidered—how do you pick the right one that balances luxury, comfort, durability, and cost? Let me share a secret: the “best” lace isn’t a single fabric; it’s the perfect match between your design vision, your budget, and a supplier who truly understands both craftsmanship and your timeline pressures.

The best lace fabrics for lingerie are those that combine aesthetic delicacy with physical durability, skin comfort, and design functionality. For luxury pieces, Chantilly and Leavers lace offer unparalleled fineness and prestige. For everyday comfort and stretch, embroidered laces on stretch mesh or powernet are ideal. For structured designs and bold motifs, Guipure (or chemical lace) is the top choice. The selection ultimately depends on your specific application—whether for bras, panties, bodysuits, or accessories—and must consider fiber content (like nylon, polyester, or cotton), construction method, elasticity, and colorfastness. At Shanghai Fumao, we guide our clients through this maze by providing samples and real-world data on how each lace performs in actual garment production.

Choosing the right lace can make or break your intimate apparel line. It’s not just about how it looks on a mood board; it’s about how it feels against the skin, how it holds up after 50 washes, and how efficiently it can be cut and sewn in your factory. In this guide, I’ll demystify the world of lingerie lace, drawing from our vast library of over 30,000 designs and countless client projects. We’ll explore the top contenders, their pros and cons, and crucially, how to source them smartly by understanding the rhythms of Chinese manufacturing. This knowledge is your key to creating pieces that are as beautiful in quality as they are in design.

What is Chantilly Lace and Why is it a Luxury Choice?

Picture this: a designer from Los Angeles emails us in a panic. It’s March 2023, and she needs a specific black floral lace for a high-end lingerie collection launching in September. She sends a blurry photo from a vintage catalog. “I need this feel,” she says. Our R&D team knew instantly—she was describing Chantilly lace. We developed a sample in 48 hours, matching the delicate, scalloped outline and fine, outlined floral patterns on a nearly invisible net background. When she received it, her reply was one word: “Perfect.” That’s the power of knowing your lace.

Chantilly lace, historically hailing from France, is synonymous with luxury lingerie. It’s characterized by its fine, delicate patterns (often floral or botanical) outlined with a slightly heavier thread (cordénet) on a lightweight net ground. The result is a lace that is elegant, feminine, and exceptionally drapey. Its beauty lies in its contrast and definition. For brands aiming at the premium market, using authentic Chantilly or high-quality reproductions signals top-tier craftsmanship. However, true Leavers-made Chantilly is rare and expensive. Most modern “Chantilly” is produced on Raschel or Jacquard machines, which can mimic the aesthetic at a more accessible price point while offering more consistency and faster production—a key advantage we leverage at Shanghai Fumao for our global clients.

How Does Leavers Lace Differ from Raschel Lace?

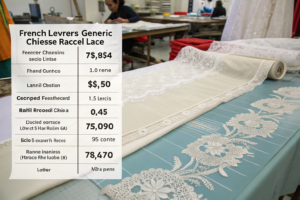

This is the “handmade vs. machine-made” debate of the lace world. Leavers lace is the gold standard. Made on antique Leavers looms (many original machines are still in use!), it’s slower to produce, has slight, beautiful imperfections, and possesses a unique depth and texture that machines struggle to copy perfectly. It’s the choice for haute couture. Raschel lace, on the other hand, is made on modern, high-speed Raschel knitting machines. It’s more cost-effective, highly consistent, and fantastic for complex designs with elastane for stretch. The choice boils down to your brand positioning and budget.

| Feature | Leavers Lace | Raschel Lace |

|---|---|---|

| Production Method | Traditional looms, slower | Modern knitting machines, faster |

| Texture & Feel | Softer, more pliable, unique depth | Can be slightly stiffer, very consistent |

| Elasticity | Generally non-stretch (unless blended) | Can easily integrate spandex for 20-30% stretch |

| Cost | Very High | Moderate to High |

| Best For | Heirloom, luxury pieces, limited editions | High-quality commercial lingerie, everyday luxury |

| Minimum Order | Often high due to craft | More flexible, supports small-batch customization |

For most of our commercial clients, high-end Raschel lace is the sweet spot. For instance, a UK-based brand in 2022 wanted a sustainable lace. We developed a Raschel lace using GOTS certified organic cotton blended with elastane for them, which provided the luxury look with the comfort and stretch modern consumers demand, all while meeting their ethical sourcing goals.

What Are the Key Quality Tests for Lingerie Lace?

You can’t judge lace by looks alone. A beautiful lace that shrinks 10% in the first wash or bleeds color is a disaster. Our CNAS-accredited lab runs every new lace development through a battery of tests before it goes to a client. Here are the non-negotiables:

- Dimensional Stability (Shrinkage): We test washing and drying according to ISO 5077. For lingerie, we aim for less than 3% shrinkage. A lace that shrinks more than that will pucker and ruin the fit of a bra cup.

