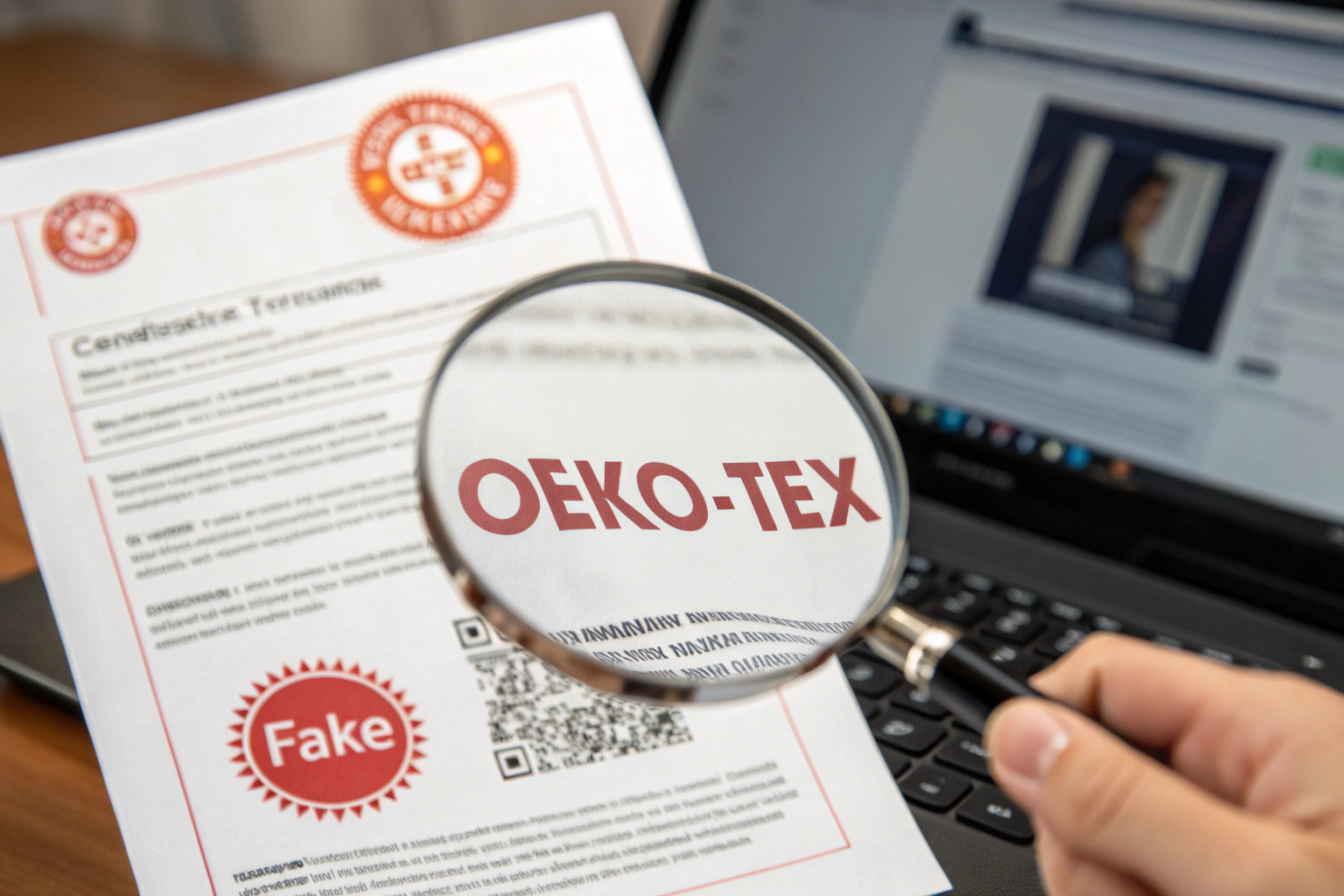

Two weeks ago, I received an urgent call from a Miami-based swimwear brand. They'd been working with a "certified" factory in Bangladesh for six months. Their new collection was ready to ship - 15,000 units of children's swimwear. As a final check, they asked the factory for the OEKO-TEX® batch test reports. What they received was a PDF that looked...off. The certificate number format was wrong. The issuing institute logo was pixelated. When they questioned it, the factory manager became defensive, then disappeared. They flew me in to investigate. What we discovered was a sophisticated fraud operation: the factory had one legitimate certificate from 2019, and had been Photoshopping it for every new client since. The "OEKO-TEX® certified" swimwear contained lead and phthalates at levels that would have triggered immediate CPSIA violations in the US. The brand's entire season - and potentially their business - was saved by one simple verification step they almost skipped.

