If you've been browsing the fabric libraries of major brands or scrolling through sustainable fashion feeds lately, you've definitely seen hemp popping up everywhere. It’s not just a niche, earthy-crunchy material anymore. Top-tier brands from Patagonia to Levi’s are launching hemp collections. But here's the question: is this just another greenwashing trend, or is there a real, tangible reason for this sudden explosion? As someone who’s been in the textile trenches in Keqiao for over two decades, I’ve watched materials come and go. I can tell you, the hemp revival is different. It’s not just about sustainability; it’s about a perfect storm of performance, policy, and consumer demand finally aligning.

So, what exactly is hemp fabric? At its simplest, it's a textile made from the fibers of the Cannabis sativa plant. But that simple definition sells it short. Unlike its notorious cousin, industrial hemp contains minimal THC. The magic is in the stalk. The long bast fibers are processed, spun into yarn, and woven or knit into a fabric that’s incredibly durable, naturally breathable, and gets softer with every wash. Think of it as nature's performance fabric—long before synthetics tried to imitate it. Brands are embracing it now because it solves multiple modern problems at once: the urgent need for eco-friendly materials, the demand for durable, high-quality goods, and the search for a natural fiber that doesn't compete with food crops like cotton.

Let's cut through the hype. The sudden shift isn't accidental. It's driven by brands hitting a wall with conventional materials and consumers becoming savvier. They're tired of polyester microplastics and the colossal water footprint of cotton. Hemp offers a compelling, time-tested answer. But understanding its true potential—and its complexities—is key to deciding if it's right for your next line. Let’s unravel the story thread by thread.

What Makes Hemp Fabric So Unique Compared to Cotton or Linen?

When you feel a good quality hemp fabric, the first thing you notice is its substantial hand-feel. It has a unique, dry yet soft character—it’s strong without being stiff. This comes down to its fiber structure. Hemp fibers are longer, stronger, and more porous than cotton. This translates into fabrics that are about 3-4 times stronger by weight. They don’t pill or wear out easily. I’ve seen hemp canvas bags outlast polyester ones by years. Its porosity makes it highly breathable and moisture-wicking, pulling sweat away from the skin faster than cotton. For activewear or summer shirting, this is a game-changer.

