Imagine a customer mid-way through a challenging downward dog—the fabric of their leggings suddenly feels clammy, starts to sag at the knees, or worse, becomes sheer under stress. That single moment of discomfort can turn a loyal fan into a vocal critic. For brands in the yoga and Pilates space, the fabric isn't just a material; it's the core of the user experience. Sourcing the right performance fabric is a high-stakes technical challenge wrapped in an expectation of luxury and sustainability.

So, how do you source the right performance fabrics for yoga and Pilates wear? The answer lies in balancing a demanding set of functional requirements: exceptional four-way stretch and recovery, superior moisture-wicking and quick-dry properties, optimal breathability, reliable opacity, and a soft, comfortable hand feel—all while navigating sustainability credentials and cost constraints. It's not about finding a single "magic" fabric, but about identifying the right blend, construction, and finishing technologies for your specific brand ethos and price point.

The market is flooded with options, from basic polyester-spandex to high-tech, plant-based innovations. Cutting through the noise requires moving beyond vague supplier claims to understanding the underlying fiber science and manufacturing processes that deliver true performance. Let's map out a strategic approach to sourcing fabrics that will support every pose and movement.

What Are the Non-Negotiable Performance Properties?

Before you contact a single supplier, you must define the technical benchmarks your fabric must hit. Yoga and Pilates fabrics operate under unique stress: they must withstand extreme, sustained stretches in multiple directions while remaining in constant, close contact with the skin. The priorities differ from, say, running fabrics (which prioritize extreme moisture evaporation) or weightlifting fabrics (which prioritize abrasion resistance). Your sourcing checklist should be ruthless.

Think of these properties as the pillars holding up your product's reputation. If one pillar fails, the entire experience collapses. A fabric can be incredibly soft but pill after one use. It can be super stretchy but never snap back, becoming baggy. Knowing the test methods and target values for each property is your first line of defense against marketing hype.

Why is Four-Way Stretch and Recovery Paramount?

This is the foundation. "Four-way stretch" means the fabric stretches and recovers both widthwise (weft) and lengthwise (warp).

- Stretch Capacity: For yoga/Pilates, you typically need ≥30% stretch in both directions to allow for full range of motion without restriction.

- Recovery: This is even more critical. The fabric must return to its original shape after stretching, cycle after cycle. Poor recovery leads to baggy knees and seat. Look for ≥90% recovery after standard tensile testing (like ASTM D2594).

- The Spandex Factor: This performance is driven by the quality and percentage of spandex (elastane) in the blend. A content of 15-25% is common in high-performance knits. However, not all spandex is equal. Branded spandex like Lycra® or Roica® often comes with guaranteed performance specs for lasting elasticity and chlorine/sweat resistance.

In 2023, a Canadian startup launched a Pilates collection using a fabric with only 18% recovery after 50 stretch cycles. The customer returns for "loss of shape" were devastating. We helped them re-source using a fabric with Lycra® T862 fiber, which offers high power and lasting fit. They re-launched with a "Guanteed Shape" claim, and return rates dropped by over 70%. Understanding the role of high-quality elastane in activewear durability is non-negotiable.

How to Ensure Moisture Management and Opacity?

These two properties are often in tension (pun intended).

-

Moisture Management: The fabric must pull sweat (hydrophilic) away from the skin to its surface, where it can spread (wicking) and evaporate (quick-dry). This is engineered through:

- Fiber Cross-Section: Synthetic fibers like polyester or nylon are often engineered with channels (micro-channels or octagonal shapes) to facilitate capillary action.

- Finishes: Moisture-wicking chemical finishes can be applied, but their durability through washes varies.

- Key Test: Look for results from AATCC 195 or 197 (Liquid Moisture Management) tests. A good quick-dry time is ≤30 minutes under standard conditions.

