Worried that hidden chemicals in your fabric could derail your brand's reputation and customer trust? You're right to be concerned. Today's consumers, especially in Europe and North America, are not just buying a product; they're buying a promise of safety and responsibility. Finding a factory that claims compliance is easy, but truly ensuring every meter of fabric consistently meets stringent international safety standards like Oeko-Tex Standard 100 is a different challenge altogether. It requires a proactive, knowledge-driven partnership with your supplier.

So, how can you ensure your fabrics meet Oeko-Tex Standard 100? The answer is a three-part strategy: First, deeply understand the standard's scope and your product class. Second, choose a supplier with integrated, verifiable control systems, not just a certificate. Third, implement your own due diligence through independent verification and clear contractual agreements. It’s about moving from passive hope to active control throughout your supply chain, from raw material selection to final production.

Simply obtaining a certificate isn’t enough; it’s a snapshot. Real assurance comes from embedding safety into the manufacturing DNA. For brands sourcing from Asia, this means going beyond the trade show brochure and auditing the actual processes. Let’s break down the actionable steps you can take to guarantee your fabrics are not just labeled safe, but are verifiably safe for human ecological health.

What Exactly Does Oeko-Tex Standard 100 Test For?

Before you can ensure compliance, you must understand what you're complying with. Oeko-Tex Standard 100 is not a single test; it's a comprehensive system of limit values for hundreds of regulated and non-regulated substances, based on the latest scientific research and international regulations. Crucially, it assesses fabric safety from a human-ecological perspective, considering how the product will be used. A baby's onesie (Product Class I) has far stricter limits than a decorative curtain (Product Class IV).

The standard categorizes substances into several critical groups, each with its own testing protocol. Think of it as a thorough medical check-up for your fabric, screening for harmful "ailments" you can't see. A supplier who truly understands these categories can source raw materials intelligently and adjust processes preemptively, rather than just testing finished goods and hoping for the best. This foundational knowledge is your first line of defense.

Which Chemical Groups Are Under the Microscope?

The testing focuses on substances known to be harmful. Key groups include:

- Illegal Substances: Those banned by law (e.g., certain azo dyes, formaldehyde over legal limits).

- Regulated Chemicals: Those subject to legal limits (e.g., nickel, lead, cadmium).

- Non-Regulated But Harmful Chemicals: Scientifically recognized as harmful but not yet legally restricted everywhere (e.g., allergenic disperse dyes, pesticide residues, chlorinated phenols).

- Parameter for Health Protection: Includes pH value, colorfastness, and smell, which indicate skin compatibility and production hygiene.

For example, in 2023, a Scandinavian childrenswear brand approached us after another supplier failed a test for phthalates in recycled polyester fabrics. Their previous supplier had used cheap, non-certified recycled chips containing plasticizers. Because our CNAS lab routinely screens for such substance groups, we were able to source pre-verified, Oeko-Tex compliant recycled polyester granules, ensuring the entire production chain from chip to fabric was clean. This proactive screening for regulated substances in global textile supply chains is non-negotiable for reliable compliance.

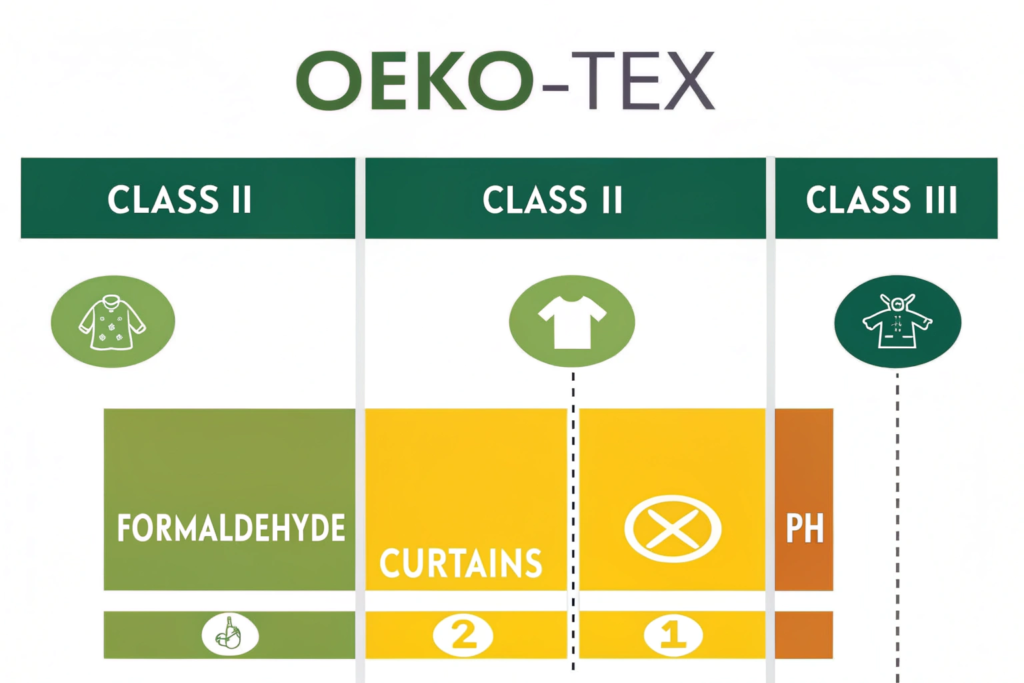

Why is Product Classification (I-IV) Your First Critical Decision?

