When you need a fabric that can withstand the weight of winter winds or the daily wear and tear of furniture, choosing the wrong material is a costly mistake. You need substance, durability, and the right aesthetic—but with so many "heavy-duty" options on the market, how do you pick the one that truly balances performance with practicality? Let's dive into the world of heavyweight fabrics and cut through the bulk.

The best heavyweight fabrics for coats and upholstery are those that offer an optimal blend of durability, structure, comfort, and ease of maintenance. For coats, top contenders include Melton Wool, Boiled Wool, and heavy Cotton Canvas for structure and warmth; for upholstery, performance-driven fabrics like Crypton, Sunbrella, and heavy-duty Velvet lead the pack. The "best" choice ultimately depends on the specific end-use, desired aesthetics, and required technical performance like abrasion resistance or water repellency.

However, simply knowing the names isn't enough. You need to understand the "why" behind each fabric's strength, how their construction dictates their function, the critical performance specs you must demand from suppliers, and the smart sourcing strategies to get the best value without compromising on quality. As a supplier in Keqiao, I've sourced and developed these fabrics for global brands, and the devil is always in the technical details.

What Defines a "Heavyweight" Fabric and Why Does It Matter?

In our industry, "heavyweight" isn't just a feel; it's a precise measurement that dictates capability. Getting this specification wrong means your coat might lack structure or your sofa might sag in a year. Weight is the foundational spec that informs durability, drape, insulation, and cost.

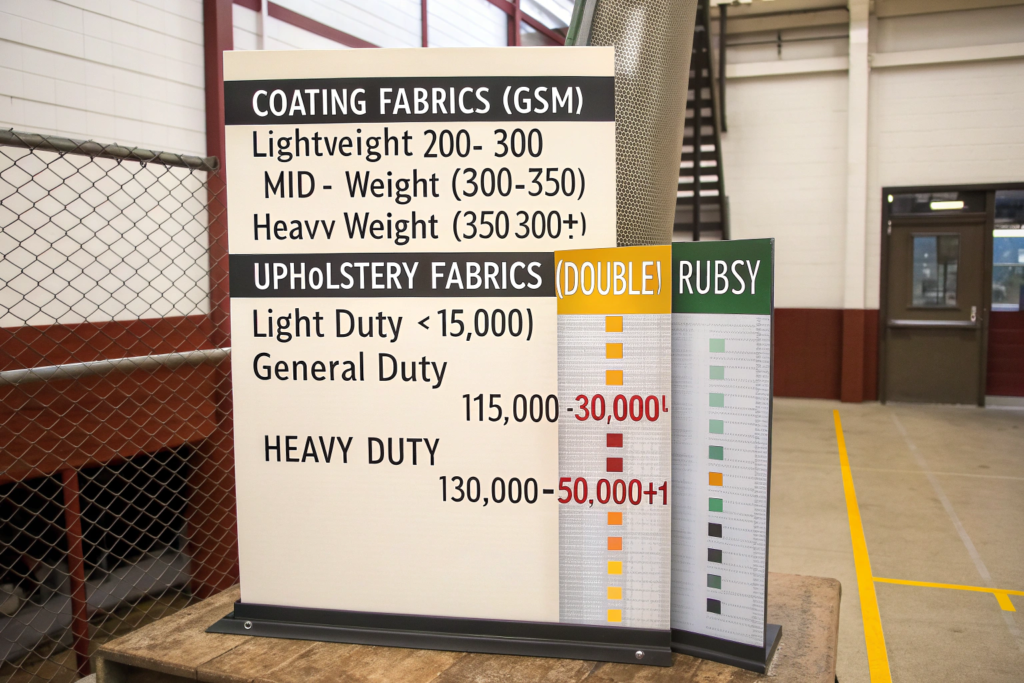

A fabric is classified as heavyweight primarily by its grams per square meter (GSM) or ounces per square yard (oz/yd²). For coats, heavyweight typically starts at around 350 GSM (10 oz/yd²) and can go up to 600+ GSM (18+ oz/yd²) for extreme outerwear. For upholstery, the benchmark is the Wyzenbeek or Martindale abrasion test, with heavyweight duty fabrics often rated for 50,000+ double rubs, usually correlating with fabrics over 350 GSM. The weight comes from thicker yarns, tighter weaves (like a tight 2x2 twill), or additional processes like milling (felting) or coating. This mass directly translates to wind resistance, thermal insulation, and the ability to hold a tailored shape or support constant weight.