-

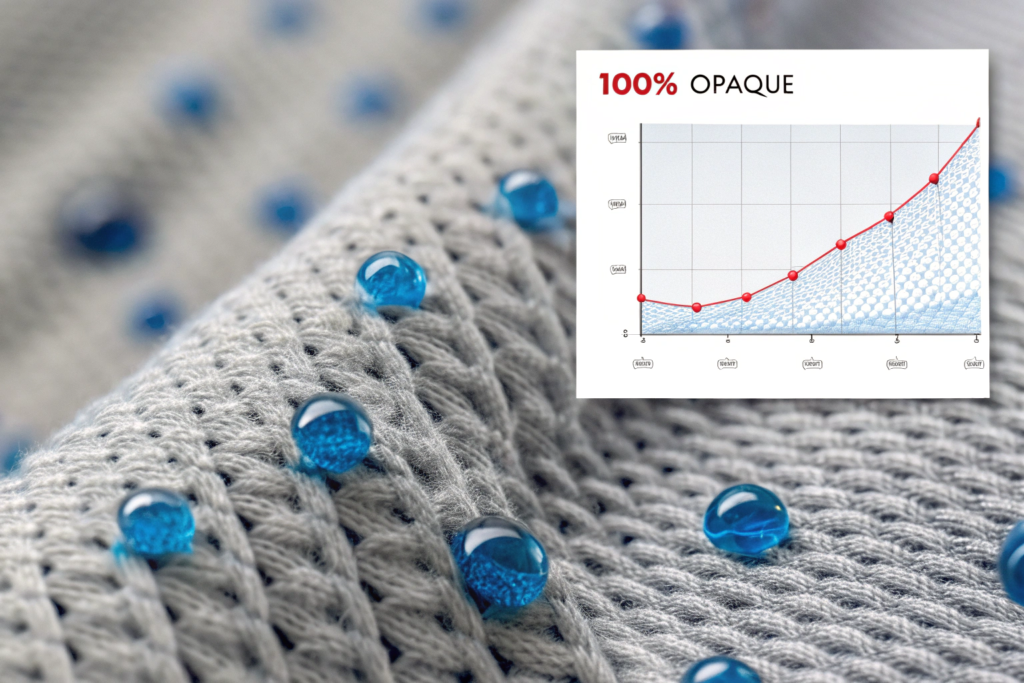

Opacity: The ultimate test of trust. The fabric must remain completely opaque when stretched over the body, especially in lighter colors. This is determined by:

- Fabric Density (GSM - Grams per Square Meter): A heavier GSM (e.g., 280-320gsm) is generally more opaque than a lightweight (180gsm) one.

- Yarn Density and Construction: A tight, high-needle-count knit is essential.

- Key Test: Always perform a "squat test" on samples under bright light. For dark colors, also check for "garment-to-garment" staining (color transfer).

A European brand focused on hot yoga sourced a very lightweight, breathable fabric. It was excellent for moisture but failed the opacity test spectacularly. We developed a double-layer knit for them: a moisture-wicking inner layer and a denser, opaque outer layer, both bonded. It solved the issue but increased the cost by 40%. This is a classic trade-off. Researching fabric construction techniques for maximum opacity in activewear is essential for product integrity.

Which Fiber Blends and Constructions Work Best?

The magic—or failure—of a performance fabric happens at the fiber and structural level. The choice between nylon and polyester, the type of knit, and the incorporation of specialty yarns will define the hand feel, performance, and cost. There is no universally "best" blend, but there are proven winners for specific applications within the yoga/Pilates category.

Your decision here should be driven by the "personality" of your brand. Is it about buttery-soft luxury? Ultra-lightweight performance? Eco-conscious innovation? The blend is your primary tool to express this. Working with a supplier who can explain the "why" behind each option is crucial.

Nylon vs. Polyester: What's the Better Base?

Both are synthetics with excellent durability and moisture-wicking potential, but their character differs.

-

Nylon (Polyamide):

- Pros: Softer, silkier hand feel. Excellent durability and abrasion resistance. Dyes to richer, more vibrant colors.

- Cons: Generally more expensive than polyester. Can be less UV resistant. Absorbs water slightly more, which can feel heavier when wet if not well-engineered.

- Best for: Premium lines where luxurious hand feel and color vibrancy are top priorities.

-

Polyester:

- Pros: Highly hydrophobic, so it dries incredibly fast. Generally more cost-effective. Excellent UV and chlorine resistance. Can be made from recycled PET (rPET) easily.