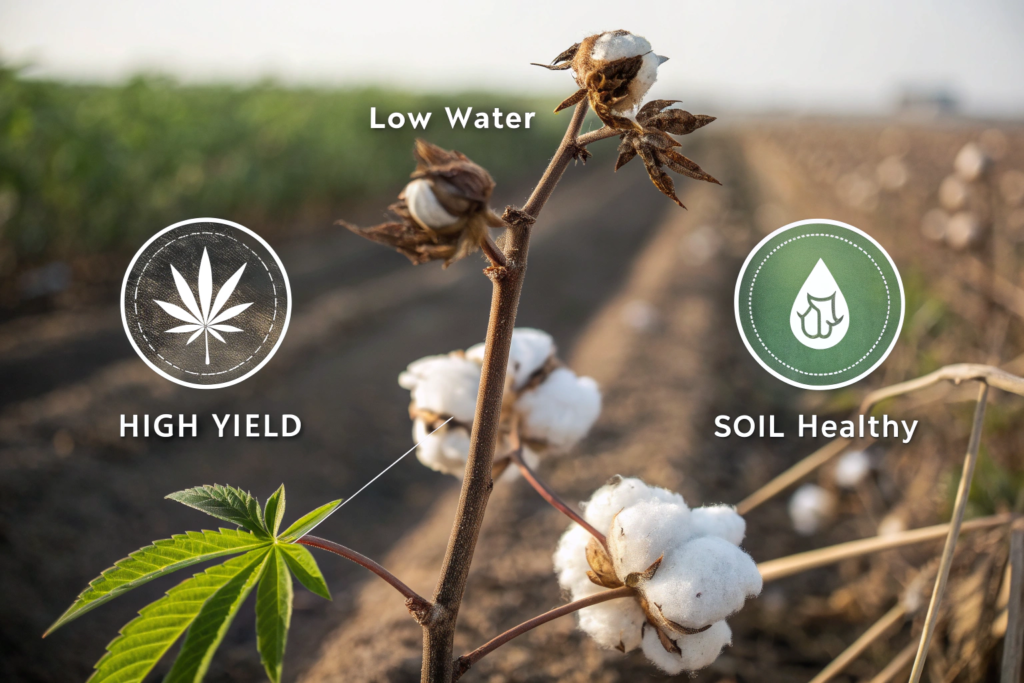

But the real differentiator is its environmental profile. While organic cotton is a step forward, hemp is in another league. It’s a phytoremediator, meaning it cleans the soil it grows in by drawing out toxins. It requires about 50% less water per season than cotton and needs zero to minimal pesticides. It grows densely, yielding more fiber per acre. From a farm-to-fabric perspective, it’s one of the most efficient natural resources we have. For brands under pressure to prove their sustainability claims, these are hard, verifiable facts.

Why is Hemp Considered a “Carbon-Negative” Raw Material?

This term gets thrown around a lot. “Carbon-negative” means the plant absorbs more carbon dioxide from the atmosphere during its growth than is emitted during the entire process of farming, processing, and transporting it. Hemp is a champion at this because it’s a fast-growing biomass crop. One hectare of industrial hemp can absorb up to 15 tonnes of CO2 per hectare. Compare that to forests, which absorb about 2-6 tonnes per hectare per year.

The processing stage is where the choice of partner matters. Traditional chemical retting (separating fibers from the stalk) can be harsh. But modern, controlled enzymatic and mechanical degumming processes have dramatically reduced water and chemical use. At Shanghai Fumao, when we source hemp, we prioritize partners using these cleaner methods and look for credible lifecycle assessment data from organizations like Textile Exchange. This allows us to provide our clients with a fabric that has a genuinely lower climate impact from the very start of the supply chain. For a brand, this isn’t just a marketing point; it’s a tangible contribution to their Scope 3 emissions reduction goals.

How Does the Feel and Performance of Hemp Change Over Time?

This is hemp’s secret weapon. A new, unwashed hemp garment can feel crisp, even a bit rough—this is its honest, rustic character. But with each wash, it undergoes a beautiful transformation. The fibers soften significantly, developing a drape and hand-feel comparable to high-end linen but often with more body. Unlike cotton, which can thin out and lose tensile strength, hemp retains its durability while softening.

We ran a practical test for a Swedish workwear brand in early 2023. They wanted a tough yet comfortable fabric for chef’s aprons. We supplied a 55% hemp / 45% organic cotton twill. They conducted 50 industrial wash cycles. The result? The tensile strength loss was less than 10%, and the fabric’s breathability (measured by moisture vapor transmission rate) actually improved as the fibers opened up. The customer feedback was that the aprons felt “broken in but not worn out.” This aging performance is perfect for brands selling a “buy it for life” or durable goods ethos. It tells a story of longevity that resonates deeply with today’s consumers.

What Are the Real Drivers Behind the Sudden Hemp Boom in Fashion?

The boom isn’t sudden; it’s the culmination of a long push. The primary driver is consumer demand for authentic sustainability. People are educated now. They know “recycled polyester” still sheds microplastics. They’ve seen documentaries on cotton’s water use. Hemp is a new (yet ancient) story they can believe in. It’s a natural, plant-based solution that feels genuinely different from the corporate greenwashing of the past decade.

Secondly, regulatory and agricultural policy shifts have been crucial. The 2018 U.S. Farm Bill legalizing industrial hemp opened the floodgates for American farming and R&D. Similar loosening of regulations is happening in key manufacturing regions. This has stabilized supply chains and brought down the cost of raw hemp fiber. In China, we’ve been working with hemp for years, but now the scale and quality consistency have reached a point where large-scale commercial use is viable. Finally, technological innovation in processing has solved the old “rough” texture problem, allowing for finer, softer yarns suitable for next-to-skin apparel, not just sacks and ropes.

How Has Legalization Changed the Global Hemp Supply Chain?

Legalization, particularly in the U.S., did two critical things. First, it unleashed investment. Farmers could get crop insurance, researchers could secure grants, and manufacturers could build facilities without legal fear. This led to a rapid improvement in seed genetics, yielding plants with higher fiber content and better consistency.

