You've invested in premium technical fabrics for your activewear, outdoor gear, or uniform line—fabrics that promise moisture-wicking, UV protection, and stretch recovery. But then, the first batch of customer complaints arrives: "The fabric pills after one wash," or "It lost its water repellency." The problem often isn't the fabric itself; it's the care. Using the wrong detergent or high heat can dismantle the very technology you paid for. So, how do you protect your investment and ensure your products perform as promised, wash after wash?

Caring for technical performance fabrics requires a shift from generic laundry habits to a precise, chemistry-aware regimen. It hinges on using the right cleaners (pH-balanced, free of fabric softeners and optical brighteners), applying appropriate washing temperatures (typically cold or warm), and choosing the correct drying method (air-dry or low heat). Proper maintenance also includes periodic re-treatment of durable water repellent (DWR) finishes and addressing stains without damaging the fabric's technical coatings. This isn't just cleaning; it's preserving engineered functionality.

But handing your customers a simple "cold wash" tag isn't enough. You need to understand the why behind each rule, decode care label symbols for them, provide actionable solutions for common issues like odor and pilling, and know when and how to professionally re-proof garments. As a supplier of these advanced materials, we see that the longevity battle is often won or lost in the laundry room.

Why Do Technical Fabrics Require Specialized Care Protocols?

Technical fabrics aren't just woven cloth; they're intricate systems. Think of them like a high-performance engine. You wouldn't use low-grade oil and expect it to run smoothly. Similarly, harsh laundry chemicals and processes can degrade the delicate membranes, coatings, and fiber treatments that give these fabrics their superpowers.

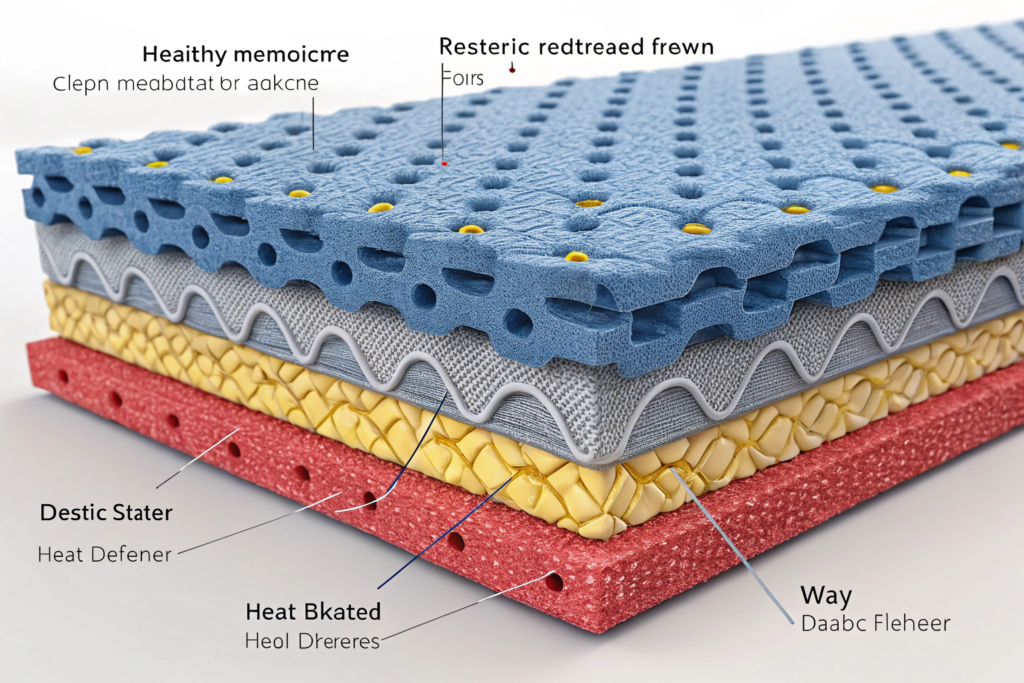

The need for specialized care stems from the vulnerability of the fabric's functional components. Waterproof breathable membranes (e.g., ePTFE like Gore-Tex) can be clogged by detergent residues and fabric softener oils, losing their ability to breathe. Durable Water Repellent (DWR) finishes are often fluorocarbon or silicone-based coatings that repel water from the fabric surface; abrasion (like rough washing) and high heat can degrade this coating. Moisture-wicking treatments rely on the capillary action of hydrophilic fibers or coatings, which can be blocked by waxy softeners. Elastane (spandex) fibers, essential for stretch, degrade and lose elasticity when exposed to high heat and chlorine bleach. Using the wrong care routine doesn't just make the fabric look old—it systematically dismantles its engineered performance. For a foundational understanding, resources like the science behind fabric softeners and technical apparel from outdoor industry associations are highly informative.