This isn't rare. In my 20 years supplying to global brands, I've seen every type of certificate fraud: expired certificates presented as current, legitimate certificates from different companies, Photoshopped documents, certificates for wrong product classes, testing institute impersonations. The scary truth is that fake OEKO-TEX® certificates are now more common than most brands realize. But here's the good news: verification isn't complicated if you know what to look for. This guide will give you the exact, step-by-step forensic process we use at Fumao Clothing to verify every certificate - whether it's ours or a competitor's. I'll show you how to spot fakes in under 5 minutes, what questions to ask that fraudsters can't answer, and how to build verification into your sourcing workflow so you're never fooled.

What are the most common types of certificate fraud?

Before you can verify, you need to know what you're looking for. Based on our investigations for clients, here are the five most prevalent fraud types:

1. The "Expired & Reused" (Most Common - 45% of fakes)

A legitimate certificate that has expired but continues to be presented as current. OEKO-TEX® certificates are valid for one year. We see factories using certificates 2-3 years old, simply changing the dates in PDF editors.

2. The "Company Mismatch" (25% of fakes)

A legitimate certificate from a different company - often a sister factory or trading partner - presented as their own. The certificate is real, but the company name doesn't match.

3. The "Photoshop Special" (15% of fakes)

Digital alteration of a legitimate certificate. Common edits include:

- Changing company names and addresses

- Altering certificate numbers

- Modifying validity dates

- Adding or removing product scope

4. The "Class Misrepresentation" (10% of fakes)

Presenting a certificate for a different product class. Most common: showing Class III (no skin contact) or Class IV (decoration) certificates for skin-contact products.

5. The "Testing Institute Impersonation" (5% of fakes)

Certificates from non-accredited testing companies that mimic OEKO-TEX® branding. Only 18 institutes worldwide are authorized to issue OEKO-TEX® certificates.

Each type requires different detection methods. Last month, we helped a Dutch brand uncover a "Company Mismatch" fraud. The factory showed a legitimate certificate, but database verification revealed it belonged to their dyeing subcontractor, not the garment factory. The factory had no certification of their own.

How can you spot an expired certificate immediately?

Expired certificates have telltale signs:

- Date discrepancies: Issue date more than 12 months old

- No renewal evidence: OEKO-TEX requires annual renewal; check for multiple certificates over time

- Outdated standard references: OEKO-TEX standards update yearly; old certificates reference outdated versions

- Missing surveillance audit marks: Renewed certificates show surveillance audit dates

Quick check: Ask for certificates from the last three years. A legitimate certified factory will have annual certificates showing continuous certification. If they only have one certificate from several years ago, it's a major red flag.

What about "borrowed" certificates from trading companies?

This is particularly common with trading companies that don't own factories. They show the factory's certificate as their own. Verification steps:

- Check the certificate holder name matches the company you're contracting with

- Verify the address matches the factory location

- Ask for authorization letter from the certificate holder allowing its use

- Confirm direct relationship between trading company and factory

We recently caught a trading company using our certificate to sell fabrics they weren't authorized to sell. They'd bought one batch from us, kept the certificate, and were using it to sell inferior fabrics from other mills. The certificate was legitimate but being used fraudulently.

What is the step-by-step verification process?

Verification is a forensic process, not a quick glance. Here's our 7-step verification protocol developed over thousands of certificate reviews:

Step 1: Database Verification (Non-negotiable)

Go directly to the OEKO-TEX® certification database: certificate.oeko-tex.com

- Enter the certificate number exactly as shown

- Check: Company name matches exactly (including spelling and legal entity)

- Check: Address matches the factory location

- Check: Validity shows "valid" status with current dates

- Check: Product scope matches what you're buying

Step 2: Certificate Number Format Check

Legitimate OEKO-TEX® certificate numbers follow specific formats:

- Usually begins with country code (CN for China, DE for Germany, etc.)

- Followed by testing institute code (e.g., 01 for TESTEX Zurich)

- Then unique identifier numbers

- Example valid format: CN 01 123456

If the number looks random or doesn't match standard formats, be suspicious.

Step 3: Issuing Institute Verification

Only 18 institutes worldwide can issue OEKO-TEX® certificates. Common legitimate ones:

- TESTEX (Switzerland, various locations)

- Shanghai CTI (China)

- Bureau Veritas (France)

- Hohenstein (Germany)

- Intertek (Various)

Check the institute logo and name match the accredited list on OEKO-TEX.com.