How does fabric weight correlate with durability and warmth?

The relationship is direct, but not perfectly linear. Think of it like the thickness of a wall. A higher GSM fabric has more fiber mass per unit area, creating a denser barrier. For warmth, this mass traps more insulating air. For durability, the thicker yarns and denser construction have more material to sacrifice before showing wear. However, the type of fiber is crucial. A 400 GSM wool Melton will be warmer and more resilient to pilling than a 400 GSM polyester canvas, but the canvas might be more resistant to abrasion and water. A key spec to ask for is the fabric's pilling resistance test result (ASTM D4970), especially for wool and wool-blend coatings. For upholstery, the abrasion resistance rating (ASTM D4157) is non-negotiable. In 2023, a UK furniture brand switched to a 420 GSM polyester-wool blend from us for their signature armchair, increasing their Martindale rating from 40,000 to 75,000 double rubs, which allowed them to extend their warranty by 2 years—a powerful marketing point.

What are the trade-offs of using very heavy fabrics?

Heavier isn't always better. The trade-offs are significant:

- Cost: More raw material = higher cost.

- Hand and Drape: Very heavy fabrics can be stiff, making them harder to tailor for sleek coat designs or to upholster on curved furniture frames.

- Comfort: A coat made from an extremely heavy fabric can be cumbersome to wear.

- Production Challenges: Heavy fabrics demand heavier-duty sewing machines and needles, potentially increasing manufacturing costs and limiting the factories you can use.

The art is finding the minimum effective weight for your application. A heavy winter parka might need 500 GSM, while a structured blazer coat might achieve its silhouette perfectly with a 380 GSM fabric. Always request hand-feel samples and a physical weight swatch before bulk ordering. Consulting a guide to fabric weight and garment drape for designers can help bridge technical specs with creative vision.

Which Heavyweight Fabrics Are Best for Winter Coats and Jackets?

For coats, the fabric must be a shield. It needs to provide warmth, block wind, retain its shape through seasons, and look good doing it. The champions here are often natural fiber-based or high-tech blends that mimic and enhance nature's best properties.

The top performers combine density, fiber resilience, and often a specialized finish. Melton Wool is the undisputed king for structured overcoats and peacoats—it's heavily milled (felted), incredibly dense, wind-resistant, and has a beautiful smooth face. Boiled Wool is a knit that's been agitated to shrink and felt it, creating an ultra-warm, stretchy, and casual fabric perfect for jackets. For workwear or tech-style jackets, Heavyweight Cotton Canvas or Duck (often around 12-16 oz) provides incredible abrasion resistance and takes waxed or PU coatings superbly for water resistance. Today, advanced recycled polyester fleece and nylon taslan fabrics with durable water repellent (DWR) finishes are leaders in performance outerwear, offering lightweight warmth and extreme weather protection at a heavier weight class.

What makes Melton Wool the gold standard for overcoats?

Melton is a masterpiece of traditional fabric engineering. It's a woolen fabric (using carded, not combed, yarns for loft) that undergoes an aggressive milling or felting process. This process shrinks the fabric drastically, matting the fibers together to create an almost felt-like surface that is:

- Nearly Windproof: The dense, matted fibers leave no gaps for air to penetrate.

- Highly Durable: The felled structure resists tearing and abrasion.

- Shape Holding: It has a firm body that maintains a tailor's pressed seams and drape beautifully.

- Low Maintenance: It's naturally wrinkle-resistant and doesn't shine easily.