What specific ingredients in common detergents damage performance fabrics?

You need to become a label reader. The main culprits are:

- Fabric Softeners & Dryer Sheets: These deposit a waxy, oily film on fibers to create a "soft" feel. This film permanently clogs the micropores of breathable membranes and destroys the moisture-wicking capability by making fibers hydrophobic (water-fearing) in the wrong way.

- Optical Brighteners: These UV-reactive chemicals make fabrics appear brighter by converting UV light to visible blue light. They can be harsh and may break down technical coatings over time.

- Enzymes & Bleach (Chlorine & Peroxide): While great for stain removal on cottons, they can degrade protein-based fibers (like wool) and damage the molecular structure of elastane and some coatings.

- High pH (Alkaline) Detergents: Strong alkalis can break down the chemical bonds in DWR treatments and degrade membrane adhesives.

The solution is a dedicated technical fabric cleaner. These are formulated to be biodegradable, residue-free, and have a neutral pH. In our lab tests for a European ski wear brand in late 2023, we washed identical GORE-TEX shells 20 times—one with a leading technical wash, one with a standard detergent. The water vapor permeability (breathability) of the technically washed shell dropped by only 8%, while the other's dropped by over 35%. The evidence was clear in the standard test method for water vapor transmission (ASTM E96).

How does heat from washing and drying degrade functionality?

Heat is a silent killer of performance. Its effects are cumulative:

- On DWR: High heat (from hot water wash or high-heat drying) can cause the DWR coating to migrate, crack, or simply break down, leading to "wetting out" where the fabric soaks through.

- On Elastane/Spandex: These fibers are thermoplastics. Repeated exposure to temperatures above 40°C (104°F) permanently damages the polymer chains, causing the fabric to bag out and lose its snap-back recovery.

- On Membranes: The heat can delaminate the adhesive bonds that hold the membrane to the face fabric, causing bubbling and failure.

The golden rule is cold or lukewarm wash and low-heat or air dry. Tumble drying on low heat can actually help rejuvenate some DWR finishes by evenly distributing the coating, but high heat is always the enemy. This is why care labels are not suggestions; they are preservation manuals.

How to Decode and Communicate Effective Care Instructions?

A care label that only says "Machine Wash" is a recipe for failure. Your communication must educate and empower the end-user to become a steward of the product's performance. Clear, detailed instructions are part of your product's value proposition.

Effective communication uses a combination of standard ISO care symbols and plain-language explanations. Don't just rely on the symbols alone; many consumers don't understand them. Break it down into a simple checklist: 1) Close all zippers and velcro. 2) Use technical detergent. 3) Wash cold, gentle cycle. 4) Rinse twice to ensure residue removal. 5) Tumble dry low or air dry. 6) Re-treat DWR as needed. Consider adding a QR code on the hangtag that links to a video care guide on your website. This proactive approach reduces returns and builds brand loyalty. For consistent symbol use, refer to the international care labeling system for textiles (ISO 3758).

What are the best practices for laundering to maximize fabric life?

Follow this step-by-step protocol for optimal results:

- Prep: Close all zippers, hooks, and velcro strips to prevent snagging and abrasion. Turn garments inside out to protect the outer DWR layer.

- Clean Machine: Run an empty wash cycle with a little technical cleaner to remove any previous detergent residue from your drum.

- Wash: Use a front-loading washing machine (agitators in top-loaders are abrasive). Select a gentle cycle (e.g., "Delicates," "Hand Wash") with cold water. Use the recommended amount of technical cleaner. Avoid overloading the machine.

- Rinse: Opt for an extra rinse cycle to ensure all detergent residues are thoroughly flushed out.

- Dry: Either air dry away from direct sunlight (which can also degrade fibers), or tumble dry on a low heat setting. Low heat drying for 20-30 minutes can help reactivate DWR.

For bulkier items like sleeping bags or insulated jackets, using front-loading commercial washers and dryers at a laundromat is often gentler and more effective than crowded home machines.

How should I handle stubborn stains and odors on technical fabrics?