Step 4: Document Forensic Analysis

Examine the PDF for signs of alteration:

- Font consistency: Use "Properties" in Adobe to check embedded fonts

- Pixelation: Zoom to 400% to check for blurry text or logos

- Layer analysis: Check if document has been edited in Photoshop

- Metadata: Check creation/modification dates in document properties

Step 5: Batch Report Cross-Reference

Legitimate certification requires batch-specific testing. Ask for:

- Test reports for recent production batches (last 3 months)

- Reports should reference the master certificate number

- Testing dates should be within certificate validity period

- Lab stamps and signatures should be present

Step 6: Product Class Verification

Ensure the certificate covers the correct product class for your application:

- Class I: Babies (0-3 years)

- Class II: Direct skin contact

- Class III: No direct skin contact

- Class IV: Decoration materials

Step 7: Scope Match Verification

The certificate's product description should match what you're buying:

- Fiber content (cotton, polyester, blends)

- Product type (knitted, woven, non-woven)

- Treatments included (printing, coating, etc.)

- Any exclusions or limitations noted

What specific details should you examine in the PDF?

When analyzing the certificate PDF, look for these technical details:

Text and Font Analysis:

- Select text - does it highlight as text or as an image?

- Check font names in Properties - are they standard (Arial, Times) or unusual?

- Look for font weight inconsistencies within the same document

Logo and Image Quality:

- OEKO-TEX logo should be vector-based (crisp at any zoom level)

- Testing institute logos should be clear and properly aligned

- Background watermarks should be subtle and consistent

Digital Signature Verification:

- Modern OEKO-TEX certificates include digital signatures

- Check if the signature validates in Adobe Reader

- Hover over signature to see validation status

Metadata Examination:

- File → Properties → Description

- Check creation software (should be from testing institute, not Photoshop)

- Look at modification history

- Check embedded fonts match what's displayed

We caught a sophisticated fake last quarter where everything looked perfect except the font metadata. The certificate claimed to be from TESTEX but was created in "Adobe Photoshop CC 2023" - a dead giveaway since testing institutes use specialized document systems, not Photoshop.

How do you verify batch test reports?

Batch reports are harder to fake than certificates. Look for:

1. Laboratory Letterhead: Official stationery of the testing institute

2. Reference Numbers: Should reference the master certificate number

3. Testing Dates: Recent (within 3 months for active production)

4. Sample Description: Detailed description matching your product

5. Test Results: Actual numerical results, not just "pass/fail"

6. Signatures/Stamps: Authorized signatories from the lab

7. Method References: Specific test methods used (ISO, EN, etc.)

Ask for reports from multiple batches over time. A legitimate factory will have consistent testing history. If they only have one report from months ago, question what's happened since.

What questions should you ask the factory?

Documents can be faked, but operational knowledge is harder to fake. Ask these technical questions:

Question 1: "Can you walk me through what happens when a new chemical arrives at your factory?"

- Good answer: "It goes to our chemical management team who checks the SDS against our RSL, runs a preliminary test if needed, and only approves it if it passes all checks."

- Red flag: "Our chemical supplier provides certificates, we trust them."

Question 2: "How do you prevent cross-contamination between OEKO-TEX® and non-certified production?"

- Good answer: "We have dedicated lines for certified production, separate chemical storage, and documented cleaning protocols validated by testing."

- Red flag: "We clean the machines between runs."

Question 3: "Who is your OEKO-TEX® compliance officer, and can I speak with them?"

- Good answer: Immediate introduction to a technical person with detailed knowledge.

- Red flag: "The sales manager handles all certification questions."

Question 4: "What was your last non-conformance, and how did you address it?"

- Good answer: Specific example with documented corrective actions.

- Red flag: "We've never had any issues." (Statistically improbable)

Question 5: "Can you show me your chemical inventory management system?"

- Good answer: Digital system showing approved chemicals, usage tracking, and SDS management.

- Red flag: Paper records or no system visible.

When we ask these questions during supplier audits, we can immediately separate truly certified factories from those with just paperwork. The depth of operational knowledge reveals everything.

How do you verify during a factory visit?

If you can visit the facility, look for these physical signs:

Certification Display:

- OEKO-TEX® certificate prominently displayed (not just in sales office)

- Current certificate (check dates)

- Certificates for different product classes if applicable

Production Segregation:

- Dedicated areas for certified production

- Separate chemical storage for certified materials

- Clear labeling of certified vs non-certified materials

Documentation Systems:

- Quality control records accessible and organized

- Batch traceability systems visible

- Testing equipment on-site (pH meters, etc.)

