If you’re sourcing fabrics for your next collection, you’ve probably seen Tencel™, Modal, and Viscose Rayon all marketed as “eco-friendly,” “silky smooth,” and “breathable.” But when your supplier quotes you, the price difference between them can be huge—so what are you really paying for? Are they just fancier names for the same thing, or do they actually perform differently in production and on the rack? As a fabric expert based in Keqiao, I see brands make costly mistakes here every season, choosing the wrong fiber based on a marketing tag rather than technical reality.

The core difference lies in their raw material source, manufacturing process, and environmental footprint. Tencel™ (Lyocell) is made from wood pulp using a closed-loop solvent spinning process, producing a strong, durable fiber with high moisture-wicking ability. Modal is also from wood pulp but uses a modified viscose process, resulting in a softer, more stretchable fiber ideal for lightweight knits. Viscose Rayon, the traditional type, uses a more chemically-intensive process that can vary widely in environmental impact, and it generally offers a luxurious drape at a lower cost but with less durability when wet. Think of them as cousins: same plant-based origin, but with different “upbringings” that define their character.

Let’s get real. In 2023, a Swedish sustainable activewear brand came to us with a problem: their viscose leggings were pilling and losing shape after a few washes. They thought switching to any “eco” cellulose fiber would solve it. We had to explain that their high-intensity use case needed Tencel™’s tenacity, not Modal’s ultra-softness. We ran a side-by-side test in our lab, and the Tencel™ blend retained 40% more strength after 50 wash cycles. This isn’t about good or bad fibers; it’s about right application. This guide will cut through the greenwashing and give you the supplier’s perspective on how these fibers behave from spinning to sewing to store.

What are the raw materials and production processes?

At the heart of the confusion is this: all three start with cellulose, usually from trees like beech, eucalyptus, or bamboo. The magic—and the massive difference in environmental impact and fiber quality—happens in how that pulped wood is transformed into a spinnable fiber. The process dictates everything from molecular structure to factory wastewater.

The journey from tree to thread involves dissolving pulp and then regenerating it as fiber. Viscose Rayon uses the traditional viscose process: pulp is treated with carbon disulfide and sodium hydroxide, creating a viscous solution spun into a sulfuric acid bath. This process is more open and can involve more chemical recovery challenges. Modal uses a modified, higher-quality viscose process with more refined pulp and often stronger concentration controls, yielding a higher-tenacity fiber. Tencel™ (Lyocell), however, uses the NMMO (N-Methylmorpholine N-oxide) solvent spinning method, a closed-loop system where over 99% of the solvent is recycled and reused. This isn’t just a technical detail; it’s the reason Tencel™ commands a premium and has a fundamentally different physical structure.

How does the closed-loop process make Tencel™ unique?

The Tencel™ Lyocell process is a game-changer in man-made cellulosics. Here’s why it matters for you as a buyer: The NMMO solvent is non-toxic and almost entirely recovered. This means the environmental footprint is significantly lower regarding water pollution and chemical use. But the real product advantage is in the fiber itself. The closed-loop method allows for a more controlled, direct dissolution of pulp. This results in a fiber with a smoother, more aligned molecular structure and a rounder cross-section.

This structure gives Tencel™ its signature performance: exceptional wet strength (it’s almost as strong wet as dry, unlike viscose which loses up to 50% strength), high moisture absorption and wicking, and a unique ability to develop a soft peach-skin feel (called “fibrillation”) under specific finishing treatments. For manufacturers, this means better runnability on knitting machines and less breakage. For brands, it translates to durable garments that handle washes well. When you’re evaluating how to source truly sustainable closed-loop cellulose fibers, looking for the Tencel™ brand (by Lenzing) or Lyocell with credible certification is key. At Shanghai Fumao, we use Tencel™ LF (licensed fiber) in many of our advanced knits, and the consistency from batch to batch is unmatched, which saves massive headaches in production.

Why are Modal and Viscose Rayon often grouped together?

Modal and Viscose are both produced via the viscose method, which is why they share core characteristics like a luxurious hand feel, excellent drape, and high moisture absorption. However, Modal is essentially a premium, high-strength viscose. It typically uses beechwood pulp from sustainably managed forests, and the process modification involves using a higher concentration of cellulose and different stretching techniques during spinning.

