Imagine selling a premium rain jacket that keeps the rain out perfectly—only to have your customer return it because they're soaked in sweat after a 15-minute walk. This is the classic, painful paradox of waterproof gear: trapping moisture inside. For decades, the holy grail has been a fabric that is both utterly waterproof and supremely breathable. The solution has been membranes like Gore-Tex, but the game is changing fast. We're now seeing a wave of innovations that are lighter, more sustainable, and smarter than ever before.

So, what's really new? The latest innovations aren't just about making a better plastic sheet. They're about reimagining the membrane itself—its structure, its source materials, and its integration with the fabric. We're talking about biodegradable plant-based membranes, electrospun nanofibers that create airy yet impenetrable webs, and smart membranes that physically change structure in response to body heat and humidity. For brands and product developers, this means moving beyond generic "waterproof" claims to offering targeted performance for specific activities.

As a fabric developer in Keqiao, working with global outdoor brands, I've seen these technologies move from lab samples to production lines. The shift is from one-size-fits-all to engineered solutions. Let's dive into what's next and how it can transform your products.

Are Traditional Laminates Like Gore-Tex Becoming Obsolete?

Let's be clear: traditional expanded polytetrafluoroethylene (ePTFE) membranes like Gore-Tex and its polyurethane (PU) laminate cousins are not obsolete. They are proven, reliable workhorses. Their core principle—a microporous film with holes smaller than a water droplet but larger than a water vapor molecule—remains valid. However, their dominance is being challenged on three key fronts: environmental impact, weight, and adaptive performance.

The main criticism of traditional membranes is their reliance on per- and polyfluoroalkyl substances (PFAS), the "forever chemicals" used in durable water repellent (DWR) finishes and sometimes in membrane manufacturing itself. Regulatory pressure in the EU and US is mounting, and consumer awareness is skyrocketing. Brands are actively seeking PFAS-free waterproof alternatives. This isn't just a trend; it's a fundamental pivot.

Secondly, weight savings are critical for the fast-growing fastpacking and ultra-light hiking markets. Traditional 3-layer laminates, while durable, add measurable grams. The innovation is in creating equally protective barriers that are featherlight.

Finally, traditional membranes have a fixed level of breathability. The new frontier is membranes that adapt—breathing more when you need it (high exertion) and sealing up when you don't (static in a downpour).

What Are the Main Types of Modern Membranes?

