You’ve just landed a major contract to outfit a new hotel chain, or your corporate client needs 5,000 pieces for their frontline staff. The pressure is on. You can’t afford fabric that pills after a month, fades in industrial laundry, or leaves a medical team sweating through their shift. One wrong fabric choice doesn’t just mean returns; it can damage your client’s brand image, employee morale, and your own reputation as a reliable supplier. Sourcing uniform fabric is a high-stakes game where durability, function, and cost must perfectly align.

The core challenge? Each uniform sector—Corporate, Hospitality, Medical—has a completely different set of “enemies.” For corporate, it’s wrinkles and static. For hospitality, it’s red wine and daily washing. For medical, it’s blood-borne pathogens and harsh disinfectants. The fabric you choose is the first line of defense. As a supplier in Keqiao for over 20 years, I’ve seen that the most successful sourcers don’t just buy fabric; they engineer a performance system tailored to each vertical.

This guide will cut through the complexity. We’ll break down the non-negotiable fabric specifications for each uniform type, reveal the most common and costly sourcing mistakes, and provide a step-by-step framework for building a reliable, high-performance supply chain. Whether you’re a procurement manager, a brand owner, or a startup uniform company, this is your playbook for getting it right the first time.

What Makes Corporate Uniform Fabrics Different?

Walk into any bank or corporate headquarters. The uniforms project authority, cohesion, and a polished brand image. The primary “enemy” here is not stains, but wear and tear from office life: chair friction, daily commuting, and the dreaded “afternoon wrinkle.” The fabric must look impeccable from 9 to 5, every single day.

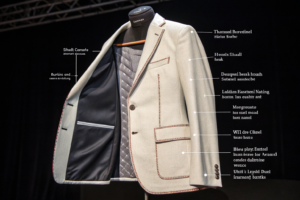

The gold standard here is the polyester-wool blend. Think 55% Polyester / 45% Wool. Why this blend? The polyester provides incredible wrinkle resistance, durability, and shape retention. It lowers the cost and makes the fabric more accessible for large-scale programs. The wool (even at 45%) brings natural breathability, a premium drape, and a sophisticated matte finish that pure polyester can’t replicate. It’s the workhorse of corporate suiting. For warmer climates or budget-conscious programs, a polyester-viscose blend (e.g., 65% Polyester / 35% Viscose) is a fantastic alternative, offering a soft hand feel and excellent color retention.

What Are the Key Specs Beyond Fiber Content?

Fiber content is just the start. To truly differentiate, you must specify the construction.

- Fabric Weight: For year-round corporate wear, look for medium-weight fabrics (240-280 gsm). This provides enough structure for a sharp silhouette without being too heavy.

- Weave: A twill weave is dominant for trousers and skirts due to its diagonal rib, which hides stains and is more durable than a plain weave. For blazers, a plain or hopsack weave offers breathability.

- Finishes: This is where performance is engineered. A durable wrinkle-free finish is non-negotiable. For a premium touch, specify a softening enzyme wash. Most critically, for garments worn in dry, air-conditioned offices, a permanent anti-static finish is a game-changer. We developed a proprietary anti-static treatment for a European airline’s ground staff uniforms in 2023, which reduced static-related complaints from cabin crew by over 90%.

The Sourcing Pitfall to Avoid: Don’t sacrifice colorfastness to rubbing (crocking). A cheap black polyester suit fabric can transfer dye onto light-colored office chairs. Always request and verify AATCC Crocking test reports.

How Do You Source for Large-Scale Corporate Programs?

Volume is your biggest lever and your biggest risk. You need a supplier with massive, consistent production capacity. Key steps:

- Lab Dip Approval is Sacred: Insist on physical lab dip approvals for every color, matching under multiple light sources (D65 daylight, fluorescent, incandescent). A one-off Pantone match is not enough.

- Focus on Batch-to-Batch Consistency: Your 10,000 meters ordered over six months must look identical. This requires a supplier with tight control over their dye house. Partnering with a vertically integrated manufacturer like Shanghai Fumao is key, as we control weaving and dyeing under one roof.

- Audit for Social Compliance: Corporate clients increasingly require evidence of ethical manufacturing. Be prepared to provide audit reports aligned with standards like SMETA or BSCI. Resources like the amfori BSCI platform offer guidance on these requirements.

