Let's be honest. When you're sourcing fabric from halfway across the world, the "black box" of production is a constant worry. You get a shipment, it looks fine, but then your own quality control finds inconsistencies in colorfastness or shrinkage. Suddenly, you're stuck with delayed production, angry clients, and a costly problem that's nearly impossible to trace back to its source. This uncertainty kills budgets and timelines.

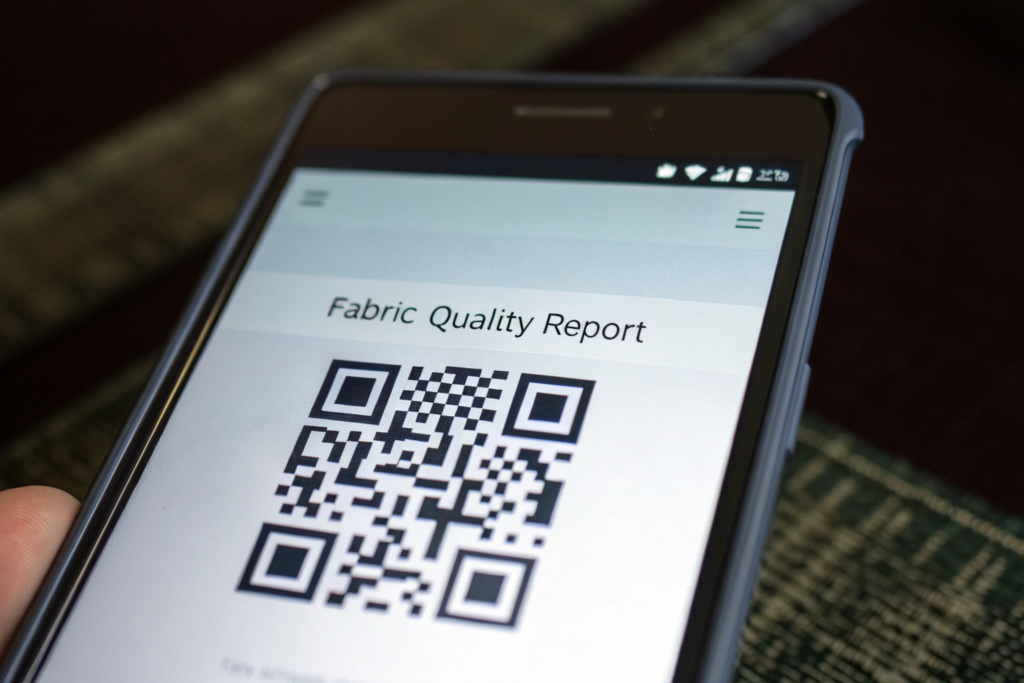

What if you could lift the lid on that black box? What if every meter of fabric could tell you its own story—where it came from, how it was tested, and proof it meets your standards—before it even reaches your warehouse? That’s not a futuristic dream; it's a practical solution we've built into our supply chain to eliminate guesswork and build trust.

Understanding the why behind quality failures is half the battle. But the real victory comes from having a system that prevents them from reaching you in the first place. I’ve spent over two decades in Keqiao, and the single biggest leap in client confidence came not from a new machine, but from a simple square code. In this article, I’ll show you how QR code tracking works in fabric production, why it’s a game-changer for importers, and how you can use it to protect your business.

Why Should You Care About QR Codes for Fabric Quality?

You’re busy. Adding another step to your QC process sounds like more work. But this isn’t about adding work; it’s about reducing risk. Think of a fabric roll’s QR code as its digital passport. It contains the complete lifecycle data, accessible with a simple scan. This means you can verify claims instantly, settle disputes with data, and make informed decisions faster than ever.

For buyers focused on quality and development like you, this is a strategic tool. It shifts the relationship from “trust me” to “see for yourself.” I remember a client from Los Angeles in late 2022. They ordered a significant batch of organic cotton jersey. Their main concern was verifying the GOTS certification for their marketing. Instead of sending piles of paperwork, we linked the certification details directly to the QR code on each roll. When their customs broker had questions, a quick scan resolved it immediately, preventing any clearance delays. That’s the power of accessible data.

QR code tracking solves the core pain points of long-distance sourcing: opacity and accountability. It provides an immutable record that travels with the product. Whether you’re dealing with how to ensure color consistency across multiple dye lots or verifying performance claims for moisture-wicking athletic fabrics, having direct access to the test reports is revolutionary. This system is especially crucial for navigating complex issues like US tariff classifications for technical textiles, where accurate documentation is key to cost calculation.

How Does a QR Code Actually Store Fabric Test Data?