- Colorfastness: This includes rubbing (dry and wet), washing, and perspiration (ISO 105 standards). No one wants black lace to turn a white bra strap grey. We ensure a rating of 4-5 for premium lines.

- Stretch and Recovery: For elastic laces, we measure how much it stretches under a specified force and, crucially, if it returns to its original shape. Poor recovery means a garment will bag out. (Here’s a pro tip: always ask your supplier for the test report. A reputable one like Shanghai Fumao will provide it upfront.)

Understanding these technical specs is vital. A great resource for building your quality checklist is this guide on key fabric quality tests for apparel sourcing from an industry forum like Sourcing Journal.

How to Choose Between Stretch and Non-Stretch Lace?

Let’s talk about a common pain point: fit. In early 2024, we worked with an emerging Australian active-inspired lingerie brand. They loved a rigid, non-stretch Guipure lace for its bold pattern but were struggling with comfort in their sports bralette line. The solution wasn’t to abandon the design; it was to re-engineer the product. We helped them use the non-stretch lace as an exterior overlay for style, sewn onto a separate, highly supportive and stretchy powernet base layer. Problem solved. This is the kind of practical application knowledge that comes from years in the field.

The choice between stretch and non-stretch lace is fundamentally about the garment’s function and comfort. Non-stretch laces (like many Chantilly or Guipure) offer superior pattern definition and a crisp, luxurious drape. They are ideal for parts of a garment where structure is needed—like the front panel of a babydoll, or as appliqués. Stretch laces, typically Raschel laces with 5-20% elastane (spandex) content, are the workhorses of modern lingerie. They conform to the body, allow for a wider size range with fewer pattern pieces, and provide all-day comfort, making them essential for panties, bralettes, and the sides of bras.

When Should You Use Elastic Lace (Elastane Blends)?

Use elastic lace virtually anytime you need the garment to move with the body. Here’s a quick guide:

- Bra Cups & Side Panels: For wireless or soft-cup bras, stretch lace provides gentle support and adapts to breast shape.

- Panties: The leg openings and waistbands benefit massively from stretch lace for a non-digging, comfortable fit.

- Bodysuits & Camisoles: Stretch lace across the torso ensures the garment stays in place and moves comfortably.

- Sheer Sleeves or Overlays: Stretch lace sleeves are trending; they offer a sexy, fitted look without restricting arm movement.

However, not all stretch is equal. The percentage and quality of elastane matter. Cheap elastane can break down with heat and chlorine. We always recommend testing for chlorine resistance if the lingerie might be used for swimwear or could be exposed to spa chemicals. For a deep dive into the science of elastane, how to choose the right spandex content for performance apparel is an excellent read from a textile engineering blog.

What is the Role of the Ground Fabric (Net, Mesh, Tulle)?

The ground fabric is the unsung hero. It’s the base upon which the lace pattern is built or applied. The choice of ground drastically alters the final fabric.

- Stretch Net/Mesh: The most common base for modern stretch laces. It’s lightweight, breathable, and provides the elasticity. The density of the mesh affects sheerness and strength.

- Non-Stretch Tulle: Used for traditional laces. It’s stiff and provides a stable base for intricate patterns but offers no give.

- Powernet: A heavier, high-control mesh with two-way or four-way stretch. When combined with a lace pattern (often through embroidery), it creates a “power lace” perfect for shaping in high-support bras or corsetry.

A European client last August wanted a “second-skin” feel for a luxury collection. We developed a custom lace using a super-soft, OEKO-TEX certified polyamide micro-mesh as the ground. It was more expensive, but the tactile result justified the cost and became their signature fabric. The key is to specify your ground fabric requirements clearly to your supplier.

What Are the Pros and Cons of Guipure (Chemical) Lace?

Guipure lace, sometimes called “tape lace” or “chemical lace,” is the bold statement maker. I remember a Russian client in November 2023 who was adamant about using a heavy, floral Guipure for a winter collection. The look was stunning, but we had to have a frank discussion about cost and waste. Because Guipure has no net ground—the motifs are connected by threads or bars—it’s heavier, less drapey, and the cutting yield is lower. You need more fabric per garment because you must align and cut around the solid motifs carefully. We helped them optimize their marker (the fabric layout plan) to increase efficiency, saving them 15% on material costs.

Guipure lace is defined by its dense, embroidered-like patterns where the motifs are connected by bars or braids, not a net background. This gives it a substantial, textured, and often three-dimensional feel. It’s non-stretch and offers superb opacity and structure. Pros: Unmatched visual impact, great for bold geometric or art deco patterns, provides structure and body, often looks more expensive than it is. Cons: Heavier, less flexible, can be itchy if not backed with a soft lining, generates more fabric waste during cutting, and may require special handling during sewing to prevent fraying.

Is Guipure Lace Comfortable for Everyday Wear?