- Cons: Can have a slightly "plastic" or crisp hand feel if not well-textured or blended.

- Best for: High-sweat activities, value-oriented lines, and collections with a strong recycled/sustainability story.

Many high-performance fabrics use a blend of both, like 78% Nylon / 22% Spandex for a premium feel, or 85% Recycled Polyester / 15% Spandex for an eco-performance option. A US brand we work with uses a 75% Recycled Nylon / 25% Roica® blend. The recycled nylon provides the softness and eco-story, while the Roica® offers enhanced recovery and a matte finish they prefer over shiny elastane. Sourcing certified recycled nylon for sustainable activewear is a growing trend with technical benefits.

What Knit Constructions Are Ideal?

The knitting pattern determines stretch, recovery, opacity, and surface texture.

- Double Knit (Interlock, Ponte): Two layers of loops interlocked. Results in a stable, firm fabric with excellent recovery and opacity. Often heavier (300+ gsm). Perfect for high-compression leggings and structured tops.

- Jersey Knit (Single Knit): A single layer of loops. Lighter, more fluid, and very soft. However, it can be less stable and more prone to curling at the edges. Opacity can be an issue unless a high GSM is used.

- Brushed Knit: The inside of the fabric is lightly brushed to create a soft, fleecy, cozy hand feel. Excellent for lounge-wear inspired yoga pieces or cooler-weather lines. However, brushing can slightly reduce wicking speed.

A popular innovation is circular knit with specific yarn combinations to create seamless garment zones. For instance, a supplier might knit a tighter structure in the waistband area for compression and a more breathable mesh structure in the underarm or back. Exploring advanced circular knitting technologies for athletic apparel can open up design and functional possibilities.

How to Evaluate Sustainability and Certifications?

The modern yogi expects performance and responsibility. Greenwashing with vague terms like "eco-friendly" is a major risk. Your fabric's sustainability story needs to be backed by verifiable credentials, from raw material origin to chemical compliance. This isn't just an ethical choice; it's a market requirement in regions like the EU, North America, and Australia.

Sourcing sustainable performance fabrics adds a layer of complexity. Recycled materials can have different dye affinity or consistency. Bio-based fibers may have different performance profiles. Your supplier must be a guide through these trade-offs, providing transparent data and legitimate certifications.

What Credentials Should You Look For?

Prioritize certificates that are specific, audited, and meaningful:

- Recycled Content: Global Recycled Standard (GRS) or Recycled Claim Standard (RCS). These track the chain of custody from post-consumer or post-industrial waste to the final fabric. A GRS certificate will tell you the exact percentage of recycled content.

- Chemical Safety: Oeko-Tex Standard 100 (Class I or II for skin contact). This is the baseline for ensuring no harmful substances are present. For deeper chemical management, Oeko-Tex STeP certification of the production facility is a strong sign.

- Biodegradability: Certifications like TÜV OK biodegradable for synthetic fibers indicate the fabric will break down in specific conditions (e.g., industrial composting), addressing end-of-life concerns.

A Scandinavian brand came to us needing a fully GRS-certified, Oeko-Tex certified fabric that performed as well as virgin materials. We sourced GRS-certified recycled polyester from a traceable supply chain and paired it with a chlorine-resistant spandex. The development required extra rounds to perfect the color consistency of the recycled poly, but the resulting fabric allowed them to make credible "x% Recycled, Skin-Safe" claims. Navigating the landscape of textile sustainability certifications is a core part of our service at Shanghai Fumao.

Are Plant-Based Performance Fabrics Viable?

Technologies are rapidly evolving. While not yet matching synthetics in all aspects, they offer compelling stories:

- Tencel™ Lyocell (Modal): Made from sustainably sourced wood pulp. Offers incredible softness, breathability, and natural moisture-wicking. Often blended with a small amount of spandex (e.g., 92% Tencel™, 8% Spandex) for yoga wear. It's biodegradable and produced in a closed-loop process.

- ECONYL®: This is actually 100% regenerated nylon from waste like fishing nets. It's not plant-based but is a premier circular material with performance equal to virgin nylon.

