You're about to wire a large payment for a fabric shipment from overseas. The photos look great, the pre-shipment sample was okay, but a nagging voice in your head asks: "What if the bulk is different?" You've heard horror stories—short yards, mismatched colors, hidden defects that unravel an entire production line. Securing a professional, impartial fabric inspection report before releasing funds is the single most effective way to turn that anxiety into confidence. It's your tangible proof of quality, your insurance policy, and your strongest leverage in ensuring you get exactly what you paid for.

A professional fabric inspection report is not a simple checklist; it's a systematic, standardized audit of the entire shipment's quality against agreed-upon criteria. It quantifies defects, measures compliance, and provides an objective pass/fail verdict. Think of it as a non-negotiable bridge between trusting your supplier and verifying their claims. Without it, you are essentially paying for a promise. With it, you are paying for verified, documented goods. This step is critical for protecting your investment, especially when sourcing from complex supply chains like those in Asia.

The process may seem daunting, but it's a well-established protocol in the textile industry. From knowing which standards to apply, to selecting the right third-party inspector, to understanding how to act on the findings, each step is crucial. At Shanghai Fumao, we not only subject our own shipments to this rigor for key clients but also advise our partners on how to navigate it when working with other suppliers. Let's break down how you can reliably secure this essential document.

Why is a Pre-Payment Fabric Inspection Report Non-Negotiable?

Let's be blunt: the incentive alignment shifts after payment. Before payment, you hold the funds and the power. After payment, you're in a much weaker position to dispute quality issues. A pre-payment inspection report formalizes your right to verification. Its primary purpose is risk mitigation. It identifies problems while the goods are still under the supplier's control and your payment is still in your account. This allows for corrective action—reworking, replacing, or renegotiating—without costly delays, legal disputes, or the nightmare of rejecting goods already on a ship.

The financial logic is clear. The cost of a professional inspection (typically a few hundred dollars) is minuscule compared to the potential losses from a defective shipment: production delays, wasted cutting, inferior final products, and brand reputation damage. Furthermore, the very act of requiring an inspection raises the bar. It signals to your supplier that you are a serious, professional buyer who values quality and due diligence. This often leads to better quality control on their end from the start, as they know the goods will be scrutinized. (Here's a reality check from our side: the best suppliers aren't afraid of inspections; they welcome them as proof of their own standards.)

What are the most critical defects a professional inspection catches?

A professional inspection goes far beyond "it looks okay." It systematically checks for defects that impact production yield and final product quality. The "Big Four" are:

- Shade Variation: Within the same roll (side-to-side, end-to-end) and between different rolls/batches. This can ruin a garment if panels don't match.

- Weaving/Knitting Defects: Holes, slubs, missing yarns, loose threads, barre marks, or inconsistent tension that weaken the fabric or create visual flaws.

- Fabric Dimensions & Yield: Ensuring the fabric width, length per roll, and weight (GSM) are as ordered. Short yards directly steal your profit.

- Hand Feel and Finishing Issues: Improper softening, stiffening, or functional finishes (like waterproofing) that don't meet specifications.

For example, in late 2023, a client requested a pre-shipment inspection for a bulk cotton twill order from another mill. Our recommended third-party service found a 7% incidence of weaving slubs and a 3% variance in GSM. The report provided the evidence needed to secure an 8% price concession before the client released payment, saving thousands and preventing a production disaster.

Can't I just rely on my supplier's own QC report?

This is the most common and costly mistake. A supplier's in-house QC report is useful for internal tracking, but it is not impartial. It is a self-assessment. The conflict of interest is inherent. A professional third-party inspection company is your independent agent. Their business depends on their reputation for accuracy and objectivity, not on securing the next order from the factory. The difference is like having the restaurant's chef tell you the meal is perfect versus having a food critic review it. Always, always use a neutral third party for your pre-payment verification.

What are the Industry Standards for a Professional Fabric Inspection?

