You're designing a jacket. It needs to be tough, weather-resistant, and look good. You land on "synthetic fabric" and immediately hit the fork in the road: Polyester or Nylon? Picking the wrong one isn't a small mistake. It's the difference between a jacket that lasts for seasons and one that pills, fades, or loses its shape after a few hikes. This choice defines performance, cost, and customer satisfaction.

Polyester and nylon are both synthetic workhorses, but they're engineered for different priorities. Think of polyester as the resilient, low-maintenance marathon runner—great for consistent endurance. Nylon is the strong, agile sprinter—superior in raw strength and abrasion resistance but requiring more care. At Shanghai Fumao Fabric, we engineer both for outerwear daily. The "best" choice doesn't exist; the right choice depends on your jacket's specific job description.

Let's cut through the marketing fluff. I'll give you the factory-floor breakdown on strength, weather protection, durability, and feel, so you can specify with confidence.

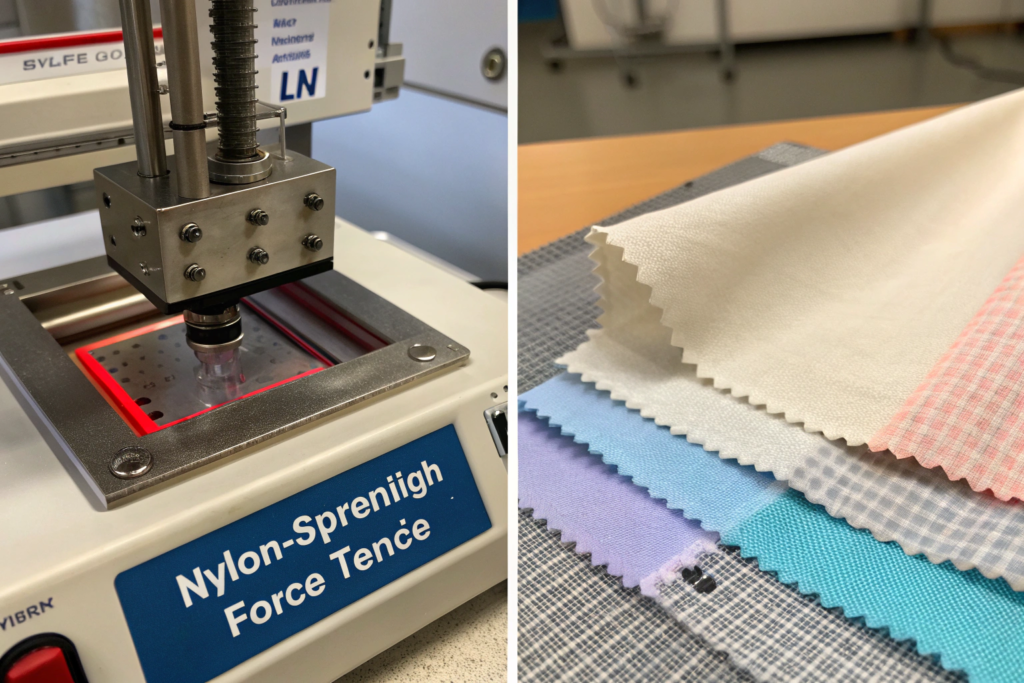

Which Fabric is Stronger and More Durable: Polyester or Nylon?

This is the core question for outerwear that needs to survive the elements. The answer isn't simple, because "durability" means different things. Let's break it down by the science of the fibers.

On a pound-for-pound basis, nylon is stronger. Its molecular chains are more flexible and have higher tensile strength. This means a nylon thread of the same thickness as a polyester thread can withstand more pulling force before it breaks. That's why you find nylon in extreme applications like climbing ropes, parachutes, and heavy-duty luggage. However, polyester has higher tenacity—it's more resistant to stretching under load. It fights to return to its original shape, which is critical for maintaining a garment's silhouette.

How does this translate to jacket performance?

- Abrasion Resistance (Rubbing): Nylon generally wins here. It can better withstand rough surfaces like rock or backpack straps. A heavyweight nylon canvas (e.g., 420D or higher) is the go-to for mountaineering or workwear where scraping is constant.