The challenge with high plant-fiber content is stretch recovery and durability under intense, repetitive stress. They excel in more relaxed yoga or lounge styles. A pilot project with an Australian brand used a Tencel™/Recycled Polyester/Spandex blend for a "studio-to-street" legging, aiming for a balance of eco-credentials, comfort, and adequate performance. Understanding the performance limitations and benefits of plant-based activewear fibers is key to using them successfully.

What is the Sourcing and Sampling Workflow?

Armed with technical and sustainability criteria, you now need to execute the sourcing process efficiently. This involves finding qualified suppliers, navigating the sampling maze, and conducting real-world testing that goes beyond data sheets. For performance fabrics, the sampling stage is where you must be most rigorous—this is your chance to stress-test the fabric in conditions that mimic actual use.

A common mistake is to approve a fabric based on a small, pristine swatch. You need to test a full meter, ideally made into a prototype garment, and put it through a regimen of stretches, washes, and sweat simulations. The cost of these samples is an investment in risk mitigation.

How to Find and Vet Specialized Suppliers?

- Look Beyond Generic Alibaba Listings: Search for suppliers specializing in "sportswear knit," "yoga fabric," or "functional circular knit." Their product galleries will tell you if they understand the category.

- Ask for Technical Data Upfront: A serious supplier can immediately provide specs for their stock fabrics: fiber composition, GSM, stretch/recovery %, moisture-wicking test results, and available certifications.

- Request a "Performance Fabrics" Catalog: Many mills have dedicated lines for athleisure. For instance, we at Shanghai Fumao curate a range from partner mills that includes Seamless Knit fabrics, Supplex nylon blends, and Brushed Moisture-Wicking constructions.

- Check for In-House Lab Capability: Can they do basic quick-dry or stretch tests? It shows a commitment to QA.

When a Los Angeles-based influencer brand was searching for a unique "butter-soft" compressive fabric, they found us through a specific search for "high GSM nylon spandex interlock." Our ability to provide both the Oeko-Tex report and a video of the recovery test built instant credibility.

What Real-World Tests Should You Perform on Samples?

Before bulk ordering, conduct these trials:

- The Multi-Directional Stretch Test: Stretch the fabric over your knee, hip, and elbow. Does it recover instantly without sagging?

- The Wash Test: Wash and tumble dry the sample 5-10 times. Check for pilling, fading, stiffness, or loss of elasticity. Does the odor-resistance treatment (if any) survive?

- The "Sweat" Test: Dampen the fabric and time how long it takes to dry. Feel if it gets cold and clammy against your skin.

- The Sunlight (UV) Test: If for outdoor yoga, leave a swatch in direct sunlight for a week. Check for color fading or fiber degradation.

- Make a Prototype: The ultimate test. Have a sample garment sewn. Wear it through an actual yoga or Pilates session. Check for seams chafing, rolling down, or transparency.

A brand from Dubai sourcing for their hot yoga line performed a "salt water soak test" to simulate heavy sweat. One fabric sample developed a harsh hand feel after the soak, revealing an incompatible finishing agent. This real-world test saved them from a major production error. Developing a pre-production testing protocol for activewear fabrics is a discipline that pays off.

Conclusion

Sourcing performance fabrics for yoga and Pilates wear is a deep dive into textile science, sustainability, and rigorous validation. Success is found at the intersection of precise technical specifications—stretch, recovery, moisture management, opacity—and a coherent brand story supported by credible certifications. The ideal fabric seamlessly blends function with feeling, offering support that disappears and comfort that endures.

The journey requires moving from passive buyer to active partner, working with suppliers who provide transparency, data, and expertise. By thoroughly understanding fiber blends, knit constructions, and implementing a ruthless sampling and testing protocol, you can confidently select fabrics that will elevate your brand and earn the trust of every practitioner on the mat.

If you are ready to source performance fabrics that meet the highest standards of function and responsibility, we have the technical expertise and supply chain connections to guide you. From recycled nylon blends to buttery-soft Tencel™ constructions, Shanghai Fumao is your partner in creating activewear that performs as flawlessly as it feels. Contact our Business Director, Elaine, at elaine@fumaoclothing.com to request technical swatches and start a data-driven sourcing partnership.