This creates a fiber that is finer and more uniform than standard viscose, giving it greater softness, better color vibrancy, and improved strength, especially when wet. It’s why Modal is the go-to for high-end underwear, luxury t-shirts, and soft bedding. However, the environmental impact of Modal can vary widely depending on the manufacturer’s practices. It’s crucial to ask your supplier for specifics. Is their Modal from Lenzing (which has its own stringent eco-protocols) or another source? Understanding the environmental certifications for viscose and modal fibers (like EU Ecolabel, FSC, or STeP) is not just for marketing—it’s your due diligence. We always provide mill certification sheets to our clients because a US client last year almost faced a compliance issue when their “eco-modal” couldn’t be traced back to a certified forest.

How do they perform in fabric and during garment making?

You can have the most sustainable fiber on paper, but if it’s a nightmare to cut, sew, or washes into a rag, it’s worthless for your brand. The performance divergence between these three becomes starkly clear on the factory floor and in quality control testing.

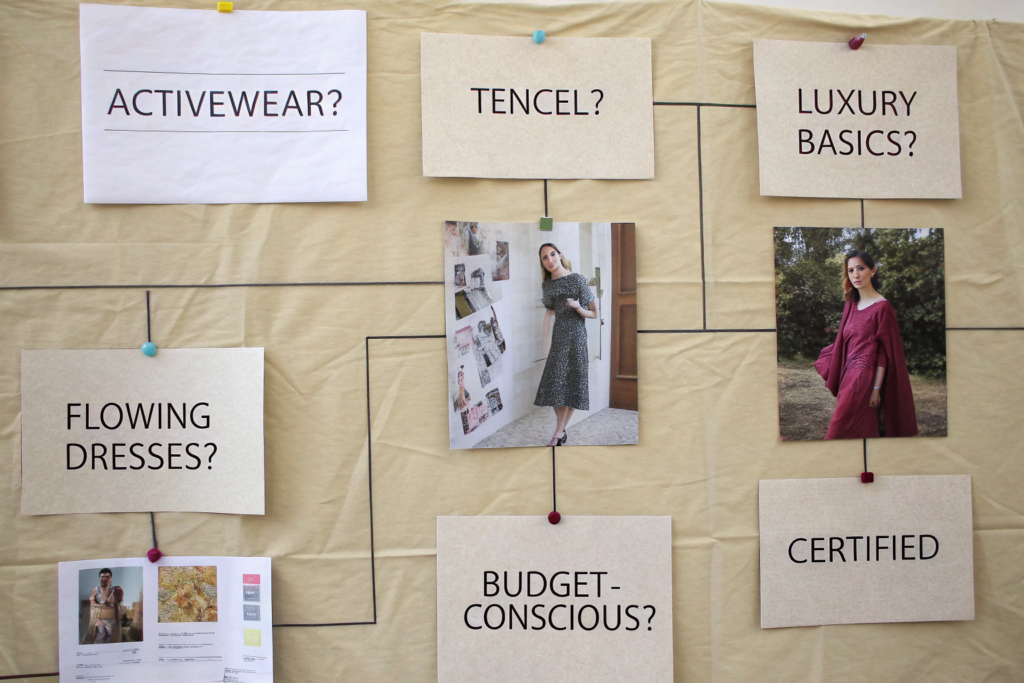

In general, Tencel™ leads in durability and moisture management, making it ideal for activewear, denim, and structured wovens. Modal excels in softness, stretch recovery, and luster, perfect for intimate apparel and soft knits. Viscose Rayon offers unbeatable drape and richness at a competitive price, great for flowing dresses, linings, and blouses. But these are generalizations. The blend ratio, yarn construction, and fabric finish dramatically alter the final behavior. For instance, a 50/50 Tencel™-Modal blend can give you the best of both worlds: strength and sublime softness.

Which fiber is more durable and colorfast?

Let’s talk numbers. In our CNAS-accredited lab, we regularly test for abrasion resistance (Martindale test), tensile strength, and colorfastness to washing and light.

- Tencel™: Consistently scores highest. Its inherent fiber strength translates to excellent abrasion resistance. Color uptake is also superior due to its smooth surface and high porosity, leading to vibrant, long-lasting dyes. A 100% Tencel™ woven we tested retained over 90% of its color intensity after 30 home washes.

