Your swimwear line is only as good as its stretch. You've seen it happen: a bikini that loses its shape after a few wears, a one-piece that sags after swimming. The market is unforgiving. Customers expect swimwear to look pristine, move with them, and bounce back season after season. The secret isn't just in the design—it's in the very fibers and construction of the fabric. As a fabric supplier rooted in Keqiao for over two decades, I can tell you that sourcing the right high-elasticity fabric is a technical dance, not a guessing game. It's about understanding the interplay between fiber, knit, and finish to achieve that perfect, lasting snap-back.

So, how do you source fabric with superior elastic recovery for swimwear? You need to look beyond just "spandex content." True recovery is a result of three pillars: selecting the right high-performance synthetic fibers (like premium nylon-polyester-spandex blends), specifying an advanced knitting construction (such as circular knits with specific tension settings), and demanding rigorous post-production testing (including multiple cycles of stretch and recovery under simulated conditions). Missing any one of these can lead to garment failure.

Let's break down the industry jargon and get to the practical, actionable knowledge. I'll share not just the "what," but the "how" and "why" from the factory floor perspective. We'll navigate the common pitfalls, understand the testing that matters, and learn how to communicate your needs effectively to a supplier to ensure your swimwear collections perform as stunningly as they look.

What is Elastic Recovery and Why is it Non-Negotiable for Swimwear?

Imagine putting on a swimsuit that fits perfectly on the first wear. Then, after a day at the beach, it feels a bit looser. By the end of the season, it's noticeably baggy. That's a failure in elastic recovery. Simply put, elastic recovery is a fabric's ability to return to its original shape and length after being stretched. For swimwear, this isn't a luxury; it's the core of garment integrity, customer satisfaction, and brand reputation. A suit with poor recovery will lose its supportive fit, cause discomfort, and look worn out quickly, leading to returns and negative reviews.

How Do You Define and Measure "Good" Recovery in a Fabric?

It's not a vague concept; it's quantifiable. In our CNAS-accredited lab, we measure it primarily through a Cyclic Stretch Test. A fabric sample is clamped, stretched to a specified percentage (often 50-80% for swimwear), held, released, and allowed to recover. This cycle is repeated, typically 100 times or more. The key metric is the percentage of recovery after the final cycle. Premium swimwear fabric should recover over 95% of its original length. Anything below 90% is a red flag. Another critical test is tension decay, which measures how much holding force the fabric loses after repeated stretching—a sign it will become less supportive.

You can't judge this by hand-feel alone. Always request a test report from an accredited lab (like SGS, ITS, or a supplier's own certified lab). Look for standards like ASTM D2594 or ISO 20932-1. A trustworthy supplier like Shanghai Fumao will provide these data points upfront. For instance, in a 2023 project for a Miami-based activewear brand, we provided fabric with a documented 97.5% recovery after 100 cycles at 80% extension, which became their key selling point.

What Happens to Swimwear When Elastic Recovery Fails?

The failure modes are specific and costly. The most common is bagging out at the knees and seat, where the fabric simply doesn't snap back from a seated or bent position. Next is neckline and leg opening gape, where edges curl and won't hug the body. There's also color distortion; as the fabric permanently deforms, the dyed fibers shift, causing uneven sheen or light patches. Finally, seam failure occurs because the constantly strained fabric puts excessive stress on stitches.

I recall a case from a French startup in June 2022. They sourced a cheaper 15% spandex blend from another vendor. The initial samples felt great. But after our routine pre-production testing, we found its recovery rate dropped to 88% after just 50 wet-and-dry cycles (simulating ocean and pool use). We advised them of the risk. They proceeded, and six months later faced a 12% return rate primarily due to sagging. They then came to us to redevelop the fabric, where we adjusted the nylon filament type and knitting tension to solve the issue. This is why understanding how to interpret swimwear fabric quality test reports is a crucial skill for any brand.

Which Fiber Blends Deliver the Best Stretch and Recovery for Water?

Not all stretch is created equal. The magic for swimwear happens with synthetic fibers. Natural fibers like cotton have no place here—they absorb water and lose all shape. The championship team is a blend of Nylon (Polyamide) and Spandex (Elastane/Lycra), sometimes with Polyester in the mix. Nylon provides excellent strength, abrasion resistance, and a soft, color-rich hand-feel. Spandex provides the stretch—typically 15-25% content is standard. Polyester adds durability, chlorine resistance, and faster drying, but can feel less soft.

The real art is in the fiber specifications within these categories. For top-tier recovery, you need high-tenacity nylon 6,6 filaments and multi-filament covered spandex. The way the spandex is "covered" or wrapped with nylon during yarn production protects it from chlorine, oils, and heat, drastically extending the garment's life and recovery. A common mistake is focusing only on spandex percentage. A fabric with 20% low-quality, uncovered spandex will fail faster than one with 15% premium, covered spandex.