On its own, directly against the skin, Guipure can be scratchy due to the raised, dense threads. The key to comfort is in the garment construction. High-quality lingerie always lines Guipure with a soft, skin-friendly fabric like silk habotai, breathable cotton voile, or a microfiber blend. The lining protects the skin and also adds to the garment’s durability by preventing the lace from snagging. For items like bras, the Guipure is often used as an outer layer for aesthetics, while the inner cup is made from a molded foam or a soft, stretch fabric. Always request a lined sample from your manufacturer to assess the final feel.

How is Embroidered Lace Different from Traditional Lace?

This is a crucial distinction. Traditional lace (like Leavers, Raschel) is created in one step—the pattern and ground are formed together. Embroidered lace (including most Guipure) is made in two steps. First, a pattern is embroidered onto a temporary base fabric (like a soluble stabilizer or a lightweight substrate). Then, the base fabric is dissolved away chemically or washed away, leaving only the embroidered pattern. This is why it’s often called “chemical lace.”

- Advantage of Embroidered Lace: It allows for incredibly detailed, dense, and multi-colored patterns that are hard to achieve on traditional looms. It’s highly customizable.

- Disadvantage: The chemical process involves more steps and requires strict environmental controls. You must work with a supplier like Shanghai Fumao that partners with certified, responsible printing and embroidery factories to ensure wastewater is treated properly. For brands with a strong sustainability focus, it’s important to discuss these processes upfront.

How Do Chinese Production Cycles Affect Lace Sourcing Timelines?

This is the reality check every international buyer needs. Your beautiful lace design means nothing if it misses the production window. A classic story: An American e-commerce brand in late October 2022 finalized a gorgeous lace for their Valentine’s Day collection. They planned for a standard 8-week production. What they didn’t factor in was the Chinese New Year (CNY) shutdown. Their timeline fell right in the CNY period, delaying everything by a month. They missed their launch. We now advise all our clients on this religiously.

Chinese manufacturing follows a predictable yet powerful rhythm that you must master to avoid costly delays. The peak production seasons are March-May and August-October. During these months, factories are at full capacity. Even with our agile supply chain, adding 1-2 weeks to your standard timeline for sampling and production is prudent. The major holiday shutdowns are non-negotiable: Chinese New Year (3-4 weeks in Jan/Feb) and National Day Golden Week (1 week in October). Planning must work around these. Conversely, slower periods like June-July and November-December can offer potential timeline advantages and sometimes more negotiation power.

How to Plan Your Order Before Chinese New Year?

The golden rule: Complete all pre-production at least 6 weeks before the CNY holiday. This means:

- Finalize Fabrics: Have your lace and all other materials approved, lab-tested, and physically in the factory’s warehouse. Do not leave fabric sourcing until after CNY.

- Seal Samples: Get your fit samples, pre-production samples, and shipping samples signed off. Any revisions need to be done before the holiday exodus.

- Place Deposit: Ensure your production order is confirmed and the deposit is paid to secure your slot in the production queue for immediately after the holiday.

A savvy European fast-fashion brand we work with has this down to a science. They target to have their pre-production for summer lace collections wrapped up by early December. This allows their factory to start cutting the first batch the very week workers return, ensuring they hit their March store delivery dates flawlessly.

What Are the Hidden Risks During Peak Seasons?

Peak seasons bring hidden costs and risks beyond just longer lead times:

- Quality Fluctuation: Overworked factory lines can lead to more errors. Our QC team doubles down on inspections during these periods. We implement inline inspections for all peak-season orders.

- Logistics Bottlenecks: Ports get congested, and container rates spike. Booking shipping space in advance is critical. We leverage our long-term relationships with freight forwarders to secure space for our clients.

- Subcontracting: Some overbooked factories might subcontract work without your knowledge, leading to quality inconsistencies. We maintain full vertical control over our key processes and are transparent about our partner factories, which are all audited.

For reliable information on navigating these logistics challenges, checking resources like understanding sea freight schedules from China to the USA on logistics-focused websites is invaluable. Planning isn’t just about the factory floor; it’s about the entire journey to your warehouse.

Conclusion

Choosing the best lace for your lingerie line is a blend of art and science. It starts with understanding the unique personalities of Chantilly, Guipure, and embroidered stretch laces, and matching them to your design’s functional and emotional needs. It’s solidified by insisting on rigorous quality testing for shrinkage, colorfastness, and durability. And it’s ultimately brought to life through smart, realistic planning that respects the powerful cycles of Chinese manufacturing. The goal is to transform that beautiful swatch into a flawless, profitable garment that arrives on time.

Your vision deserves a partner who not only supplies fabric but also provides the roadmap to get it made successfully. At Shanghai Fumao, we’ve been that partner for over 100 brands across the globe. From our roots in the Keqiao textile cluster, we offer more than just our vast library of 30,000+ lace and fabric designs. We offer the expertise to navigate development, the rigorous QC to ensure quality, and the seasoned advice to plan around production peaks and holidays. Let’s co-create your next iconic collection. Ready to discuss your specific lace needs and timeline? Reach out directly to our Business Director, Elaine. She and her team will provide you with tailored samples and a clear production strategy. Contact Elaine at elaine@fumaoclothing.com to start the conversation.