The key to quality Melton is the wool grade and the milling precision. At Shanghai Fumao, we source specific Australian or New Zealand wools for our Melton productions to ensure consistency. A common mistake is using a Melton that's too light; a proper overcoat Melton should be a minimum of 550-600 GSM. For brands new to this, understanding the process of milling wool for heavyweight fabrics is essential to evaluate suppliers properly.

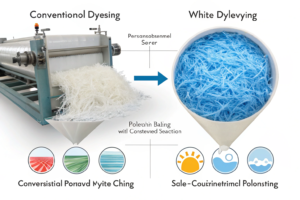

How are modern technical fabrics competing with traditional wools?

They compete by solving specific weaknesses. Modern synthetics offer unparalleled consistency and targeted performance at a often lower cost. For instance:

- Water Resistance: A DWR finish on a nylon taslan is far more effective and durable than the natural water-shedding of wool.

- Weight-to-Warmth Ratio: High-pile recycled polyester fleeces or primaloft insulation provide incredible warmth at a fraction of the weight of a heavy wool.

- Functionality: Fabrics with built-in stretch (using spandex) enhance mobility without compromising the heavy-duty feel.

The trend is toward blends. We are seeing huge demand for wool-nylon blends (e.g., 70% wool / 30% nylon) for coats. The wool provides warmth and aesthetics, the nylon adds tensile strength and abrasion resistance. In 2024 Q1, we developed a 480 GSM recycled wool and recycled polyester blend for a Scandinavian brand that wanted the classic wool look with enhanced durability and a strong sustainability story—it became their best-selling coat fabric. Resources like comparative analysis of natural vs. synthetic insulation materials are valuable for making these technical choices.

Which Heavyweight Fabrics Are Best for High-Traffic Upholstery?

Upholstery fabric is a battle zone. It fights against sunlight, spills, friction, and pets. The best fabrics here are engineered for war, not just weight. They prioritize cleanability, fade resistance, and phenomenal abrasion numbers alongside their heft.

Performance fabrics with integrated technology lead the commercial and high-end residential markets. Crypton is a superstar—it’s not just a fabric, but a patented system where the yarn, backing, and finish work together to repel stains, moisture, and bacteria, all while remaining breathable and achieving over 100,000 double rubs. Sunbrella (acrylic) is the outdoor/indoor champion, famous for its colorfastness against UV rays and mildew resistance. For a luxurious heavy-duty option, heavyweight contract velvet (often a polyester or nylon blend with a dense, low-pile construction) can offer both elegance and 50,000+ double rubs. Don't overlook textured synthetic weaves like olefin or solution-dyed polyester in a heavy weight—they are workhorses for healthcare and hospitality.

What does a high "double rub" count really mean for my furniture?

The Martindale or Wyzenbeek abrasion test is the industry's standardized way to predict fabric life on furniture. It mechanically rubs fabric until noticeable wear (yarn break) occurs. The count is the number of cycles it withstands.

- 15,000-25,000 double rubs: Suitable for light residential use (occasional sitting).

- 25,000-35,000 double rubs: Good for general family use.

- 35,000-50,000+ double rubs: Heavy duty, suitable for commercial offices, hotels, or high-use family rooms.

A count over 50,000 is often required for contract/commercial specifications. However, the test is just one indicator. A fabric with a high rub count but poor colorfastness to crocking (rubbing off dye) will look terrible even if it doesn't wear through. Always ask for a full test report from an accredited lab like SGS or ITS. We provide these for all our upholstery fabrics, and it saves clients from costly returns. For a deeper dive, the International Association of Certified Home Inspectors' guide to upholstery fabric testing standards explains these specs in a consumer-friendly way.

How do performance finishes like Crypton work, and are they worth it?

They work by creating a multi-layered defense system, and for the right application, they are absolutely worth the premium. Crypton, for example, isn't just a topical spray. The treatment is embedded at the fiber level and includes a moisture barrier backing. This creates:

- Stain & Moisture Resistance: Spills bead up and can be blotted away.