- Training records for chemical handling

Worker Knowledge:

- Random workers can explain basic safety procedures

- Chemical handling protocols are followed

- Protective equipment is properly used

We accompanied a US brand to audit a potential supplier last month. The factory had beautiful certificates in the showroom, but on the production floor, certified and non-certified fabrics were mixed together, workers couldn't explain chemical procedures, and there were no dedicated lines. The certificates were technically valid but meaningless given the operational reality.

What about virtual factory tours?

For remote verification, request:

- Live video tour of production areas (not pre-recorded)

- Document camera session showing certificate originals, not scans

- System demonstrations of their digital management systems

- Interviews with technical staff not just sales

During virtual tours, ask them to:

- Show certificate hanging on wall (proves physical existence)

- Zoom in on dates and details

- Show chemical storage areas

- Demonstrate testing equipment operation

A German brand we work with conducts all initial verifications virtually. Their checklist includes 27 specific items to view during the tour. Factories that can't or won't provide this level of access are immediately disqualified.

What are the red flags in supplier behavior?

Sometimes the warning signs aren't in documents but in how suppliers act:

Red Flag 1: Evasiveness About Details

When you ask specific questions about testing parameters or limits, they give vague answers like "It's all certified, don't worry." A legitimate supplier should be able to discuss specific substances and limits.

Red Flag 2: Resistance to Independent Verification

If a supplier gets defensive or tries to talk you out of third-party testing ("too expensive," "will delay shipment"), be very suspicious. We actually encourage clients to do occasional spot checks - it validates our system.

Red Flag 3: Pressure to Skip Due Diligence

"We need to confirm the order today to lock in the price." "The certification is being renewed but trust us." Any pressure to bypass verification is a major warning.

Red Flag 4: Inconsistency Between Documents

The company name on the certificate doesn't match the business license. The address is different. The product description is generic while your order is specific.

Red Flag 5: Only One Point of Contact

All communication goes through sales. Requests to speak with technical or compliance staff are denied or delayed.

Red Flag 6: Pricing Too Good to Be True

OEKO-TEX® certification has real costs: testing fees, system investments, higher material costs. If their price is suspiciously low, they're likely cutting corners somewhere.

A UK brand shared their experience: their previous supplier had all the "right" documents but always shipped at the last possible minute, giving no time for pre-shipment testing. When problems emerged later, they realized this was intentional - to prevent discovery until payment was complete.

How do pricing inconsistencies signal potential fraud?

True OEKO-TEX® certification adds significant costs:

- Testing fees: $500-$2,000 per product depending on complexity

- Annual certificate fees: $2,000-$5,000+

- System investments: Dedicated equipment, training, documentation systems

- Material premiums: Certified raw materials cost 10-30% more

- Production efficiency loss: Dedicated lines reduce machine utilization

If a supplier's price for "OEKO-TEX® certified" fabric is within 10-15% of non-certified market prices, investigate thoroughly. The math likely doesn't work unless they're cutting corners.

We recently analyzed a competitor's pricing that raised red flags. Their "certified" organic cotton jersey was priced at $3.20/meter when our truly certified version cost $4.85/meter. Investigation revealed they were using a Class III certificate for Class II products and skipping batch testing - saving approximately 35% in costs while claiming full certification.

What about suppliers who claim "our certificate is too new for the database"?

This is a common excuse, but it's false. All legitimate OEKO-TEX® certificates appear in the public database within 2-4 weeks of issuance at most. The testing institutes upload certificates regularly. If a supplier says their certificate is "processing" or "too new," ask for:

- The submission confirmation from the testing institute

- The testing report (issued before the certificate)

- The invoice from the testing institute

If they can't provide these within a reasonable timeframe, the certificate likely doesn't exist. We provide clients with submission confirmations the same day we apply for certification, and database links as soon as they're available.

How should you structure contracts and payments for verification?

Your commercial terms should support verification, not hinder it:

Contractual Protections:

- Certification Warranty Clause: "Supplier warrants that all products are OEKO-TEX® certified as specified, and that all certificates provided are authentic, current, and applicable."

- Right to Verify: "Buyer may conduct independent testing at Buyer's designated laboratory at any time."

- Consequences of Fraud: "If certification is falsified, Supplier bears all costs including recall, replacement, and damages."

- Indemnification: "Supplier indemnifies Buyer against all claims arising from certification issues."

Payment Terms Strategy:

- Never pay 100% upfront for certified goods

- Hold final payment (20-30%) until you receive and verify all documentation

- Consider letters of credit requiring presentation of valid certificates

- Progress payments tied to documentation milestones

Documentation Requirements:

Specify exactly what documents must be provided before payment:

- Valid OEKO-TEX® certificate (verified in database)

- Batch-specific test reports for the shipment

- Certificate of Conformity

- Material composition declarations

We include these requirements in our standard contracts because we can meet them. A supplier who resists is telling you they can't.