Nylon vs. Polyester Blends: Which is Right for Your Line?

This is a fundamental choice that impacts feel, performance, and cost.

| Property | Nylon-Dominant Blend (e.g., 80% Nylon, 20% Spandex) | Polyester-Dominant Blend (e.g., 80% Polyester, 20% Spandex) |

|---|---|---|

| Hand Feel | Softer, smoother, more luxurious. | Stronger, slightly crisper, can be engineered to feel soft. |

| Chlorine Resistance | Good, but can degrade over time with high chlorine exposure. | Excellent. Inherently more resistant to chlorine damage. |

| Color Vibrancy | Exceptional. Takes dye beautifully for deep, rich colors. | Very good, but often requires different dyeing techniques. |

| Drying Speed | Fast. | Very fast. |

| Durability/Abasion | Excellent. | Superior. Highly resistant to wear from pool concrete. |

| Cost | Generally higher. | Generally more economical. |

My advice? For luxury fashion swimwear where feel and color are paramount, choose nylon. For performance swimwear, training suits, or kids' swimwear that needs to withstand heavy chlorine and abuse, choose polyester. At Shanghai Fumao, we often engineer blends of all three (e.g., 50% Nylon, 30% Polyester, 20% Spandex) to balance these properties. Our guide to choosing between recycled nylon and polyester for eco-swimwear dives deeper into sustainable options.

How Does "Creora®" or "Lycra®" Spandex Make a Difference?

Branded spandex like Hyosung's Creora® or The LYCRA Company's Lycra® are not marketing gimmicks. They represent a quality standard and specific technologies. These manufacturers produce consistent, high-performance elastane fibers with better initial modulus (how much force it takes to start stretching) and recovery power. They also offer specialized variants:

- Lycra® Sport: Designed for high support and lasting shape.

- Creora® Eco-Soft: Focuses on sustainable production and a soft hand-feel.

- Chlorine-Resistant Types: Chemically modified to withstand pool chemicals.

Specifying a branded spandex gives you a benchmark for quality. It tells your supplier you understand the raw material chain. However, it does come at a premium. For many brands, a non-branded but high-quality covered spandex from a reputable yarn spinner is a perfectly viable and cost-effective option. The key is to ask your supplier for the yarn origin and its technical data sheet. Don't just accept "we use spandex." (Here's a tip from our production floor: the feel of a covered spandex yarn is much smoother and more uniform than a bare one).

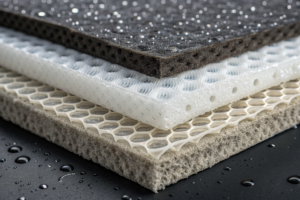

Beyond Fiber: How Does Knitting Construction Lock in Recovery?

The best yarn can be ruined by poor construction. The knitting process is where recovery is engineered into the fabric. For swimwear, circular knitting on fine-gauge machines (like 28-gauge or 40-gauge) is standard. The gauge determines how fine and dense the knit is—higher number means finer, smoother fabric. The stitch structure is vital. A plain single jersey is basic and can curl. Double-knit constructions (like interlock or ponte di roma) are more stable and recover better because they are essentially two layers of fabric knit together.

The machine's tension settings during knitting are the secret sauce. Consistent, precise tension ensures every loop of spandex is activated uniformly. If tension is too high, the fabric can be over-stretched and lose recovery power. If it's too low, the fabric will be loose. Our technicians monitor this in real-time. Furthermore, plating is a technique where two different yarns (e.g., nylon and spandex) are fed into the same needle, placing one predominantly on the fabric face and the other on the back. This optimizes both aesthetics and performance.

Why Does Fabric "Weight" and "Gauge" Matter for Longevity?

These are your first tangible specs to discuss with a supplier.

- Fabric Weight: Measured in GSM (grams per square meter). Swimwear typically ranges from 180 GSM (lightweight, for minimal coverage suits) to 230+ GSM (for supportive, structured one-pieces or sportswear). Heavier weight generally correlates with better opacity, support, and often better recovery due to higher yarn density.

- Machine Gauge: Indicates the number of needles per inch on the circular machine. 28-gauge is common for standard swimwear, producing a good balance of durability and feel. 40-gauge produces a very fine, silky, lightweight fabric used in high-end fashion lines.

