You've seen those stunning, all-over-print sportswear kits, vibrant custom flags, and photorealistic soft signage. The magic behind them is dye sublimation printing—a process that bonds dye directly into a fabric's fibers, creating brilliant, permanent prints. But here's the frustrating part many designers and brands discover too late: if you choose the wrong fabric, your vibrant design comes out dull, blurry, or washes away. I've spent 20 years in the textile hub of Keqiao, and I can tell you that the success of your sublimation project is 80% determined by the base fabric you choose before a single drop of ink is used.

The best fabrics for dye sublimation are those with a high synthetic fiber content—specifically polyester—and a light-colored, tightly woven or knitted surface that has been specially prepared to accept the dye. Polyester is the undisputed champion because the sublimation dyes chemically bond with its polymer chains at a molecular level. However, not all "polyester" fabrics are created equal. The specific construction, weight, finish, and even the whiteness of the base cloth make all the difference between an okay print and an extraordinary one.

Choosing incorrectly leads to heartbreak: muted colors, poor detail, stiff hand feel, and prints that crack or fade. It's not just about the fabric being "printable"; it's about it being optimized for sublimation to give you the best color gamut, sharpness, and durability your project deserves. Let's dive into the specifics so you can source with confidence.

Why is Polyester the Undisputed King for Sublimation?

The science is simple but non-negotiable. Dye sublimation inks are formulated as disperse dyes. When heated to a high temperature (around 200°C/390°F), these dyes turn into a gas. Polyester fibers, being thermoplastic and synthetic, open up at these high temperatures. The gaseous dye penetrates the fiber, and as the fabric cools, the fibers close, trapping the dye inside the fiber permanently. This is why sublimated prints are so durable—the color is part of the fiber, not sitting on top like in direct-to-garment printing.

In contrast, natural fibers like cotton or silk don't have this polymer structure. The dye mostly sits on the surface, resulting in washed-out colors, a stiff hand, and poor wash fastness. A common industry specification we use at Shanghai Fumao for premium sublimation is 100% filament polyester with a bright, bleached white base. The filament yarns create a smooth surface for exceptional detail, and the bright white base allows for the truest, most vibrant color reproduction.

Can You Sublimate on Blends or "Subli-Finished" Cotton?

This is a major point of confusion. The answer is nuanced:

- Polyester Blends (e.g., 50/50 Poly-Cotton): You can sublimate, but you get a vintage or distressed look. The dye only bonds to the polyester fibers, leaving the cotton fibers white. This creates a softer, lighter print. It's a specific aesthetic, not a failure.

- "Sublimation-Ready" or "Subli-Finished" Cotton: This is a special treatment where a polymer coating is applied to the cotton fabric. While it allows for brighter prints than untreated cotton, it often results in a stiffer hand feel and the print can eventually crack or peel with repeated washing.

A practical case from last year: A U.S.-based e-sports apparel brand wanted ultra-vibrant jerseys. They initially sampled a 85/15 Poly-Cotton blend for comfort, but the prints lacked "pop." We guided them to a 100% micro-polyester interlock knit (180 GSM). The difference was night and day—the colors were electrifying, and the fabric maintained excellent moisture-wicking and stretch.

What are the Key Specifications to Look for in a Sublimation Polyester?

Don't just order "white polyester." You need to specify:

- Fiber Type: Filament polyester is superior to staple polyester for print sharpness.

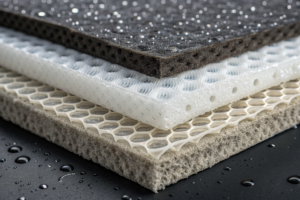

- Fabric Weight (GSM): Lighter fabrics (100-130 GSM) for flags. Medium weight (150-200 GSM) for activewear.

- Weave/Knit: A tight, plain weave or a smooth interlock knit provides the best "canvas."

- Whiteness & Brightness: Request a high-whiteness, optically brightened base.