- Antimicrobial Protection: Inhibits odor-causing bacteria and mold.

- Breathability: Unlike vinyl, it doesn't feel sticky or plastic.

The value is in reduced maintenance costs, longer lifespan, and the ability to use lighter-colored fabrics without panic. For a hotel, restaurant, or a family with young children, this is a game-changer. When sourcing, ensure the supplier provides the authentic Crypton hangtag and certification—there are many imitations. The technology is so in-demand that learning about alternative stain-resistant fabric technologies for budget-conscious projects can also be a smart move for value lines.

How to Source Heavyweight Fabrics Smartly from China?

Sourcing heavyweight fabrics has its own set of logistical and quality challenges. The weight impacts shipping costs, the technical specs require rigorous testing, and the premium nature means you can't afford quality deviations. Smart sourcing is about leveraging expertise and local networks.

The strategy hinges on three pillars: technical validation, supply chain transparency, and logistical foresight. You must partner with suppliers who have proven expertise in these specific fabric categories, not just general fabric traders. They should understand the nuances of milling wool, applying durable coatings, or weaving tight, high-density constructions. Given the higher material cost, in-process quality control at the weaving and finishing stages is critical to catch defects early.

What quality checks are non-negotiable for heavyweight fabrics?

Your inspection protocol must be stricter than for lightweight fabrics. Essential checks include:

- Weight Verification: Randomly check the GSM/oz of bulk rolls against the approved sample. A 10% variance is unacceptable.

- Tensile and Tear Strength Tests (ASTM D5034/D5587): For upholstery, this predicts how well it will hold up to stretching and stress on frames.

- Seam Slippage Test: For coat fabrics, this ensures the seams won't pull apart under the weight and stress of the garment.

- Visual Inspection for Weaving Defects: Heavy fabrics can hide thick/thin yarns, weaving stops, or dye streaks. A professional fabric inspection machine process is ideal.

We learned this the hard way years ago with a 450 GSM cotton canvas order. We skipped a pre-shipment tear test, and the client's factory found the fabric ripped too easily during sewing. The entire batch was rejected. Now, our in-house QC team runs these tests as standard, and we share the reports. It builds immense trust.

How does fabric weight impact shipping costs and lead times?

Significantly. Heavy fabrics mean higher shipping costs by both sea (you fit fewer meters in a container by weight) and air (prohibitively expensive for bulk). This must be factored into your cost calculation upfront. For lead times, the production of heavyweight fabrics itself is often slower—looms run slower with thicker yarns, and finishing processes like milling or coating add extra steps. When planning, add a 15-20% buffer to the standard lead time for heavyweights. Also, discuss packaging for heavy fabric rolls with your supplier to prevent crushing during transit, which can create permanent creases. A reliable partner like Shanghai Fumao, based in the Keqiao cluster, can consolidate your heavy fabric order with others or optimize container loading to manage these costs and complexities for you.

Conclusion

Choosing the best heavyweight fabric is a strategic decision that blends art and science. For coats, the timeless density of Melton Wool and the innovative performance of technical blends offer solutions for every style and function. For upholstery, engineered fabrics like Crypton and Sunbrella redefine durability, marrying heavy-duty construction with smart technology for real-world living. The common thread is the necessity for precise specifications—GSM, abrasion counts, and certified test reports—that move you beyond subjective feel to guaranteed performance.

Ultimately, success lies in partnering with a source that doesn't just sell you fabric, but understands the engineering behind it. You need a supplier who can guide you to the optimal weight for your design, validate its durability with hard data, and navigate the logistical realities of sourcing substantial materials globally. If you're looking to develop a coat line that stands the test of time or furnish a space that combines luxury with resilience, having the right heavyweight foundation is everything. Let's build that foundation together. For expert sourcing of heavyweight Melton wools, performance canvases, or certified contract upholstery fabrics, contact our Business Director, Elaine, at Shanghai Fumao: elaine@fumaoclothing.com. Let's make something that lasts.