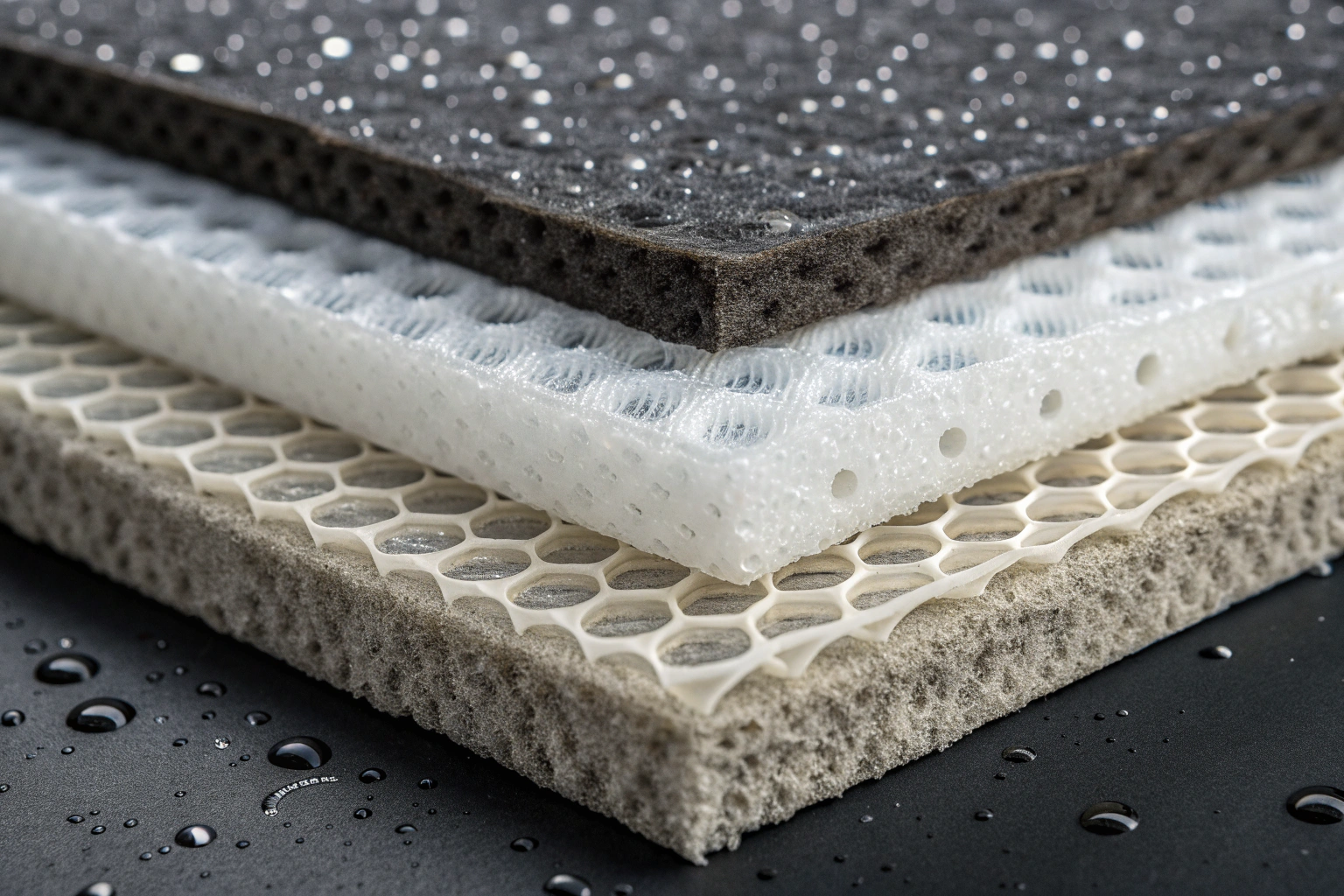

To understand the innovations, you need to know the playing field:

- Microporous Membranes (e.g., Gore-Tex, generic ePTFE/PU): Work on the size-exclusion principle. Think of a microscopic mesh.

- Hydrophilic Membranes (e.g., Sympatex, some PU films): Have no physical pores. Instead, they use a chemical gradient to "pump" water vapor molecules from the inside (high humidity) to the outside (low humidity).

- Bi-component/Mixed-Matrix Membranes: The latest hybrid approach, combining porous and non-porous technologies for enhanced performance.

How Is Sustainability Driving Membrane Chemistry?

The biggest single driver is the move away from PFAS. Innovators are exploring:

- PFAS-Free DWRs: Based on long-chain hydrocarbons or dendrimer technology. While effective, their durability has historically been less than C8 DWR. The latest iterations, however, are closing the gap rapidly. A major North American outdoor brand we partnered with in late 2023 successfully transitioned their entire rainwear line to a new hydrocarbon-based DWR, maintaining a 80/80 water repellency score after 20 home washes.

- Bio-based Membranes: Using polymers derived from castor oil, corn, or other plants to create the polyurethane film itself. While not always 100% bio-based, they significantly reduce fossil fuel dependency. Polyester-based membranes (PBT) are also gaining ground as a more readily recyclable alternative to PU.

What Are the Groundbreaking Technologies in Development?

This is where it gets exciting. The lab coats are earning their keep.

1. Electrospun Nanofiber Membranes:

This is arguably the most significant technical leap. Instead of stretching a solid film to create pores (like ePTFE), this process uses an electric charge to draw ultrafine polymer threads (often 100-500 nanometers in diameter) onto a substrate, creating a non-woven, highly porous mat.

