You're designing a new collection. For the body-hugging cocktail dress, you know you need stretch. For the flowing evening gown overlay, you think you don't. But when you get the samples, something's off. The stretch lace on the dress feels cheap and loses its shape. The non-stretch lace on the gown pulls at the seams and restricts movement. You've just experienced the core dilemma of lace selection: stretch versus non-stretch isn't just about elasticity; it's about matching the fabric's inherent physics to your garment's functional purpose. Choosing wrong can compromise fit, comfort, and the entire design vision.

At Shanghai Fumao, we field this question daily from brands worldwide. The answer isn't binary; it's a spectrum defined by construction, fiber, and finish. This guide will move beyond "one stretches, one doesn't." You'll learn how they're fundamentally made, where each excels (and fails), and how to make the definitive choice for your specific design—ensuring the lace you source performs as beautifully as it looks on the mood board.

Let's unravel the threads. Understanding this difference is the first step to sourcing like a pro and designing with confidence.

How Are Stretch and Non-Stretch Lace Structurally Different?

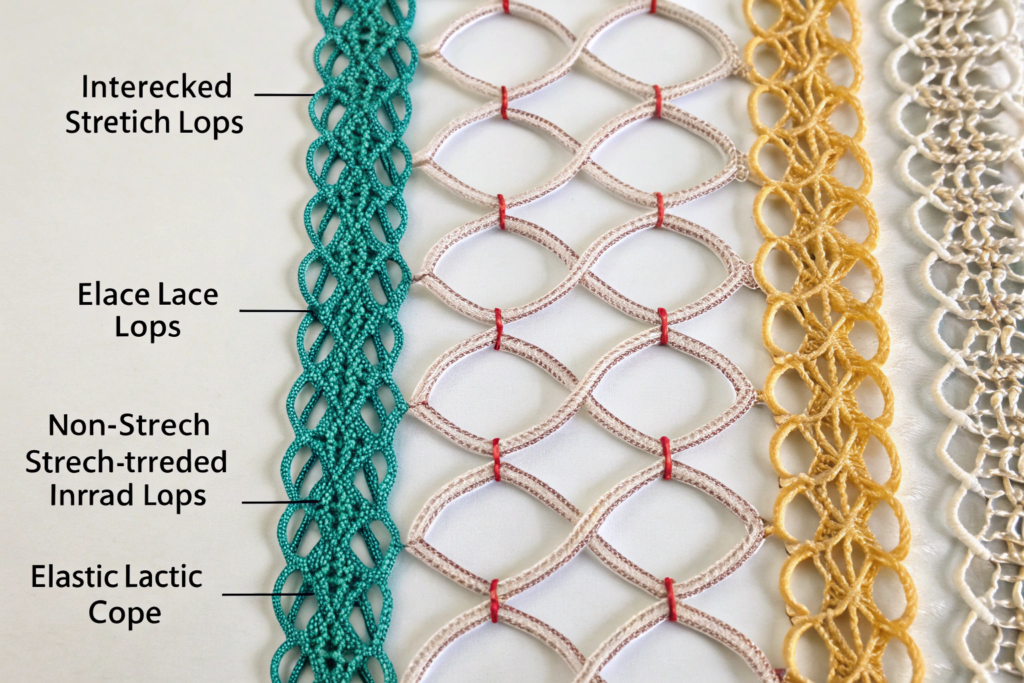

The core difference is in their DNA—their construction. Non-stretch lace is typically created on Leavers or Raschel machines using only inelastic yarns like standard polyester, nylon, cotton, or rayon. The loops and twists in the structure are locked, creating a stable, fixed fabric. It’s like a chain-link fence; strong and firm. Stretch lace, however, is almost exclusively a product of modern Raschel knitting machines that incorporate an elastic yarn, most commonly Lycra (spandex), directly into the construction. This elastic yarn can be plied with the face yarn or laid in as a separate, hidden thread within the knit structure. Every loop in the fabric has a tiny "spring" inside it.