Your product's intended use directly determines the severity of the limits it must meet. Misclassification is a common and costly error.

- Class I: Articles for Babies & Toddlers (up to 36 months): Most stringent limits (e.g., formaldehyde limit is 20 ppm).

- Class II: Articles with Direct Skin Contact (e.g., blouses, shirts, bed linen): Stricter limits for skin-sensitizing substances.

- Class III: Articles with No or Little Skin Contact (e.g., jackets, coats): Slightly higher permitted limits.

- Class IV: Decoration Materials (e.g., curtains, tablecloths): Highest permitted limits, but still safe for indoor environments.

We worked with a US-based athleisure brand that mistakenly labeled their yoga pants as Class III. When they pursued certification, they failed because leggings are direct skin contact (Class II). The failure was due to a specific allergenic dye. We had to re-engineer the dyeing formula, costing them 5 weeks. Now, we start every project by confirming the product class with our clients. Understanding how to correctly classify products for Oeko-Tex certification is a fundamental step that shapes all subsequent sourcing and production decisions.

How to Vet a Supplier for Real Oeko-Tex Compliance?

A supplier's certificate is a starting point, not a guarantee. The real question is: how is that compliance achieved and maintained day-to-day? Many factories outsource testing and treat it as a final inspection, which leads to risky variability. The suppliers you can trust are those who have integrated safety into their core operations, controlling the process from the very beginning. Your vetting process must go deeper than paperwork.

Look for partners who don't just have a certificate hanging on the wall, but who can explain their control points, show you their in-house testing capabilities, and demonstrate traceability. Ask for evidence, not just assurances. A supplier who is deeply embedded in a professional textile cluster like Keqiao often has better access to pre-certified raw materials and shared testing resources, which is a significant advantage.

What Questions to Ask Beyond the Certificate?

Move the conversation from "if" to "how." Here are critical questions to pose:

- "Can you show me your raw material approval system?" Do they require Oeko-Tex test reports from their yarn or chemical suppliers? At Shanghai Fumao, we maintain a database of approved, pre-tested material sources, which is our first firewall.

- "Do you perform in-house pre-tests before official certification?" A capable supplier will have basic in-house equipment (like pH meters, formaldehyde test kits) and use third-party labs like SGS or our own CNAS lab for regular screenings. This catches issues early.

- "How do you manage production to prevent cross-contamination?" This is vital. Are certified and non-certified productions run on separate lines or with rigorous cleaning protocols? We once audited a mill that failed because they used the same steam valve for certified organic cotton and regular polyester, causing contamination.

- "Can you provide a full test report, not just the certificate?" The certificate is a summary. The full report details every parameter tested and its result. Insist on seeing it.

A German furniture brand vetting us in 2022 spent a day not in our showroom, but in our lab and factory. They wanted to see the quality control protocols for contract textile manufacturing in action—how greige fabric was tested upon arrival, how dye lots were isolated. That hands-on verification built the trust that led to a long-term partnership.

Why is Integrated Production Control the Key?

Compliance cannot be inspected into a product at the end; it must be manufactured into it. An integrated supplier controls, or closely cooperates with, each step: spinning, weaving, dyeing, finishing. This allows for closed-loop management.

- Dyeing & Finishing: This is the highest-risk stage. Compliant dyes and auxiliaries must be used. The chemical supplier's MSDS (Material Safety Data Sheet) and compliance statements are crucial. Our partnered dyeing factory uses an automated dispensing system linked to a database of approved chemicals, eliminating human error in weighing.

- Traceability: From the final fabric roll, you should be able to trace back to the specific dye lot, weaving batch, and yarn origin. Our QR code system provides this digital trail. For instance, when a French brand had a customer inquiry about potential nickel in a metal button thread, we traced the component thread in 2 hours and provided its separate test report, resolving the issue instantly. This level of transparent supply chain management for eco-textiles is what separates true partners from simple vendors.

What Practical Steps Must You Take as a Buyer?

Your responsibility doesn't end with choosing a good supplier. As the buyer and brand owner, you must actively manage the relationship and build in your own safeguards. This involves clear communication, smart contracting, and strategic verification. Think of yourself as the project manager for product safety, with your supplier as your expert execution partner. Your steps turn their capability into your guaranteed outcome.

Being proactive here prevents 90% of compliance headaches. It aligns expectations, defines responsibilities, and creates a shared roadmap. The most successful brands we work with treat Oeko-Tex compliance as a joint project from the initial design stage, not as a last-minute box to check before shipment.

How to Structure Your Contract and Specifications?

Your purchase contract and tech pack are your legal and technical tools for enforcement. Be explicit.