For a deep technical dive, Sawgrass Technologies' guide to choosing sublimation fabrics provides excellent, vendor-neutral education.

Which Fabric Constructions Work Best for Different Products?

The "best" fabric changes based on the end product. A fabric perfect for a stretchy legging will fail as a rigid flag.

Here’s a quick-reference table based on thousands of projects:

| Product Category | Recommended Fabric Type | Key Characteristics & Why It Works |

|---|---|---|

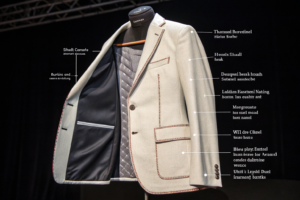

| Sportswear / Activewear | Polyester Interlock Knit, Microfiber Jersey | Stretch recovery, moisture-wicking, smooth face for sharp prints. |

| Fashion Apparel | Polyester Chiffon, Satin, Crepe | Drape, sheen, and texture suitable for dresses and blouses. |

| Soft Signage / Flags | Polyester Sheer (Flag Banner Fabric) | Lightweight for easy hanging, good color vibrancy for viewing distance. |

| Home Textiles | Polyester Canvas, Twill | Heavier weight for durability, tight weave to prevent bleed. |

What Makes a Knit Fabric Ideal for Sublimated Apparel?

For apparel, especially activewear, the fabric must perform.

- Stretch and Recovery: The knit construction provides inherent stretch. It's crucial that the fabric can withstand the heat press tension. We always recommend pre-shrinking and heat-setting the fabric before printing.

- Moisture Management: Many performance polyesters have a moisture-wicking finish. This must be applied before sublimation.

In 2023, a UK yoga wear brand had issues with printed panels shrinking after printing. The root cause was using an un-stabilized knit. Switching to a pre-stabilized, heat-set interlock solved the problem.

Why is Fabric "Preparation" or "Pretreatment" So Critical?

"Prepared for dyeing" (PFD) fabric has undergone specific washing and bleaching to remove all oils and residues. If these contaminants are present, they will cause uneven spots or reduced color yield. A high-quality supplier like Shanghai Fumao will always offer PFD fabrics for sublimation as a standard.

What Are the Common Pitfalls and How to Avoid Them?

Even with the right fabric, small oversights can ruin a print run.

How Does Fabric Moisture Content Affect the Print?

This is a silent killer. Polyester fabric must be completely dry before printing. Any moisture turns to steam during the heat press, which can result in splotchy, uneven color. Before a big job, printers should "pre-press" the fabric to drive off moisture. Our QC protocol now includes a moisture meter check.

Can You Dye Sublimate on Dark-Colored Fabrics?

The short answer is no, not directly. Dye sublimation is a dyeing process. You cannot dye a dark fiber a lighter color. The ink is translucent. Therefore, sublimation requires a white or very light-colored base to show the true color of the dye.

What About Wrinkle Resistance and Silicone Contamination?

Some fabrics are treated with wrinkle-resistant or softener finishes that contain silicone. Silicone is the enemy of sublimation—it creates a repellent barrier on the fiber. Always explicitly ask your supplier: "Is this fabric free from silicone-based softeners? It is intended for dye sublimation." The community-driven Sublimation Forums on platforms like Reddit are full of real-world troubleshooting stories that highlight issues like this.

Conclusion

Choosing the best fabric for dye sublimation printing is a strategic decision that balances chemistry, construction, and end-use. By insisting on a high-quality, prepared, bright-white polyester fabric with the right weight and construction, you lay the foundation for stunning, durable, and successful printed goods.

Mastering this knowledge empowers you to communicate effectively with suppliers, avoid costly mistakes, and consistently deliver products that wow your customers.

Ready to bring your most vibrant designs to life on the perfect fabric? At Shanghai Fumao, we specialize in supplying a wide range of optimized, PFD polyester fabrics specifically engineered for the dye sublimation market. Let us be your partner in print. For expert guidance and samples, contact our Business Director, Elaine, at elaine@fumaoclothing.com.