What Are the Non-Negotiables for Hospitality Fabrics?

Hospitality uniforms live in a war zone. Spills, grease, constant washing (often at high temperatures with harsh industrial detergents), and high-heat environments like kitchens are the norm. The fabric must be a durable, easy-to-clean shield.

For front-of-house (FOH) staff like waiters and hosts, aesthetics are still crucial. A polyester-viscose blend or a high-quality 100% polyester with a natural fiber aesthetic is common. The real hero for FOH is the finish. A high-performance durable soil-release and stain-resistant finish (often using Teflon™ or similar technology) is essential. This causes liquids to bead up on the surface, allowing time for blotting, rather than being absorbed instantly.

For back-of-house (BOH) staff, especially chefs, the requirements are extreme. The classic fabric is a heavy-duty 100% cotton drill or twill (300-350 gsm). Why cotton? It’s naturally breathable and heat-resistant—critical near stoves. However, modern blends are advancing this. A cotton-polyester blend with a flame-retardant (FR) finish is becoming standard for safety. For aprons, PVC-coated polyester or heavy-duty canvas is used for ultimate liquid and abrasion resistance.

How Do You Ensure Fabric Survives Industrial Laundry?

This is the ultimate test. You must source fabric engineered for this punishment.

- Colorfastness is King: The fabric must pass AATCC 61 (Colorfastness to Laundering) at 60°C with a rating of 4-5 (excellent). Anything less will fade quickly.

- Dimensional Stability (Shrinkage): This is a uniform killer. The maximum allowable shrinkage is typically 3% in both directions after five industrial washes. Insist on test reports. In early 2024, we worked with a luxury hotel group in Dubai to replace a failing uniform fabric. The original fabric was shrinking 8%, causing sleeves to rise. By switching to a pre-shrunk, thermoset polyester fabric, we eliminated shrinkage complaints entirely.

- Pilling Resistance: Use Martindale or Random Tumble Pilling tests. A low pilling grade (e.g., 3-4) means the uniform will look old and worn prematurely.

The Sourcing Pitfall to Avoid: Never use fabrics with unstable reactive dyes for dark colors in hospitality. They can “bleed” in the wash, staining lighter-colored linens and other uniforms in the same laundry load.

Where Do You Find Specialized Hospitality Performance Fabrics?

Look for mills and suppliers who specialize in contract textiles or workwear fabrics. They understand the industrial laundry cycle. Key resources include:

- Industry Associations: The International Association of Clothing Designers and Executives (IACDE) often discusses uniform fabric trends.

- Specialized Trade Shows: Events like ISPO (for functional textiles) or Heimtextil have dedicated workwear sections.

These suppliers will have ready-to-go fabric libraries with all the necessary test documentation. A partner like Shanghai Fumao maintains a dedicated inventory of industrial laundry-tested uniform fabrics, complete with QR codes linking to all compliance data, simplifying your procurement and due diligence.

What Fabric Technologies Are Critical for Medical Uniforms?

Medical uniforms are personal protective equipment (PPE). The priorities shift decisively to hygiene, safety, and functionality. The “enemies” are fluids, pathogens, and chemical disinfectants like bleach.

The traditional fabric is a polyester-cotton blend (e.g., 65/35). It’s affordable and breathable. However, the modern standard is moving towards high-performance 100% polyester or polyester with proprietary moisture-wicking technologies. Why? Polyester dries faster, wicks moisture more effectively (critical for managing sweat during long shifts), and can be engineered to have a tighter molecular structure that makes it more resistant to fluid penetration.

What Are the Essential Functional Finishes?

The fabric base is a canvas; the finishes provide the critical protection.

- Antimicrobial/Anti-Odor Finish: This is arguably the most important. It inhibits the growth of bacteria, fungi, and mildew on the fabric itself, reducing the risk of cross-contamination and odor. Look for finishes that are durable to at least 50-100 industrial washes. Technologies can be based on silver ions, zinc, or plant-based compounds.

- Fluid-Resistant/Repellent Finish: A durable water repellent (DWR) finish causes fluids to bead up and roll off, providing a crucial few seconds of protection against splash exposure. It should be tested against ISO 4920 (Spray Test).