- Why it's innovative: The resulting membrane is extremely breathable due to high porosity, yet waterproof because the nanofibers create a tortuous path that liquid water cannot penetrate. It's also remarkably lightweight and can be made without PFAS chemistry.

- Real-World Status: Companies like Polartec® with their NeoShell® (though not strictly electrospun) pioneered this air-permeable approach. Newer startups are pushing it further. For sourcing, looking into specialized manufacturers of technical nonwovens is key.

2. Smart/Adaptive Membranes:

Imagine a membrane that acts like living skin. Several approaches are in play:

- Temperature-Responsive: Using shape-memory polymers (SMPs) or similar materials where the pore size changes with heat. As your body heats up, the pores expand to vent more vapor. When it's cold, they contract to seal in warmth.

- Moisture-Responsive: Using hydrophilic polymers that swell with humidity. At low humidity (low exertion), the polymer chains are tight, reducing breathability. At high humidity (sweating), they swell and create channels for vapor to escape more rapidly.

This technology is still in advanced development but promises a future where a single jacket is optimal for both a freezing, windy summit and a humid, sweaty ascent.

3. Biomimetic and Asymmetric Membranes:

Copying nature is always a good bet. Researchers are designing membranes that mimic the structure of leaf stomata or fish gills—structures optimized for gas exchange while repelling liquids. Asymmetric membranes have a tight, dense structure on the outer side (for waterproofness) and a more open, porous structure on the inner side (to facilitate vapor transport outward). This directional property enhances overall efficiency.

How Do These Innovations Affect Garment Design and Manufacturing?

New membranes demand new construction techniques.

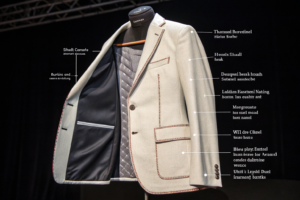

- Ultralight Membranes: Enable the use of incredibly light face fabrics (e.g., 7D-15D nylon), pushing the entire garment weight below 150 grams. This requires precision in lamination and seam sealing to avoid damaging delicate materials.

- Air-Permeable Membranes (like some electrospun types): Can reduce the need for large pit zips, leading to cleaner, simpler designs. However, they may require different lamination adhesives and more meticulous quality control to ensure uniform coverage.

- Recyclability Focus: Innovations like thermoplastic polyurethane (TPU) membranes are a big deal because TPU can be melted and re-extruded. Brands are now designing for end-of-life, creating garments where the face fabric, membrane, and backer are all made from the same polymer family (e.g., all polyester), enabling true mono-material recycling for performance wear. This is a fundamental shift in design philosophy.

How to Evaluate and Source These New Membrane Technologies?

For a brand or developer, navigating this landscape is complex. Here’s a practical framework:

1. Define Your Performance & Sustainability Matrix:

Create a scorecard for what matters most. Is it:

- Absolute Waterproofness (e.g., for extreme conditions)? Look for high hydrostatic head (e.g., >20,000mm).

- Maximum Breathability (e.g., for high-output activities)? Focus on Moisture Vapor Transmission Rate (MVTR) or RET values (<6 is excellent).

- Ultralight Weight? Demand grams per square meter (gsm) specs for the entire laminate.

- PFAS-Free & Recyclability? Require full chemical disclosure and mono-material construction.

You cannot maximize all four at once. Trade-offs exist.

2. Demand Transparent, Third-Party Test Data:

Beware of proprietary "branded" tests with no benchmark. Insist on:

- ISO 811 / AATCC 127: For Hydrostatic Head (waterproofness).

- ISO 11092 / ASTM E96: For Breathability (Ret or MVTR).

- AATCC 22 / ISO 4920: For initial DWR performance.

- Wash/Dry Clean Durability Tests: To see how performance degrades over time (e.g., after 5, 10, 20 cycles).