Second, it created a multi-sourced global supply chain. Previously, China dominated. Now, with production in Europe, the U.S., and Canada, brands have options and reduced geopolitical risk. This competition has driven up quality and transparency. For us as a fabric supplier, this means we can now blend fibers from different origins to optimize for cost, quality, and sustainability credentials that matter to specific markets. For example, European brands often prefer EU-grown hemp for its lower transportation footprint, while U.S. brands may want a domestic story. This diversification makes hemp a more reliable and scalable material for global brands.

Is Consumer Demand for Hemp Backed by Willingness to Pay a Premium?

This is the billion-dollar question. The answer is a qualified yes. The market is bifurcating. There’s a segment of deeply committed sustainable consumers who understand hemp’s value proposition and will pay a 20-30% premium over conventional cotton. For them, it’s an investment in a durable, ethical product.

But the real growth is in the middle. Brands are getting clever by using hemp blends. A 30% hemp / 70% cotton blend inherits much of hemp’s strength and moisture-wicking properties, but the price premium drops to maybe 10-15%, making it palatable for a much wider audience. The fabric also feels familiar from day one. Our bestseller in 2023 for the European market was exactly that: a 30/70 hemp-organic cotton jersey for T-shirts. It allowed brands to market a “hemp-infused” product with a compelling story at an accessible price point. The demand isn’t just for 100% pure hemp; it’s for the integration of hemp’s benefits into mainstream apparel.

What Are the Practical Challenges of Sourcing and Working with Hemp Fabric?

Let’s be real: it’s not all easy. Anyone telling you it’s exactly like sourcing cotton is oversimplifying. The challenges are real but manageable with the right partner. The first hurdle is consistency. Hemp fiber can vary more batch-to-batch than cotton, depending on harvest conditions and processing. This can lead to slight shade variations in the natural color and differences in yarn evenness.

The second challenge is dyeing and finishing. Hemp’s high cellulose content and dense fiber structure mean it can be less absorbent than cotton initially. This requires adjustments in dyeing recipes, temperatures, and the use of specialized eco-friendly softeners to achieve consistent, vibrant colors and the desired soft hand-feel. You can’t just throw it into a standard cotton dyeing bath and expect perfect results.

Why Does Hemp Fabric Sometimes Have a Higher Initial Cost?

The cost structure is different. While the farming is efficient, the processing—turning the tough, woody stalk into spinnable fiber—is more energy and labor-intensive than processing cotton bolls or synthetic chips. There are fewer large-scale, automated processing facilities globally, keeping supply somewhat constrained and prices above conventional fibers.

However, this is changing rapidly. As volume increases, economies of scale kick in. Furthermore, the total cost equation must consider durability. A hemp/cotton blend shirt might cost 15% more to produce, but if it lasts twice as long without pilling or losing shape, the cost-per-wear plummets. For brands, this is a powerful narrative: “Premium material for longer-lasting clothing.” It justifies the initial price bump. Sourcing from an integrated supplier like Shanghai Fumao helps control these costs because we optimize the entire process from fiber selection to finishing, avoiding markups at each separate stage.

How Do You Ensure Consistent Quality and Color in Bulk Hemp Orders?

Consistency is where a supplier’s expertise is tested. It starts with strict fiber sourcing specifications. We work with farms and processors who can provide detailed lot information. Then, in our own processing, we implement extra steps.

- Pre-treatment is Key: We use a proprietary, controlled enzymatic pre-wash for our hemp fabrics. This step gently opens up the fiber pores, ensuring uniform dye absorption later on. It’s like prepping a canvas before painting.

- Lab Dip Protocol: We always insist on multiple lab dip approvals for hemp orders. We might send 3-5 dip options with slight variations in dye concentration to account for the fiber’s personality. Clients must approve the physical dip, not just a Pantone number.

- Pilot Batch: For first-time orders or large volumes, we run a pilot dyeing batch of 100-200kg. We test this batch for colorfastness to washing, rubbing, and light in our CNAS lab. Only after it passes all specs do we proceed to full bulk. This extra caution prevents catastrophic, costly mistakes.