- Modal: Shows good durability for its weight, especially in wet states compared to standard viscose. Colorfastness is generally very good, offering rich, deep shades. However, its extreme softness can make finer Modal knits more prone to pilling under friction than Tencel™.

- Viscose Rayon: Has the lowest wet strength, meaning it requires more careful handling during wet processing (dyeing, washing) and garment care. Color absorption is excellent, giving it a deep, luxurious color, but some lower-quality viscoses can experience more color fading over time. The key is to work with a supplier who understands best practices for dyeing cellulosic fabrics to ensure colorfastness. We control this by partnering with dye houses that use reactive dyes and optimized fixation processes, which we then verify with our lab tests before shipping.

How do they handle sewing, cutting, and finishing?

This is where your factory’s feedback comes in. We’ve had production managers call us with both praise and complaints based on the fiber.

- Sewing: Tencel™ fabrics, being stronger, generally run through machines well with less fear of seam slippage. Modal’s stretch and recovery are great but require appropriate needle size and stitch tension to prevent puckering. Viscose, especially in lightweight constructions, can be slippery and may require skilled operators and tissue interlining during sewing.

- Cutting: Modal and Viscose knits can be stretchy on the cutting table, requiring precise layering and weights. Tencel™ wovens are typically more stable.

- Finishing: This is Tencel™’s secret weapon. Through controlled enzymatic washing, it can develop that coveted soft peach-skin touch (micro-fibrillation). Modal achieves its signature softness through chemical softening agents. Viscose often gets a liquid ammonia finish to enhance luster and reduce shrinkage. (Here’s a pro tip from our finishing plant: never use the same enzymatic wash recipe for Tencel™ and Modal—you’ll ruin the Modal’s hand.) For brands wanting to innovate, exploring special finishing techniques for Tencel™ fabrics can add significant value.

What are the cost and sustainability trade-offs?

The price tag tells a story of process complexity, raw material cost, and brand investment. Sustainability is no longer a single checkbox; it’s a multi-layered assessment from forest to finish. You can’t have an honest conversation about cost without talking about ecological cost, and vice versa.

On a per-kilogram basis, the typical price hierarchy is: Standard Viscose < Modal < Tencel™. However, this is misleading if you only look at the raw fiber cost. You must consider the Total Cost of Use: fiber cost, production yield (less waste from breakage?), garment performance (fewer returns?), and brand equity (can you charge a premium?). A cheaper viscose that leads to a 5% higher defect rate in sewing and garners customer complaints about shrinkage is far more expensive in the long run.

Is the premium for Tencel™ justified for my product?

The answer depends entirely on your product’s value proposition and use case. Justified for: Performance apparel (yoga wear, travel clothing), premium denim, linen-like summer wovens, and any product where durability, moisture management, and a strong sustainability story are central to the brand and justify a higher price point. The Tencel™ brand itself has strong consumer recognition in key markets like Europe.

Possibly Overkill for: Fast-fashion items with a very short intended lifespan, lightweight linings where extreme drape is the only requirement, or products where the final consumer cannot perceive the difference in hand feel (e.g., heavily coated fabrics). Sometimes, a high-quality Modal or a responsibly sourced viscose is the more commercially savvy choice. We helped an Australian boutique brand launch a capsule collection by using a Tencel™-Linen blend for their hero pants, while using a certified viscose for the accompanying blouse, perfectly balancing cost and impact.

How do I verify “sustainable” claims for each fiber?

Greenwashing is rampant. Protect your brand by asking your supplier for verifiable proof. Don’t just accept “eco-friendly” on an invoice.

- Traceability: Ask for the fiber source. Is the wood pulp FSC (Forest Stewardship Council) or PEFC certified? Can they provide a chain-of-custody document?

- Process Certifications: For Tencel™, the closed-loop process is certified with the EU Ecolabel. For Modal and Viscose, look for manufacturers certified with standards like STeP by OEKO-TEX® (Sustainable Textile Production) or those adhering to the EU BAT (Best Available Techniques) for viscose manufacturing.

- Output Certifications: The final fabric should be tested for harmful substances (OEKO-TEX® Standard 100) and may carry specific labels like the Lenzing Eco Soft logo for their Modal.