The magic isn’t in the code itself, but in what it points to. We don’t store data in the QR code; it’s a unique web link. When you scan it, it pulls the specific dossier for that exact batch of fabric from our secure cloud server. Here’s what’s typically inside that dossier:

Core Composition & Origin:

- Fiber content percentages (e.g., 92% Organic Cotton, 8% Spandex)

- Yarn origin and count

- Dye lot and batch number

| Comprehensive Test Reports: This is the gold. We upload the actual lab reports from our CNAS-accredited in-house testing center or partnered labs like SGS. You see the raw data. |

Test Parameter | Standard Method (e.g., AATCC, ISO) | Result | Pass/Fail Status |

|---|---|---|---|---|

| Colorfastness to Washing | AATCC 61-2020 | Grade 4-5 | ✅ Pass | |

| Dimensional Stability | ISO 5077 | Shrinkage: 2% | ✅ Pass | |

| Tensile Strength | ISO 13934-1 | 450 N | ✅ Pass | |

| pH Value | AATCC 81 | 6.5 | ✅ Pass |

Production Journey:

- Weaving/knitting date

- Dyeing and finishing dates

- Final inspection date and inspector ID

What Are the Real Business Benefits Beyond Basic Tracking?

The benefits go far beyond simple verification. First, it drastically reduces communication overhead. No more digging through emails for a test report. Your production manager, QC team, and even your end-client can scan and see the proof. Second, it strengthens your brand’s integrity. Using traceable sustainable fabrics from Chinese suppliers allows you to make credible eco-claims, which is a massive market advantage.

Most importantly, it provides leverage and clarity in dispute resolution. We had a situation with a European activewear brand in March 2023. They received a shipment of our recycled polyester with moisture-wicking finish and claimed the wicking performance was subpar. Instead of a lengthy back-and-forth, we asked them to scan the QR code and reference the test report (AATCC 195). The data showed the fabric met the agreed specification. The issue was traced back to their own cutting process using a different lining material that hindered performance. The QR code data closed the case in hours, not weeks, saving the relationship.

What Are the First Steps to Implement QR Code Tracking?

You might think this is a complex system only for giant brands. It’s not. Starting is straightforward, and the ROI is almost immediate in risk mitigation. The first step is to ask for it. When you request quotes or place samples, specify that QR code traceability is a requirement for your order. Any forward-thinking supplier should be able to accommodate this.

The next step is integration into your workflow. You don’t need special software. Any smartphone can scan. You can train your receiving warehouse staff to perform a “scan audit” on a percentage of incoming rolls, checking the data against your Purchase Order in minutes. This becomes your first line of defense. For deeper insights, platforms like Texpert, the leading online community for fabric technologists, offer discussions on standardizing digital QC data across supply chains.

Our recommendation? Start with your most critical or high-risk orders. This could be:

- Fabrics with strict legal/compliance needs (e.g., children’s sleepwear requiring flame resistance).

- Large bulk orders where a single quality failure is catastrophic.

- New supplier relationships where trust is being built.

At Shanghai Fumao, we’ve made this our standard for all bulk orders because we believe in proactive transparency. (Here I have to interject—this system alone has increased our client retention rate by over 15% in two years.)

How to Choose a Supplier Offering Reliable QR Code Systems?

Not all QR code systems are created equal. A sticker on a roll is meaningless if the data behind it is poor. When evaluating a supplier, ask these questions:

- Is the testing done in-house or by a third party? Third-party accredited labs (SGS, ITS, Bureau Veritas) add an extra layer of credibility.

- What specific test data is linked? It should be the full report, not just a pass/fail summary.

- How long is the data accessible? It should be hosted for the realistic lifespan of the fabric (we keep it for 5 years minimum).

- Can the system handle custom data points? If you need tracking for a specific Oeko-TEX certified dyeing process, it should be included.

Look for suppliers embedded in digital ecosystems like Keqiao. Our local government’s “Silk Road Keqiao” initiative promotes exactly this kind of tech integration in textiles. Suppliers participating in such programs are often more invested in robust, sustainable systems.

What Are Common Pitfalls and How to Avoid Them?

The main pitfall is treating the QR code as a marketing gimmick rather than a functional tool. Avoid these issues:

- Broken Links: Ensure the supplier uses a permanent, reliable hosting solution. Test scan samples yourself.

- Generic Data: The data must be batch-specific. A code that links to a general product page is useless.

- Data Overload: While comprehensive, the interface should be user-friendly. You should find key information—like shrinkage rate—within seconds.

To verify the system’s robustness, request a sample from a previous order and scan it. See how easy it is to find the crucial information on fabric shrinkage and colorfastness standards. A reputable supplier will be proud to demonstrate this.