- Pilling & Fuzzing: Polyester often has the edge. It's more resistant to the surface fuzzing and balling that comes from friction. A polyester fleece or soft-shell will maintain a cleaner look longer than a nylon equivalent. This is a key consideration for urban outerwear or apparel where aesthetic longevity matters.

- UV Degradation: This is polyester's knockout punch. Nylon degrades and loses strength significantly faster when exposed to prolonged sunlight. Polyester has much higher inherent UV resistance. For jackets meant for hiking, sailing, or any extended sun exposure, polyester is the durable choice. The Outdoor Industry Association materials library provides deep dives into durability testing for performance textiles.

| Quick Reference: Durability Face-Off | Characteristic | Polyester | Nylon | Best For |

|---|---|---|---|---|

| Tensile Strength | High | Higher | Load-bearing components | |

| Abrasion Resistance | Good | Excellent | Knees, shoulders, backpacks | |

| Pilling Resistance | Excellent | Good | Urban wear, fleece, soft-shell | |

| UV Resistance | Excellent | Poor | Sun-exposed outerwear |

What about blended fabrics?

You don't always have to choose. A common and effective strategy is blending. A 70% polyester / 30% nylon taffeta, for example, combines polyester's UV and color stability with nylon's added tear strength. We develop these blends at Shanghai Fumao to hit specific price-performance targets for our clients.

How Do Polyester and Nylon Handle Water and Weather?

Outerwear's primary job is protection. Both fibers are naturally hydrophobic (water-repelling), but their behavior with water differs in critical ways. This affects everything from waterproofing to drying time and long-term performance in wet conditions.

Polyester is more hydrophobic. It absorbs less than 1% of its weight in moisture. This means water stays on the surface, and the fabric dries incredibly quickly. Nylon, while still water-resistant, absorbs slightly more moisture (around 4%). This means it can feel damp longer and is slightly heavier when wet. However, this slight absorption can be an advantage for comfort in non-rainy conditions, as it can wick slight perspiration.

Which is better for waterproof membranes and coatings?

Both can be laminated with membranes like Gore-Tex or coated with PU/PVC. However, the base fabric matters:

- For Membrane Lamination (e.g., 3-Layer Gore-Tex): Nylon is often preferred for the face fabric because its superior strength allows for lighter, thinner, yet more tear-resistant constructions. That's why you see ultra-lightweight 10D or 15D nylon in high-end rain shells.

- For PU/PVC Waterproof Coatings: Polyester is often the substrate of choice. Its low moisture absorption means the coating bonds very consistently and doesn't have to fight moisture trapped in the fiber. It also resists hydrolysis (breakdown from water and heat) better than nylon, leading to a longer-lasting waterproof coating.

A client making fishing apparel switched from a coated nylon to our coated polyester fabric in 2023. Their failure rate from delamination (coating peeling off) dropped by over 60% because the polyester base provided a more stable platform. Resources like Gore-Tex Fabric Technology Portal explain how base fabric selection impacts finished laminate performance.

What about wind resistance and breathability?

Both can be woven into tight, windproof fabrics. Breathability is far more dependent on the fabric construction (weave/knit density) and any membrane than on the fiber itself. However, because polyester dries faster, a damp polyester inner layer (like in a soft-shell) will feel less clammy than damp nylon.

What Are the Differences in Dyeing, Color, and Aesthetics?

The jacket has to perform, but it also has to sell. Color is where polyester and nylon diverge dramatically, impacting both the final look and the cost to achieve it.

Polyester is the champion of color vibrancy and stability. It is dyed with disperse dyes at high temperatures, which bond deeply into the fiber. The result is brilliant, saturated colors that have exceptional colorfastness to washing and light. This is why athletic wear and fashion outerwear with bold, long-lasting colors are predominantly polyester. Its UV resistance also prevents fading.