This structural difference dictates everything. Non-stretch lace offers crisp definition and dimensional stability—perfect for motifs that need to hold their shape. Stretch lace is inherently dynamic; its pattern will widen and contract with the movement of the fabric. At Shanghai Fumao, when we develop a stretch lace, one of our first R&D tests is for "power" and "recovery"—measuring how much force it takes to stretch it and, critically, how completely it snaps back to its original shape. A lace that stretches out and stays out is useless.

What Specific Yarn Makes Lace Stretch, and How is it Integrated?

The magic ingredient is elastane, branded as Lycra, Dorlastan, or Creora. This synthetic fiber can be stretched repeatedly to over 500% of its length and still recover. In lace production, it's used in very low percentages—typically between 5% and 20%—because a little goes a very long way.

There are two primary integration methods:

- Bare Lycra Feed: A bare, thin elastane yarn is fed directly into the knitting zone of the Raschel machine alongside the non-stretch face yarns. It gets caught in the loops, creating an all-over, inherent stretch.

- Covered Spandex Yarn: The elastane filament is first wrapped (covered) with a nylon or polyester thread. This covered yarn is then used in the lace construction. It can offer more control and a softer feel.

The choice affects hand feel and performance. For a luxury Italian lingerie brand we supply, they insist on lace with 15% covered Lycra for their high-end line, as it provides a smoother, more consistent tension against the skin. For activewear, a higher percentage of bare Lycra might be used for greater power. Understanding the role of spandex in performance fabrics can provide deeper context for technical applications.

Why Can Some Lace Be "Mechanically" Stretched Even Without Lycra?

This is a crucial point. A lace made from 100% nylon on a Raschel machine may have a small amount of "mechanical stretch" or give due to the nature of the knitted loop structure. Think of it like a knitted sweater—it can be pulled a bit. However, this is very different from true "elastic stretch." Mechanical stretch has poor recovery; it will bag out. It also usually only occurs in one direction (often widthwise). True elastic stretch with Lycra offers multi-directional recovery and is engineered to return to its original shape wash after wash. Never confuse the two when specifying for a garment that requires real fit and hold.

When Should You Definitely Choose Stretch Lace?

Stretch lace is a functional problem-solver. Its primary domain is any garment where close contact with the body and freedom of movement are non-negotiable. The most obvious category is Lingerie and Shapewear. Here, stretch lace provides comfort, eliminates gaping, and creates a smooth, contoured look. It's also essential for Bodysuits, Swimwear, and Activewear, where it must withstand dynamic movement and chlorine or sweat exposure.

Beyond intimate apparel, stretch lace is revolutionary for ready-to-wear. It allows for simplified size grading, as a single piece can accommodate a range of body shapes with gentle compression. This reduces inventory complexity and can lower return rates due to fit issues. For sleeves, turtlenecks, and fitted panels on otherwise woven garments, stretch lace inserts can add visual interest without compromising mobility. We worked with a London-based contemporary brand that used our 4-way stretch lace as insets on the sides of a woven satin skirt. This allowed for a pencil-silhouette that women could actually walk and sit in comfortably—a small detail that generated rave reviews.

What Are the Key Specifications to Check When Ordering Stretch Lace?

Ordering "stretch lace" is not enough. You must specify:

- Stretch Direction: Is it 2-way stretch (usually horizontal) or 4-way stretch (both horizontal and vertical)? Activewear requires 4-way; many fashion laces are 2-way.

- Stretch Percentage: How far does it stretch? A 50% stretch means a 10cm piece can stretch to 15cm. Lingerie may need 30-50%, activewear 50-100%.

- Reccovery Rate: This is the most important. Ask for test data. A good recovery is >95% after multiple stretch cycles.

- Power: The "push-back" feeling. High power is for control garments, low power for decorative overlays.