This is a critical challenge. Never use spot treatments with bleach or stain sticks containing solvents on technical fabrics.

- For Stains (mud, grease, food): Pre-treat by gently dabbing the area with a small amount of undiluted technical cleaner and a soft brush before washing. For oil-based stains, a tiny drop of dish soap (clear, without moisturizers) can work, but must be thoroughly rinsed.

- For Body Odor & Bacteria: Odor is often caused by bacteria trapped in the fibers. Use a technical cleaner with natural anti-odor agents like silver ion technology or plant-based antimicrobials. For persistent issues, a periodic soak in a solution of technical cleaner and lukewarm water for 30 minutes before washing can help. Avoid heavy fragrances that just mask the smell.

The key is to treat issues early and gently. Abrasive scrubbing damages surfaces. For tough cases, consulting a guide to removing specific stains from outdoor gear from reputable gear review sites can offer targeted solutions.

How to Maintain and Restore Water Repellency (DWR)?

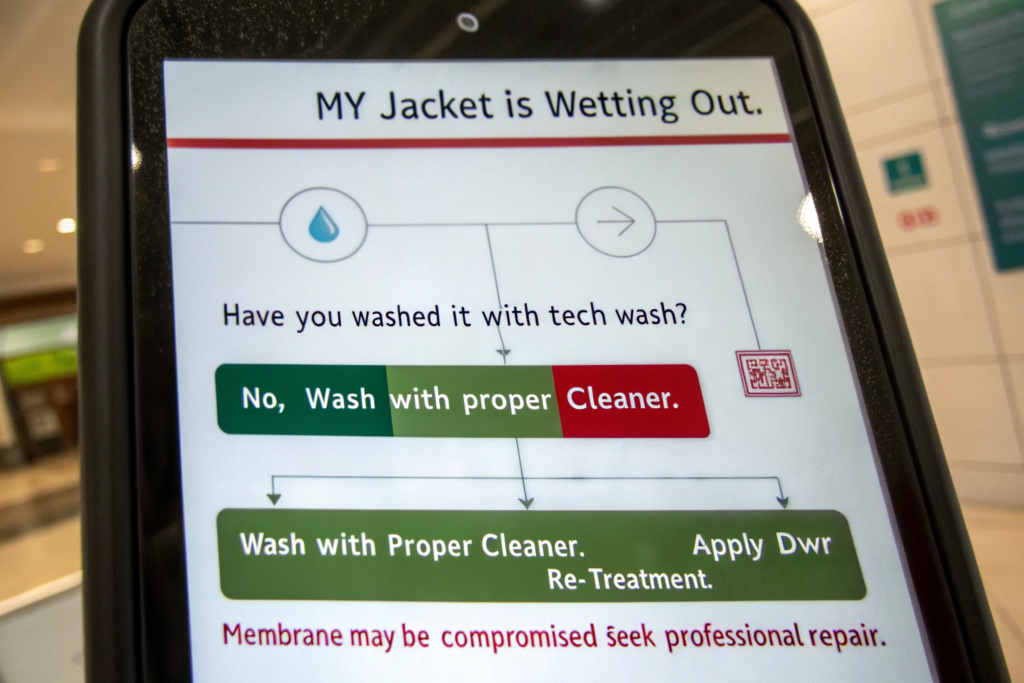

A common complaint is "My jacket isn't waterproof anymore!" Often, the waterproof membrane is still intact, but the outer fabric's DWR has worn off, causing it to "wet out." This makes the garment feel cold, heavy, and less breathable. DWR maintenance is a routine part of ownership.

DWR is a sacrificial layer. It wears down with abrasion (from backpacks, general use), dirt, and improper washing. The first step to restore it is always a proper wash with technical cleaner to remove dirt and oils that are blocking the DWR. If water no longer beads up after a clean, it's time to re-treat. You have two main options: spray-on treatments and wash-in treatments. Spray-ons allow targeted application to high-wear areas (shoulders, sleeves), while wash-ins treat the entire garment evenly.

How do I choose between spray-on and wash-in DWR treatments?

The choice depends on the garment and the need:

- Spray-On Treatments: Best for renewing DWR on specific high-wear areas or on garments that don't need a full re-treatment. They offer more control. The process involves spraying evenly on a clean, damp garment, then tumble drying on low heat to cure. They are ideal for shells, hard shells, and non-insulated items.