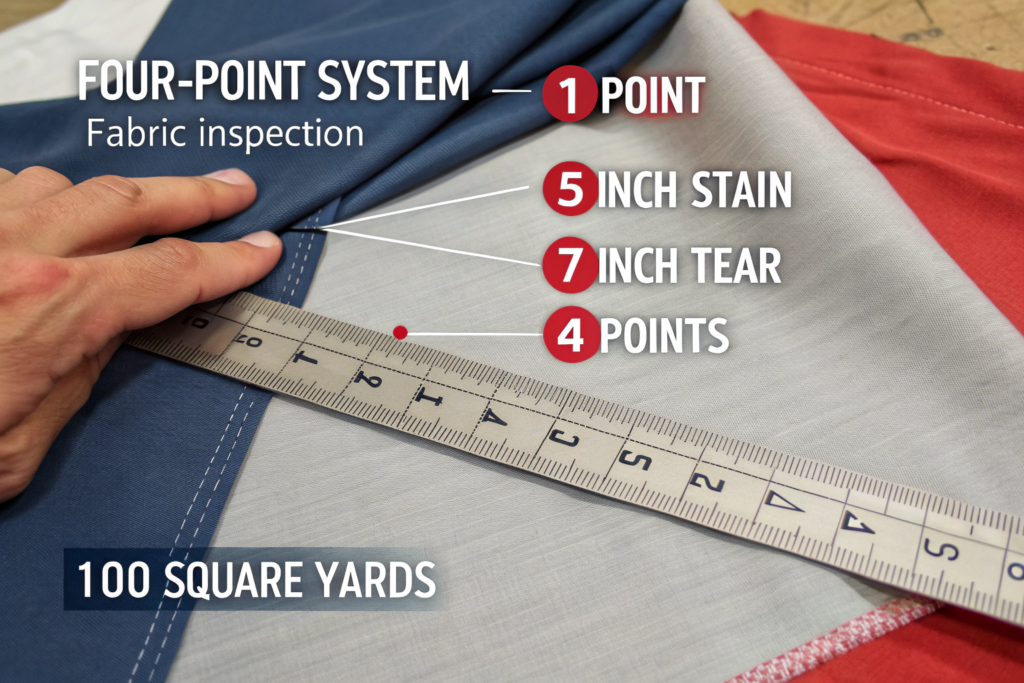

You can't inspect effectively without a rulebook. Industry standards provide the objective, measurable criteria that define what is and isn't an acceptable defect. They turn subjective opinions into quantifiable data. The most widely adopted standard for fabric inspection is the Four-Point System (established by the ASTM and ISO). It's the global lingua franca for defect grading.

How does the Four-Point System work? It assigns penalty points based on the size and severity of a defect found in a linear yard of fabric. The points range from 1 (for a defect 3 inches or less) to 4 (for a defect over 9 inches). The inspector examines a statistically significant sample of the shipment (often following the AQL - Acceptable Quality Level sampling plan, like MIL-STD-105E). They add up all penalty points for the inspected yards, calculate the points per 100 square yards, and compare it to a pre-agreed acceptance limit (e.g., 20 points per 100 sq. yd. is common for apparel). If the score is under the limit, the lot passes. This method is fair, consistent, and universally understood.

How is the AQL (Acceptable Quality Level) used with the Four-Point System?

The AQL determines how much to inspect. It's a statistical sampling plan that balances inspection effort with risk. You define an AQL level (e.g., 2.5 for major defects, 4.0 for minor defects) based on your risk tolerance and the fabric's end-use. Critical medical fabrics might have an AQL of 0.65, while a casual garment fabric might use 4.0. The inspection agency then uses an AQL table to determine how many rolls to select randomly from the shipment and how many yards to inspect from each selected roll. This scientific sampling gives a reliable picture of the whole lot's quality without unrolling every single meter. Understanding how to define AQL levels for your textile orders is a key skill for any serious buyer.

Are there other specialized inspection standards I should know?

Yes, depending on your product. The Four-Point System is the cornerstone, but specific tests are often appended to the report:

- Performance Testing: For functional fabrics, the report should include results from a lab for properties like colorfastness (to washing, light, rubbing), shrinkage, pilling resistance, tensile strength, and water resistance. These tests are done on samples cut during inspection.

- Visual Color Assessment: This should be done under controlled lighting (D65 daylight simulator) to assess shade continuity against an approved lab dip or standard.

- Packaging & Marking: Verifying roll weights, length labels, and shipping marks are correct.

A comprehensive report doesn't just say "passed." It provides all this data. For instance, a client ordering UV protective fabric for sportswear will require the inspection report to include the UPF test results from an accredited lab, not just a visual pass.

How to Choose and Brief a Third-Party Inspection Company?

Not all inspection services are created equal. Your goal is to find a competent, communicative, and truly independent partner. The best choices are often international firms with local presence (like SGS, Bureau Veritas, or TÜV) or highly reputable regional specialists known for textile expertise. Avoid companies recommended solely by your supplier, as their independence may be compromised.

Start by verifying their credentials: Are they ISO 17020 accredited for inspection bodies? Do their inspectors have specific textile training and experience? Ask for sample reports to assess their thoroughness. Crucially, discuss their communication protocol. You need a direct line to the inspector or project manager, not just to go through your supplier. A good inspector will be proactive, sending photos of major defects in real-time during the inspection.