- Anti-Wrinkle & Static Control: For a professional appearance and to prevent lint/dust attraction in sterile environments.

For surgical scrubs, breathable, lightweight, and lint-free fabrics are paramount to maintain sterile field integrity.

How Do You Navigate Compliance and Certification?

This is non-negotiable. Your fabric must comply with relevant standards.

- Flame Resistance (FR): For uniforms used in operating rooms or near lasers, FR certification (e.g., NFPA 701) may be required.

- Chemical Resistance: Ensure the fabric and its colors are resistant to common hospital disinfectants like sodium hypochlorite (bleach).

- Biocompatibility: For direct skin contact, ensure dyes and finishes are non-toxic and non-irritating. Oeko-Tex Standard 100 certification is a strong, globally recognized trust signal for this.

When sourcing, demand a technical data package (TDP) for each fabric, including all relevant test reports. For a U.S. medical scrubs brand we supply, we provide a dossier that includes AATCC 100 (Antimicrobial), AATCC 22 (Water Repellency), and Oeko-Tex certificates, which they use for their own FDA device listing requirements for medical apparel.

What Is a Fail-Proof Sourcing Process for All Uniform Types?

Regardless of the sector, a disciplined, step-by-step process will save you time, money, and reputational damage.

- Define the Technical Specification (Tech Pack): Go beyond “blue poly-cotton.” Create a detailed document listing: Fiber content, weight (gsm), weave/knit, width, key performance tests with minimum pass grades (e.g., “Shrinkage: Max 3% per ISO 5077”), and required finishes.

- Source & Sample with Strategic Partners: Don’t just get swatches. Request full development sample cards with the fabric’s technical data. Work with suppliers who ask you detailed questions about the end-use; this shows expertise.

- Prototype & Torture-Test: Make actual garment prototypes. Subject them to real-world conditions: spill red wine on the hospitality fabric, wash the medical scrubs 25 times with bleach, sit in the corporate trousers for a week. Document the results.

- Conduct Pre-Production Validation: Before cutting the bulk order, insist on bulk fabric approval (BFA). The supplier should send you 3-5 meter cuts from the beginning, middle, and end of the first production lot for your final testing and approval.

- Implement Quality Assurance During Production: Use a third-party inspection service or your own QC team to perform During Production Checks (DUPRO) and Final Random Inspection (FRI) at the factory. Check fabric roll-to-roll consistency.

How Can You Mitigate Supply Chain and Cost Risks?

Uniform sourcing is about predictable, long-term supply.

- Diversify Fiber Sources: Don’t rely on a single type of cotton or polyester. Understand global trends in polyester staple fiber pricing to anticipate cost fluctuations.

- Consolidate Sourcing: Using one integrated supplier for multiple fabric types (corporate, hospitality, medical) can streamline logistics, improve bargaining power, and ensure consistent quality standards. This is the core advantage of partnering with a full-service provider like Shanghai Fumao.

- Plan for Lead Times: Remember the production cycles. For a large uniform order needed for a hotel opening in Q4, you should be finalizing fabric and placing the order by late Q1 or early Q2 to avoid peak season delays and the Chinese New Year shutdown.

Conclusion

Sourcing fabric for uniforms is a strategic discipline, not a transactional purchase. It requires moving from a generic “fabric” request to a precise “performance specification” tailored to combat the specific challenges of corporate, hospitality, and medical environments. The common thread is an unwavering focus on durability, tested performance, and compliance.

The most successful uniform programs are built on partnerships with fabric suppliers who act as technical consultants, not just order-takers. They help you navigate the complexities of fiber science, finishing technologies, and industrial compliance, transforming a specification sheet into a reliable, high-performing product that protects both the wearer and your client’s brand equity.

Ready to build a uniform program that stands up to real-world demands? It starts with the right fabric partnership. At Shanghai Fumao, we specialize in developing and supplying technical fabrics for all three uniform sectors. From wrinkle-free corporate suiting and stain-resistant hospitality twills to antimicrobial medical scrubs fabrics, we provide the full package: R&D, testing, certification support, and scalable production. Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss your next uniform project. Let’s engineer the fabric that forms the foundation of your success.