We make this transparent at Shanghai Fumao. Our recycled and cellulose fabrics come with a digital QC tag that links to test reports and material origin summaries. It’s the kind of due diligence that saved a German client during a supply chain audit last quarter. They were sourcing what they thought was sustainable fabric, but our competitor couldn’t provide paperwork. They switched to us, and our pre-compiled dossier made their compliance manager’s job easy. Researching global standards for sustainable cellulose fiber production is time well spent before you place an order.

How should I choose for my specific product line?

This is the decision matrix. There’s no “best” fiber, only the “best for your specific application.” Your choice should be a strategic blend of technical requirements, cost constraints, brand positioning, and target market expectations.

Think like an engineer and a marketer simultaneously. Break down your product brief: What is the primary function? (e.g., Wick sweat, feel luxurious, drape fluidly). What is the construction? (e.g., Dense knit, lightweight woven, heavy denim). Who is the end consumer and what do they value? (e.g., Durability, softness, price, eco-story). What is the price bracket? Only then can you match the fiber properties to your needs.

Can I blend them for better performance and cost?

Absolutely, and this is where fabric development gets exciting. Blending is the smart way to optimize performance and cost.

- Tencel™ + Cotton: Adds strength, luster, and drape to cotton. Very common in shirting and denim. Improves color vibrancy.

- Modal + Cotton / Spandex: Creates the ultimate soft, stretchy jersey for t-shirts and underwear. Modal enhances softness and reduces pilling compared to pure cotton.

- Viscose + Polyester: A workhorse blend. Polyester adds durability, wrinkle resistance, and lowers cost, while viscose provides moisture absorption and a better hand feel than pure polyester.

- Tencel™ + Linen: A fantastic summer fabric. Tencel™ reduces linen’s inherent wrinkles and adds a soft, smooth touch, elevating the luxury feel.

We developed a best-selling fabric for a French brand: a 55% Tencel™, 40% Recycled Polyester, 5% Spandex double knit. The Tencel™ gave it a cool, dry hand and eco-cred, the rPoly added durability and recycled content, and the spandex provided comfort stretch. It hit all their targets. Experimenting with innovative fabric blends for performance apparel is a core part of our R&D service.

What questions must I ask my fabric supplier?

Don’t go in blind. Arm yourself with these questions to separate true partners from order-takers:

- “Can you provide the fiber origin and mill certification for this Tencel™/Modal/Viscose?”

- “What are the standard shrinkage and colorfastness test results for this specific fabric composition?”

- “Do you have a recommended care label for garments made from this fabric?” (Their answer reveals deep practical knowledge.)

- “Can you share a swatch of this fabric after 5 home wash cycles?” (A good supplier will have done this testing.)

- “What are the minimum order quantities (MOQ) for this fabric in custom colors?”

Asking these questions not only gets you better information but also signals to the supplier that you are a knowledgeable, serious buyer. When you work with Shanghai Fumao, you get these answers upfront. Our technical sheets include all this data because we believe an informed customer is our best partner. We’re not just selling meterage; we’re co-developing a successful product with you.

Conclusion

Tencel™, Modal, and Viscose Rayon are distinct players in the cellulosic fiber league, each with a unique profile shaped by its production process. Tencel™ stands out for its closed-loop sustainability and robust performance, Modal reigns supreme in softness and stretch, while Viscose Rayon offers classic drape and accessibility. The “best” choice is never generic; it’s the one that aligns perfectly with your garment’s function, your brand’s values, your production realities, and your customer’s expectations.

Making the right choice requires looking beyond marketing buzzwords. It demands a technical understanding of fiber properties, a critical eye for verifiable sustainability credentials, and a collaborative partnership with a fabric supplier who can guide you from swatch to shipment. By matching the fiber’s inherent strengths to your product’s demands, you invest in quality, reduce production risks, and build a more credible and compelling collection.

If you’re navigating these choices for an upcoming line and want a partner who can provide not just the fabric but also the expertise, let’s connect. At Shanghai Fumao, we live in the details of fiber science and fabric performance. We can help you A/B test swatches, analyze cost-performance trade-offs, and source the right certified materials to bring your vision to life responsibly and successfully. Ready to develop fabrics that truly work for your brand? Contact our Business Director, Elaine, for a consultation on your next project. Reach her at elaine@fumaoclothing.com. Let’s create something exceptional together.