A reliable supplier will provide this data readily. At Shanghai Fumao, for our technical fabric lines, we provide a digital QR code linking directly to the full test dossier for each membrane batch.

3. Pilot, Prototype, and Torture-Test:

Never commit to a bulk order based on a swatch. Make full prototypes and subject them to real-world conditions that match your end-use. For a trail running jacket, that means having someone run in it for hours in cool, wet conditions. For a ski shell, test it in freezing rain.

Key Sourcing Question to Ask: "Can you provide a compliance certificate for REACH PFAS restrictions and a lifecycle assessment (LCA) summary for this membrane?" This separates the marketers from the innovators.

What Are the Cost Implications and Market Readiness?

- Electrospun & Smart Membranes: Currently at a significant premium (could be 2-3x the cost of standard PU laminate). They are targeting the high-end performance and innovation-focused segments.

- PFAS-Free Bio-based PU Membranes: At a moderate premium (10-30% more), but this gap is closing fast as scale increases. This is becoming the new baseline for responsible brands.

- Traditional PU/ePTFE with PFAS-Free DWR: Now largely cost-neutral as chemical companies have scaled production.

The market is in transition. For Spring/Summer 2026 lines, having a PFAS-free story is becoming mandatory in Europe. The cutting-edge adaptive membranes are likely 2-3 years from mainstream commercial availability, but they are the future.

What Does the Future Hold for Waterproof Breathable Technology?

The convergence of material science, electronics, and sustainability will define the next decade.

1. Integration with Wearable Tech: Membranes could incorporate graphene for enhanced thermal regulation or be paired with micro-ventilation systems activated by sensors.

2. Self-Healing and Self-Cleaning Membranes: Using micro-encapsulation technology, a membrane could release a water-repellent agent to "refresh" its DWR or seal minor abrasions automatically.

3. The "Holy Grail" of Full-Cycle Sustainability: The end goal is a high-performance membrane that is fully bio-based, fully biodegradable under specific industrial composting conditions, and can be efficiently recycled at the end of its high-performance life. This is the ultimate challenge being tackled by consortia like the European Outdoor Group's Circularity Project.

For product creators, the strategy is clear: future-proof your line by engaging with suppliers who are investing in these next-generation technologies, not just reselling last generation's solutions.

How Can a Brand Start Implementing These Innovations?

- Start with a "Hero" Product: Don't overhaul your entire line. Choose a flagship product where the innovation story and performance premium will be valued.

- Partner, Don't Just Purchase: Work with fabric mills and membrane manufacturers who offer co-development. Your specific needs (e.g., a membrane optimized for ocean sailing vs. mountain biking) can drive custom solutions.

- Educate Your Supply Chain: Ensure your garment factory understands how to handle and construct with these new, sometimes more delicate, laminates.

- Tell the Story Transparently: Consumers are savvy. Use clear language about the technology, its benefits, and its environmental profile. Avoid greenwashing.

Conclusion

The world of waterproof breathable membranes is undergoing its most profound transformation since the invention of Gore-Tex. The drive is no longer just for higher performance numbers, but for smarter, cleaner, and more specialized performance. The innovations in electrospinning, adaptive materials, and bio-based chemistry are moving from R&D labs into the garments that will define the next era of outdoor exploration.

For brands, this is a moment of both challenge and immense opportunity. The brands that will lead are those that understand these technologies not as black-box components, but as integral, engineered elements of their product philosophy. They will move from sourcing membranes to co-developing performance ecosystems.

Staying ahead means building partnerships with suppliers who are at the forefront of this change. If you're looking to integrate the next generation of waterproof breathable technology into your line—whether it's a PFAS-free laminate for everyday rainwear or exploring ultra-breathable nanofiber membranes for competition apparel—you need a fabric partner with deep technical expertise and access to innovation. At Shanghai Fumao, we are actively curating and developing these next-generation membrane laminates with our manufacturing partners. Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss how we can help you navigate this new landscape and build technically superior, responsibly made products.