Nylon is more challenging. It is typically dyed with acid dyes. It can achieve deep, rich colors, but it is generally less colorfast than polyester, especially to UV light (prone to fading). Achieving consistent, level dyeing on nylon can be trickier and sometimes more expensive. However, nylon takes a softer, more luxurious dye that can give it a richer, deeper "hand" — a reason it's favored for high-end luggage and soft-shells where a premium feel is key.

How does this affect design and cost?

- Printing: Sublimation printing (for all-over prints) works only on polyester. The ink bonds with the polymer. You cannot effectively sublimate print nylon. This makes polyester the undisputed choice for complex, photographic, or gradient-heavy printed outerwear.

- Color Matching: Polyester offers more predictable, repeatable color batch-to-batch. Nylon can be more susceptible to batch variations due to differences in dye uptake.

- Final Aesthetic: Nylon often has a softer, slightly warmer drape. Polyester can feel crisper or have a more "technical" sheen, though modern microfilament polyesters (like our high-performance fabrics) can be made incredibly soft and silk-like.

For a streetwear brand launching a line of vibrant, color-blocked anoraks, polyester was the only viable choice for both color intensity and printability. We used a 75D polyester taffeta with a matte finish to give it a premium, non-shiny look.

How Do You Choose Based on End-Use and Cost?

Now, let's get practical. With all these technical differences, how do you make the final call? You match the fiber's inherent strengths to your garment's specific mission and budget. Asking the right questions will lead you to the right answer every time.

Here is a simple decision framework we use with our clients at Shanghai Fumao:

-

What is the PRIMARY threat?

- Abrasion & Tears (e.g., climbing, workwear): Lean toward Nylon or a nylon-rich blend.

- Sun & UV Exposure (e.g., sailing, hiking): Lean toward Polyester.

- Heavy, Consistent Rain (coated jackets): Polyester for coating longevity.

- Ultra-Lightweight Packability (high-end rain shells): Nylon for strength at low deniers.

-

What is the AESTHETIC and COLOR need?

- Vibrant Colors/All-Over Prints: Polyester is mandatory.

- Premium, Deep Hand-Feel: Nylon often wins.

- Matte vs. Shiny Finish: Both can be engineered either way; specify with your supplier.

-

What is the BUDGET?

- Generally, for equivalent weights and constructions, nylon filament is more expensive than polyester filament due to raw material (petrochemical) costs. This cost difference can influence choice for price-sensitive large-volume orders.

Can you give real-world jacket examples?

- The Urban Rain Jacket: Polyester. Prioritizes color fastness, print potential, quick drying, and resistance to city grime and UV fading from window exposure. A 190T polyester pongee with a PU coating is a classic, cost-effective choice.

- The Technical Ski Shell: Nylon. Prioritizes extreme lightweight strength, abrasion resistance at contact points (ski edges, lift chairs), and reliable membrane performance. Often uses a 20D-40D ripstop nylon face fabric.

- The Softshell Jacket: Could be either. A polyester softshell offers better pilling resistance. A nylon softshell might offer a slightly softer hand and better stretch recovery. It's a nuanced choice.

For a detailed cost-benefit analysis on material selection, business-focused blogs like Apparel Entrepreneurship often discuss making smart fabric choices to balance performance and margin.

Conclusion

Choosing between polyester and nylon for outerwear isn't about finding a "better" fabric; it's about matching an engineered material to a specific set of performance demands. Polyester brings superior color, UV resistance, and quick-drying reliability to the table. Nylon offers unmatched strength-to-weight ratio and abrasion resistance. Understanding this distinction allows you to design with intention, creating garments that genuinely perform as promised.

Blurring the lines with advanced blends and finishes is where modern fabric innovation thrives, but it all starts with this fundamental choice. Getting it right builds your brand's reputation for quality; getting it wrong leads to returns and disappointment.

You don't have to navigate this technical maze alone. At Shanghai Fumao Fabric, we combine deep material science with practical manufacturing experience. Let us help you select or develop the perfect polyester, nylon, or hybrid fabric for your next outerwear collection. Contact our Business Director, Elaine, for a technical consultation: elaine@fumaoclothing.com.