Neglecting these specs is the #1 reason for production failures. In early 2023, a US dress brand received a bulk shipment of stretch lace for a fit-and-flare dress bodice. The lace stretched widthwise as intended, but had zero vertical give. When the wearer sat down, the lace didn't yield, causing the side seams to pull and eventually tear. The issue was a mis-specified 2-way stretch when the pattern required slight vertical ease. We helped them correct this for their next season by providing full specification sheets.

Can Stretch Lace Be Used for Structured Garments?

Yes, but with clever engineering. It can be fused or backed with a non-stretch stabilizer (like woven interfacing or power net) to create a composite material. The stretch lace provides the aesthetic surface, while the backing provides the control and structure. This is common in corsetry, structured bustiers, and the cups of padded bras. The key is ensuring the adhesive or bonding method used can withstand the tension of the stretching lace without delaminating.

When is Non-Stretch Lace the Superior and Necessary Choice?

Non-stretch lace is the guardian of form, detail, and tradition. Its strength lies in its stability. Use it when you need crisp, unwavering motif definition, structural integrity, or a specific drape. The prime example is Bridal and Formal Eveningwear. A ball gown skirt overlay in non-stretch lace will hang in perfect, graceful folds without distorting the elaborate pattern. A veil needs to hold its shape, not cling.

It's also the choice for applications where the lace is not meant to move with the body: trims, collars, cuffs, handbags, shoes, and home décor items like table runners or curtain panels. Furthermore, many historical, vintage, or haute couture techniques rely on the precise behavior of non-stretch lace for techniques like smocking, intricate seaming, and appliqué on structured bases. Trying to do these techniques with stretch lace would lead to unpredictable, rippled results.

How Does Drape Differ Between the Two Types?

Drape is a direct result of structure. Non-stretch lace has a more predictable, often heavier drape. It can be crisp (like in Guipure) or fluid (like in fine Chantilly), but it moves as a whole piece. Stretch lace has a more fluid, forgiving, and sometimes "clingy" drape due to its ability to contract. It follows body contours more closely. This is why a stretch lace used as an overlay on a loose chiffon dress can create an unwanted, tensioned look—the two fabrics are fighting each other. For a successful design, the drape characteristics of all fabric layers must be compatible. Researching fabric drape coefficients and garment design can provide a more scientific framework for this.

What Are the Cutting and Sewing Implications for Each Type?

This is where production planning is critical. Non-stretch lace is cut and sewn like any other woven fabric. Patterns can be precise, and seam allowances are stable. Stretch lace requires special handling:

- Cutting: It must be cut "at rest," never stretched out on the cutting table, or the pieces will shrink post-cutting and not match the pattern.

- Sewing: Use a ballpoint needle and a stretch or narrow zigzag stitch. A straight stitch will pop when the fabric stretches.

- Stabilizing: Strategic stabilizer tape may be needed at shoulder seams or zippers to prevent stretching out during wear.

Factory workers need training to handle stretch materials. We often provide our clients with a brief "handling guide" for our stretch laces to prevent production errors. For small brands, mastering sewing techniques for stretch fabrics on home machines is an essential skill.

Conclusion

The decision between stretch and non-stretch lace isn't about trend; it's about design intent and function. Start by asking: What is the primary action of this garment? Is it to hug and move with the body, or to create an external shape and statement? What are the stress points? Will the lace be over a joint (elbow, knee) or in a stable area?

Remember, you can also use them in combination. A non-stretch lace appliqué on a stretch lace base is a common and beautiful technique in lingerie, offering both detailed artistry and overall comfort. At Shanghai Fumao, we help designers navigate these choices daily, often by providing swatches of both types so they can feel and test the difference firsthand.

Don't guess. Test. Drape the lace over a form, stretch it, see how it recovers. Your due diligence in selection is what separates amateur results from professional execution.

Ready to specify the perfect lace for your next collection with confidence? Let's discuss your specific application challenges. Contact our Business Director, Elaine, at elaine@fumaoclothing.com. Share your designs, and let our technical team guide you to the optimal lace—stretch or non-stretch—that will bring your vision to life flawlessly.