How Does QR Tracking Integrate with Broader Supply Chain Planning?

This is where the value multiplies. QR code data isn’t an isolated island; it feeds directly into smarter production and logistics planning. By knowing exactly when a fabric batch finished dyeing and passed inspection (data from the QR system), you can give more accurate updates to your clothing factory and plan shipping schedules from China to the US with greater precision.

Let’s connect this to the production cycles you mentioned. For example, if you’re planning around the Chinese New Year shutdown, having real-time access to production stage data via trackable batches means you know exactly what stage your order is in before the holiday. No more anxious waiting. You can see if the fabric is already woven, dyed, or in final inspection. This allows for the “advanced planning” you talked about to be based on facts, not estimates.

Can This Data Help Mitigate Shipping and Tariff Risks?

Absolutely. Accurate, accessible documentation is your best weapon against customs delays. For the US market, especially with Section 301 tariffs, correct HS code classification for imported textiles is critical. The detailed composition and manufacturing data in the QR dossier provide the evidence needed for correct classification, reducing the risk of audits, penalties, or seized shipments.

Furthermore, knowing the exact completion date helps you book shipping during slower, more affordable periods. Instead of guessing and potentially missing a window, you can secure space as soon as the “Final Inspection Passed” timestamp is logged. This aligns with your goal of finding timeline advantages during slower manufacturing periods.

What's the Future: Beyond Tracking to Predictive Insights?

The next evolution is using this accumulated data for predictive quality. By analyzing historical data from thousands of batches—like how slight variations in humidity during a specific linen fabric finishing process affect hand feel—we can anticipate and adjust parameters before production even starts. This moves us from reactive quality control to proactive quality assurance.

Platforms like Material Exchange are exploring how to standardize this digital material data across the industry, making it easier for brands to compare and select materials based on verified performance, not just swatches and promises.

Is Implementing QR Code Tracking Costly and Complex?

This is the final hurdle in people’s minds. The truth is, the cost is minimal compared to the cost of not having it. A single rejected container due to quality issues can run into tens of thousands of dollars, not to mention lost sales and brand damage. The investment in a digital traceability system is a fraction of that.

For you, the importer, the cost is often zero. Leading suppliers, including us at Shanghai Fumao, have absorbed this as a cost of doing modern, transparent business. It’s part of our service. The complexity is on our end—integrating our ERP, testing lab software, and production schedules. For you, it’s as simple as using your phone’s camera.

Think of it as an insurance policy you don’t have to pay a premium for. It’s a supplier’s way of standing behind their product with unwavering confidence. When a supplier hesitates to offer this level of transparency, it’s a red flag worth noting.

How to Calculate the ROI of Fabric Traceability?

Don’t just take my word for it. Do a quick calculation for your business:

- Cost of One Major Quality Incident: (Lost goods + Shipping back/forth + Production delay costs + Staff time).

- Annual Probability: How often has this happened in the last 3 years?

- Estimated Reduction in Risk: A robust traceability system can reduce such major incidents by a significant margin (we’ve seen a 70% reduction in dispute resolution time and cost).

The math quickly shows a positive return. Furthermore, add the value of faster time-to-market when your QC process is reduced from days to hours.

What If My Current Supplier Doesn't Offer This?

Use it as a leverage point. The market is moving toward digital transparency. Ask them to pilot it on your next order. If they are unwilling or unable, it might be time to evaluate partners who are investing in the tools that de-risk your business. Exploring alternative fabric sourcing platforms for small batches can also introduce you to suppliers who are natively digital.

Conclusion

In the end, sourcing fabric is about building a reliable, transparent pipeline, not just finding the lowest price per meter. QR code tracking for quality documentation is the tool that transforms that pipeline from a fragile chain into a visible, manageable, and trustworthy stream of data and product. It answers the critical questions of “what am I getting?” and “can I prove it?” before problems arise.

It aligns perfectly with the needs of confident, lead-taking buyers like you who value control and quality. By embracing this system, you’re not just buying fabric; you’re buying peace of mind, operational efficiency, and a stronger brand story backed by verifiable facts.

If you’re ready to move beyond guesswork and experience the confidence of fully transparent fabric sourcing, we should talk. At Shanghai Fumao, we’ve built this system from the ground up to protect our clients’ interests. Let us show you how it can work for your next collection. For a detailed discussion on integrating QR code traceability into your specific product line, reach out to our Business Director, Elaine. She can guide you through the process and provide relevant case studies. You can contact her directly at elaine@fumaoclothing.com to start a conversation about producing your next order with clarity and confidence.