A 200 GSM fabric from a 28-gauge machine will have a different structure and recovery profile than a 200 GSM fabric from a 40-gauge machine. Always request swatches with full specifications—weight, gauge, fiber content, and width. A 2023 order for a UK brand required a 210 GSM, 40-gauge double-knit fabric with 78% Nylon, 22% Lycra® for a line of long-torso one-pieces. The double-knit construction was crucial to prevent sideways distortion and maintain vertical recovery.

How Can "Four-Way Stretch" Be a Misleading Term?

Many buyers ask for "four-way stretch," thinking it's superior. Technically, most knitted swimwear fabrics stretch in both directions (width and length) due to their looped structure. The more critical property is controlled stretch or power. You want the fabric to have a firm, supportive stretch in the width (for hugging the body) and a more forgiving, comfortable stretch in the length (for movement). This is engineered through the knit structure and yarn tension, not by a generic "four-way" label. Ask instead: "What is the stretch and recovery percentage in both the course (length) and wale (width) directions?" A professional supplier will have this data.

For a deep dive on engineering fabric construction, this feature on knit fabric construction for performance apparel is an excellent resource from an industry publication.

How to Vet a Supplier's True Capability in Delivering Recovery?

This is where the rubber meets the road. A supplier might have beautiful swatches, but can they deliver consistent recovery in bulk over 10,000 meters? You vet them through technical dialogue, sample validation, and audit trails. Start by asking specific questions: "What is your standard recovery test method and acceptable minimum for swimwear?" "Can you provide a third-party test report for a similar fabric you've produced?" "How do you control knitting tension batch-to-batch?"

The next step is a development sample. Pay for this step—it's an investment. Specify your exact requirements: fiber brands, weight, gauge, width, and key performance tests. When you receive the development sample, have it independently tested yourself. The $200-300 cost can save you from a $20,000 disaster. Look for consistency: does the recovery data match what the supplier promised?

What Factory Audits and Certifications Should You Look For?

Paperwork matters. A factory with a CNAS-accredited in-house lab (like ours) invests in quality control. Certifications like OEKO-TEX® STANDARD 100 (for safety) and GRS (for recycled content) show a systematic approach. But don't just collect certificates; understand their scope. Ask for a virtual tour of the knitting and lab areas. During a tour, you can ask to see the tension monitors on the knitting machines or the cyclic testers in the lab. A confident supplier will show you.

Shanghai Fumao's advantage is vertical coordination. We control the knitting in our own factory and have long-term, aligned partnerships with dyeing and finishing units. This means we can trace any recovery issue back to the exact knitting batch, dyeing lot, or heat-setting temperature. In contrast, a pure trading company often cannot pinpoint or solve these technical root causes. For insights into auditing Asian supply chains, this article on conducting effective factory visits in Asia offers practical advice.

How to Structure Your Sourcing Timeline Around Production Peaks?

Your perfect fabric means nothing if it arrives late. China's manufacturing calendar is real. For swimwear targeting a Spring/Summer launch, you must work backward.

- Key Periods: The August-October period is peak production for holiday goods. Adding 1-2 weeks to timelines is wise. Chinese New Year (3-4 week shutdown, Jan/Feb) is critical. A European client of ours now finalizes all pre-production 6 weeks before CNY, ensuring production starts the week factories reopen.

- Ideal Sourcing Window: The slower periods of June-July or November-December offer timeline advantages. This is the best time for new fabric development and sampling with less factory congestion.

- Pro Tip: Place your bulk fabric order before the factory holiday rush. The fabric can be produced and stocked, ready for cutting and sewing immediately after the holidays. This simple planning step can save you 4-5 weeks.

Plan your fabric sourcing and development cycle to avoid these rushes. A smart timeline is your silent competitive advantage, ensuring you have the time for proper sampling and testing without rushing to market with a compromised product.

Conclusion

Sourcing swimwear fabric with exceptional elastic recovery is a detailed, technical process that separates successful brands from the rest. It requires a deep understanding of the three core pillars: the science of fiber blends, the engineering of knit construction, and the rigor of quantitative testing. It's not enough to simply find a fabric that stretches; you must find one that remembers its shape, trip after trip, wash after wash.

Remember, your supplier should be a technical partner, not just a vendor. They should speak the language of recovery percentages, cyclic testing, and gauge settings. They should provide data, not just promises. By asking the right questions, demanding verified samples, and planning your timeline strategically, you can secure the foundation your swimwear line needs to thrive in a competitive market.

If you're looking to develop or source high-performance swimwear fabrics with guaranteed elastic recovery, let's talk. Our team, from the knitting floor to the lab, is built to solve these precise challenges. Reach out to our Business Director, Elaine, to discuss your next collection. She can connect you with our technical R&D team for a consultation. Email Elaine at elaine@fumaoclothing.com. Let's create swimwear that lasts.