- Incorporate the Standard by Reference: State clearly: "All goods must conform to Oeko-Tex Standard 100, Product Class [specify], current version at time of production."

- Specify Testing and Documentation: Require that testing be performed by an Oeko-Tex approved institute (like Hohenstein, TESTEX) on the finished fabric. Specify that the official Oeko-Tex certificate and full test report are required deliverables before payment is released.

- Define Non-Compliance Consequences: Stipulate that any batch failing to meet the standard will be rejected at the supplier's cost, including all logistics and testing fees. This aligns financial incentives.

- Require Ingredient Disclosure: Ask for a list of all dyes and major auxiliaries used, to ensure no banned substances are introduced.

A practical example: A UK sustainable brand includes a clause that 5% of each shipment, selected at random by their appointed third-party inspector, will be sent for independent verification testing. The cost is shared, but the risk of a failed shipment is nearly eliminated. This practice of conducting third-party inspections for imported fabrics is a powerful deterrent against complacency.

Should You Conduct Independent Verification Testing?

Yes, absolutely. While relying on the supplier's certificate is standard, conducting your own spot-check testing through a reputable third party like SGS, Bureau Veritas, or directly through an Oeko-Tex institute is the ultimate safeguard. This is especially critical for:

- First-time orders with a new supplier.

- High-volume orders where risk is magnified.

- Orders for sensitive product classes (I or II).

The cost is an insurance premium. In Q4 2023, one of our long-term clients from California still randomly selected one roll from a 10,000-meter shipment of organic cotton jersey for independent testing. The results matched our report perfectly, reinforcing trust. They share this verification story with their own customers, enhancing their brand's credibility. For high-stakes orders, understanding the process and cost of third-party textile laboratory testing is a wise investment in risk management.

How Do You Handle Recertification and Ongoing Compliance?

Oeko-Tex certification is not a one-time event; it's valid for one year. Furthermore, the standard itself is updated annually based on new scientific findings. This means compliance is a continuous journey, not a destination. Your supplier must have a system for managing recertification and staying abreast of regulatory changes. For you, this means choosing a partner with a long-term, adaptive approach, not one looking for a quick transaction.

The most common pitfall is assuming that once certified, always certified. Changes in raw material suppliers, dye recipes, or finishing processes can all invalidate a certificate. A proactive supplier manages these changes under a defined management-of-change procedure and re-tests when necessary.

What is the Recertification Process and Timeline?

The official recertification should be initiated by your supplier well before the current certificate expires—we recommend starting 3 months in advance. The process involves:

- Application Review: Submitting updated information on products and processes.

- Product Testing: Submitting new samples for testing against the current version of the standard.

- On-Site Audit (possible): Oeko-Tex may conduct surprise audits to verify ongoing compliance with production practices.

A smooth recertification depends on having clean, organized records of all material changes throughout the year. We manage this for our clients through a digital dashboard where they can see the status of all certifications for their active fabrics. This prevents the nightmare of a lapsed certificate holding up a shipment. Reliable partners offer guidance on navigating annual updates to international textile safety standards.

How to Manage Changes in Production or Materials?

Any change must be treated as a potential risk. Establish a clear protocol with your supplier:

- Notification Agreement: Require the supplier to notify you of any planned change in yarn origin, dye-house, or chemical supplier for a certified fabric.

- Re-testing Protocol: Agree that any such change triggers a new round of testing (at least for the affected parameters) before production continues.

- Version Control: Ensure your tech pack and order documents always reference the specific article number linked to its certified recipe.

For example, when the price of a particular Oeko-Tex compliant blue dye spiked in 2023, our dyeing partner proposed an alternative from another certified supplier. Before switching, we ran a small trial batch and sent it for a partial test focused on heavy metals and allergenic dyes. Only after receiving the clear test report did we approve the change and update the article's documentation for all affected clients, including Shanghai Fumao's dedicated brand partners. This disciplined change management is the hallmark of a serious supplier.

Conclusion

Ensuring your fabrics meet Oeko-Tex Standard 100 is a multifaceted endeavor that blends deep knowledge, strategic partnership, and vigilant oversight. It begins with understanding the rigorous "what" and "why" of the standard's requirements, then extends to meticulously vetting suppliers for integrated process control—not just paper certificates. Your role as a buyer is cemented through precise contracting, independent verification, and managing the ongoing cycle of recertification and production changes.

True compliance is a shared commitment to safety that runs through the entire supply chain. It transforms a cost of doing business into a powerful brand asset, building unshakable trust with your customers. In a market where greenwashing is rampant, demonstrable, verifiable safety compliance is a decisive competitive edge.

If you are looking for a partner who treats fabric safety with the seriousness it deserves, with the in-house expertise and integrated control systems to guarantee Oeko-Tex Standard 100 compliance batch after batch, we are here to help. At Shanghai Fumao, our CNAS-accredited lab and deep supply chain partnerships in Keqiao are built to provide this exact assurance. Let's discuss how we can secure the safety and integrity of your next fabric order. Contact our Business Director, Elaine, at elaine@fumaoclothing.com to start a conversation grounded in trust and proven compliance.