A case study: In October 2023, for a California-based lifestyle brand, we produced 10,000 meters of a heather grey hemp fleece. By implementing this rigorous protocol—especially the pilot batch—we achieved a color consistency rate of 98.5% across all rolls, matching their stringent quality requirements. The brand was thrilled because their previous supplier had issues with blotchy dyeing on a similar fabric.

What Does the Future Hold for Hemp in the Textile Industry?

The future is blended and high-tech. Pure 100% hemp fabric will always have its place in niche, artisanal markets. But the massive scale will come from intelligent blends: hemp with organic cotton, hemp with Tencel™, hemp with recycled polyester for performance wear. These hybrids maximize the strengths of each fiber while mitigating their individual weaknesses.

Furthermore, innovation in hemp processing will continue to lower costs and improve softness. We’re already seeing new cottonization techniques that make hemp fibers behave almost identically to cotton in spinning mills. On the chemical side, research into greener retting and finishing agents is making the process cleaner. The future also lies in circularity. Hemp is a natural, biodegradable fiber. At its end of life, in a controlled composting environment, it can return to the soil in months, unlike polyester which lasts for centuries. This closes the loop in a way that truly aligns with a circular economy model.

Will Hemp Become a Mainstream Staple Like Cotton or Polyester?

It won’t replace cotton or polyester entirely—the world’s fiber needs are too vast. But it is poised to become a major third pillar in the natural fiber portfolio. Think of it moving from a “specialty” fiber to a “standard” sustainable option, much like organic cotton did 15 years ago. As supply chains mature, costs will come down further.

The mainstreaming will be driven by large brands making long-term commitments. When a giant like Adidas or H&M signs a multi-year contract for thousands of tons of hemp fiber, it sends a signal to the entire agricultural and manufacturing sector to scale up. This is already beginning to happen. We’re in discussions with several major European brands about such forward contracts for 2025-2026. Their goal is to lock in supply and price to make hemp a cornerstone of their sustainability roadmap.

What New Innovations in Hemp Fabrication Are on the Horizon?

The R&D is exciting. Beyond softer yarns, we’re working on and seeing developments in:

- Hemp-Based Performance Fabrics: Blending hemp with lyocell or modal to create ultra-soft, draping jersey for luxury loungewear. Adding a small percentage of hemp to recycled polyester athletic knit significantly reduces odor retention—a natural anti-microbial property of hemp.

- Waste Utilization: Using the short “hurds” from the hemp stalk (traditionally a waste product) to create hemp-based viscose or lyocell-type fibers. This uses 100% of the plant.

- Natural Finishes: Leveraging hemp’s natural UV resistance and anti-microbial properties to create sun-protective and odor-resistant fabrics without chemical coatings. Our lab is testing a hemp-linen blend for resort wear that achieves a UPF 40+ rating through weave structure alone.

The potential is vast. For forward-thinking brands, getting involved with hemp now isn’t just about a single collection; it’s about building expertise and supply chain relationships for the next decade of sustainable fashion.

Conclusion

Hemp fabric is far more than a fleeting trend. It’s a powerful, practical response to the intertwined crises of environmental impact and consumer demand for authenticity and quality. Its unique combination of legendary durability, exceptional breathability, and a dramatically lower ecological footprint makes it a compelling choice for brands that are serious about their future. The sudden embrace is the result of barriers falling—legal, agricultural, and technological—allowing hemp’s inherent advantages to finally shine on a global scale.

Working with hemp does require a knowledgeable partner. Its quirks in dyeing and sourcing demand expertise, but the rewards—a product story of resilience, sustainability, and timeless quality—are unmatched. As the industry evolves, hemp will move from a statement fabric to a fundamental component of responsible textile sourcing.

If the potential of hemp fabric has sparked your imagination for your next collection, we should talk. At Shanghai Fumao, we’ve moved beyond just offering hemp as a material; we’ve developed deep expertise in blending it, finishing it, and ensuring it performs brilliantly from mill to market. We can guide you through fiber selection, development, and bulk production to create something truly special. To explore how hemp can transform your brand’s offering, reach out to our Business Director, Elaine. Let’s build the future of fabric, together. Contact her at: elaine@fumaoclothing.com.