What key points must be in the inspection briefing or checklist?

Your briefing document is your quality blueprint. It must be crystal clear and leave no room for interpretation. It should include:

- Product Specifications: Detailed tech pack reference, including fiber content, construction (weave/knit type), GSM, width, and finished hand feel.

- Approved Standards: Physical standard swatches (lab dips, bulk approval samples) and the correct color standard number.

- Inspection Standards: Specify the defect grading system (e.g., Four-Point System), the AQL levels for major/minor defects, and the pass/fail point score.

- Special Tests: List all required physical/performance tests and the acceptable result ranges (e.g., "Shrinkage after washing: ±3% maximum").

- Logistics Details: Exact factory address, contact person, and the unique ID of the goods to be inspected (like the Purchase Order number).

Providing this briefing in writing is non-negotiable. It aligns everyone and serves as a contractual reference point. We at Shanghai Fumao can provide templates for this, as clear communication is half the battle won.

Should I be present for the inspection?

If possible, yes. A physical visit is the highest level of due diligence. It allows you to see issues firsthand, discuss them immediately with the factory, and understand the context. If you cannot be there, a real-time video call during the inspection is a powerful alternative. Many inspection companies now offer this service. It's the next best thing to being on the ground and allows you to direct the inspector's focus to areas of particular concern. For high-value or first-time orders, this virtual presence is highly recommended. The peace of mind is worth the effort.

What to Do When the Inspection Report Reveals Problems?

Don't panic. An inspection report that finds issues is not a failure; it's the system working as designed. It has given you the information and the leverage you need before payment. Your response should be calm, professional, and based on the data.

First, analyze the severity. Distinguish between critical defects (that make the fabric unusable, like major shade variation or holes) and minor defects (that may be acceptable with a discount or can be worked around in cutting). The report's defect classification and score will guide this. Then, initiate a direct conversation with your supplier, presenting the report as objective evidence, not an accusation. The goal is problem-solving, not blame. Discuss the options: Can the defective rolls be replaced? Can the lot be re-graded and sorted (with a significant discount for the lower-grade fabric)? Or is the entire batch unacceptable?

What are my legitimate negotiation options based on the report?

Your leverage is your unpaid balance. Legitimate options include:

- Replacement of Defective Goods: The supplier replaces the failed rolls or the entire lot. A re-inspection is usually required after replacement.

- Price Discount (Concession): You accept the goods "as is" in exchange for a financial discount that compensates for the lower yield or quality. The discount is often proportional to the defect points or the percentage of defective rolls.

- Sorting and Re-grading: The supplier sorts the shipment into A-grade (good) and B-grade (defective) rolls, with a separate, lower price for the B-grade goods.

The choice depends on your timeline and the nature of the defects. For example, a client in Germany once received a report showing inconsistent brushing on a fleece fabric. The functionality wasn't impacted, only the hand feel varied. We mediated a negotiation where the supplier provided a 5% price concession, which the client accepted, allowing production to proceed on schedule without a costly delay.

When should I walk away from a shipment?

Walking away is a last resort, but sometimes necessary. Red flags include:

- Critical Safety or Performance Failures: Fabric that fails mandatory flammability, lead content, or key performance tests (e.g., waterproofing for rainwear).

- Fraudulent Substitution: The fabric is fundamentally different from what was ordered (e.g., polyester instead of cotton).

- Extensive, Unfixable Defects: Where the defect rate is so high that the effective cost per usable yard exceeds your budget or the supplier is unwilling to offer a fair remedy.

In such cases, use the inspection report as your legal and financial shield to cancel the order and seek a new supplier. This underscores the value of the inspection fee—it saved you from a much larger loss. At Shanghai Fumao, our transparent process is designed to make this scenario extremely rare, but it's vital for you to know your options.

Conclusion

Securing a professional fabric inspection report before payment is the cornerstone of risk management in international textile sourcing. It transforms your purchasing process from an act of faith into a verified transaction. By understanding the standards, selecting an independent inspector, and knowing how to act on the findings, you protect your financial investment, your production schedule, and ultimately, the quality of your final product.

This process doesn't signal distrust; it establishes professional respect and builds a foundation for clearer, more reliable partnerships. It ensures that both you and your supplier are aligned on what constitutes acceptable quality, preventing disputes and fostering long-term collaboration.

Ready to source with confidence? If you are looking for a fabric partner who not only delivers consistent quality but also supports transparent verification processes, let's connect. Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss how we can meet your fabric needs with the quality assurances that give you peace of mind. At Shanghai Fumao, we believe in proving our quality, not just promising it.