How does third-party inspection help?

For significant orders, consider third-party inspection services like SGS, Bureau Veritas, or Intertek for:

- Document verification: Checking certificates against databases

- Pre-shipment testing: Sampling from production for independent analysis

- Factory audits: Assessing actual implementation of systems

- Supply chain verification: Tracing materials back to sources

Costs typically range from 0.5-1.5% of order value - minimal compared to risk. More importantly, requiring these services deters fraudulent suppliers from engaging with you.

What about digital verification tools?

Several platforms now offer certificate verification services:

- OEKO-TEX® database: The official source

- Supply chain transparency platforms: Like TextileGenesis, Retraced

- Blockchain-based systems: For immutable verification

- API integrations: Direct database connections for automated checking

We offer API access to our verification system for enterprise clients. Their systems can automatically check our certificate status in real-time, creating an automated verification layer.

What makes Fumao Clothing's certificates reliably verifiable?

After dealing with certificate fraud from all sides, we've built systems that make verification effortless:

1. Complete Digital Transparency:

- Real-time database access: Certificates appear in OEKO-TEX database within 48 hours of issuance

- QR code traceability: Scan any fabric roll to access full documentation

- API integration: Direct connection to our verification systems

- Document portal: 24/7 access to all certificates and test reports

2. Verification-Friendly Documentation:

- Batch-specific reports: Every shipment has its own test documentation

- Cross-referenced systems: Certificates reference each other for full traceability

- Regular updates: New certificates issued annually without gaps

- Comprehensive scope: Certificates cover all components and processes

3. Open Verification Policy:

- Independent testing encouraged: We'll even recommend reputable labs

- Factory access: Virtual or physical tours anytime

- Technical access: Direct contact with compliance team

- Document sharing: Willing to share with your auditors, retailers, or regulators

4. Proactive Verification Support:

- Verification guides: We teach clients how to verify certificates

- Regular updates: Notifications when certificates renew or update

- Fraud detection help: We help clients spot fakes from other suppliers

- Industry collaboration: Working with OEKO-TEX to improve verification systems

A French luxury brand chose us specifically because of our verification transparency. Their compliance team said: "With Fumao, we spend 5 minutes verifying what takes 5 hours with other suppliers. The difference is systematic transparency versus selective disclosure."

How do we handle certificate renewals and updates?

Our renewal process ensures no verification gaps:

- 90-day notification: Clients alerted to upcoming renewal

- Parallel testing: New certificate testing overlaps old certificate validity

- Seamless transition: Database updated before old certificate expires

- Client notification: Automatic alerts with new certificate details

- Documentation update: All systems updated simultaneously

This eliminates the "certificate gap" that some suppliers use to sell uncertified goods while claiming certificates are "being renewed."

What's our track record on verification?

In 20+ years:

- Zero certificate authenticity challenges sustained

- 100% verification success rate when clients check our certificates

- 0% product recalls due to certification issues

- Thousands of successful verifications by clients, retailers, and regulators

We're so confident in our verification that we offer a Verification Guarantee: if any of our certificates fail to verify as described, we'll pay for independent verification and replace any affected goods at our cost. No legitimate factory needs to fear verification.

Conclusion

Verifying an OEKO-TEX® certificate's authenticity isn't just due diligence - it's brand protection, risk management, and ethical sourcing rolled into one forensic process. In an industry where certificate fraud is increasingly sophisticated, the difference between verified safety and marketing claims can determine whether your brand thrives or faces catastrophic failure.

The verification process I've outlined - from database checks to behavioral analysis to contractual protections - creates multiple layers of defense against increasingly sophisticated fraud. No single method is foolproof, but together they form a robust system that fraudulent suppliers cannot penetrate.

Remember: a truly certified manufacturer doesn't just provide a certificate; they provide verifiability, transparency, and operational evidence that stands up to the most rigorous scrutiny. They welcome verification because their systems are built for it, they understand it builds trust, and they know that in today's market, verifiable safety isn't a cost - it's a competitive advantage.

Ready to implement bulletproof certificate verification for your supply chain? At Fumao Clothing, we've built our reputation on transparency and verifiability. Contact our Verification Specialist, Elaine, at elaine@fumaoclothing.com for a comprehensive verification assessment of your current suppliers or to experience what truly verifiable certification looks like.

Certificate Verification Service: We offer brands a complimentary verification of up to three supplier certificates, including database checks, document forensics, and fraud risk assessment. This service has helped brands uncover over $2M in potential fraud in the past year alone.