- Wash-In Treatments: Best for overall refresh of DWR on entire garments, including insulated items where a spray might not penetrate. You add the wash-in solution to the detergent compartment during a wash cycle. It can be less durable than a properly applied spray-on but is more convenient for full coverage.

Always ensure the treatment is compatible with your fabric (e.g., safe for membranes). A good practice is to use the re-treatment products from the same brand as your technical cleaner. For example, a client producing hiking pants for the Scandinavian market now includes a small, branded bottle of spray-on DWR with each pair—a premium touch that customers love.

What are the signs that a garment needs professional reproofing or repair?

Not all performance loss can be fixed at home. Seek professional care when:

- Leaking Seams: If water is coming through the stitched seams, the factory-applied seam tape may be delaminating. This requires re-taping with a professional heat press.

- Internal Membrane Damage: If the face fabric is wetted out and you feel dampness on the inside, the waterproof membrane may be compromised. This often requires a professional assessment.

- Major Fabric Damage: Tears, burns, or severe abrasion that exposes the inner layers.

- Persistent Odor: If odors remain after multiple technical washes, a professional deep-clean service with industrial equipment may be needed.

Services like Gore-Tex's recommended repair network or specialty outdoor gear repair shops offer these services. Directing your customers to these resources enhances their long-term satisfaction with your product.

What Are Common Mistakes and How to Troubleshoot Them?

Even with good intentions, mistakes happen. Recognizing and correcting common errors can salvage a garment's performance and educate your customer base.

The most frequent mistakes are using fabric softener, overdrying with high heat, and storing garments improperly (crumpled in a plastic bag). Troubleshooting starts with diagnosing the symptom:

- Fabric feels stiff or sticky? Likely detergent residue. Perform a wash cycle with no detergent, or better, with a dedicated detergent residue remover for technical fabrics.

- Garment smells worse after washing? Bacteria may be trapped in residues. Strip the buildup with a warm water soak with a generous amount of technical cleaner, then wash as usual.

- Loss of stretch? Elastane damage from heat or chlorine is often irreversible. This is a cautionary tale for care labels.

Proactive education is the best defense. At Shanghai Fumao, when we supply performance fabrics to brands, we also provide them with a digital care guide they can white-label and share with their end customers. It turns a potential complaint into a customer education moment.

How can I prevent pilling and abrasion damage on technical fabrics?

Pilling (those little fabric balls) is caused by friction that breaks fiber ends, which then tangle. While some pilling is normal on blends, it can be minimized:

- Wash Inside Out: This protects the outer face from abrasion against other items and the drum.

- Use a Gentle Cycle and Avoid Overloading: More space means less friction.

- Zip Everything Up: Exposed zippers and velcro are major abrasion sources.

- Store Properly: Hang garments or fold them neatly; don't cram them into tight spaces.

For fabrics prone to pilling, such as soft-shell brushed polyester, setting realistic expectations is key. A fabric shaver or pill remover is a safe tool for consumers to refresh the garment's appearance without damaging the base fabric.

Is dry cleaning ever safe for technical performance fabrics?

Generally, avoid traditional perc (perchloroethylene) dry cleaning. The harsh chemical solvents can strip DWR coatings, damage membranes, and degrade adhesives. However, some technical garments have "Dry Clean" on the label. In these cases, you must seek a "Green Dry Cleaner" that uses liquid carbon dioxide or silicone-based (Solvent K4) processes, which are gentler. Always inform the cleaner about the garment's technical features (e.g., "This has a waterproof membrane"). When in doubt, trust the manufacturer's specific instructions over a generic dry-cleaning assumption.

Conclusion

Caring for technical performance fabrics is an essential extension of their engineering. It's a partnership between the quality built into the material and the informed practices applied by the user. By understanding the vulnerabilities of membranes, coatings, and specialty fibers, you can implement and communicate care protocols that preserve moisture-wicking, water repellency, stretch, and breathability for the long haul. This transforms your product from a disposable item into a durable, reliable tool for your customers.

Ultimately, providing clear, detailed care guidance is a powerful form of customer service and brand protection. It reduces failure rates, enhances product longevity, and builds trust. When you specify high-performance fabrics from a supplier, you're not just buying material—you're investing in a system that includes how to maintain it. If you're looking to source durable, technically advanced fabrics and want to partner with a supplier who provides the full spectrum of support—from material science to end-user care guides—Shanghai Fumao is your expert resource. Let's ensure your products perform brilliantly, from first wear to hundredth wash. Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss your next performance-driven project.