As a fabric manufacturer who’s been through hundreds of OEKO-TEX® audits, I get this question all the time from brands. You see the label, you know it's a good thing, and you think: “Great, let's get all our fabrics certified to the highest level!” But here’s the reality check from the factory floor: OEKO-TEX® Product Class II is not a one-size-fits-all solution, and trying to apply it universally can waste your budget and even complicate your production. The system is designed with nuance—four different product classes that match real-world use. Using the wrong class is like using a racing bike for a mountain trail; it's the wrong tool for the job, even if the tool is excellent.

No, OEKO-TEX® Standard 100 Product Class II is not suitable for all types of clothing fabric. It is specifically designed for articles with direct skin contact, such as blouses, shirts, underwear, and bed linens. Using it for fabrics that don't touch the skin (like coat linings or decorative upholstery) is over-specification, while using it for babywear (which requires stricter Class I) is a critical under-specification and a compliance failure. The suitability depends entirely on the product's intended use, not just the fabric composition.

Understanding this classification is not bureaucratic box-ticking; it’s fundamental to smart sourcing. It protects your business from two major risks: 1) Paying a premium for unnecessary certification levels, and 2) Facing legal or reputational damage for under-certifying a sensitive product. Let’s cut through the confusion and look at the four classes, the science behind the limits, and how to match the right standard to every item in your line.

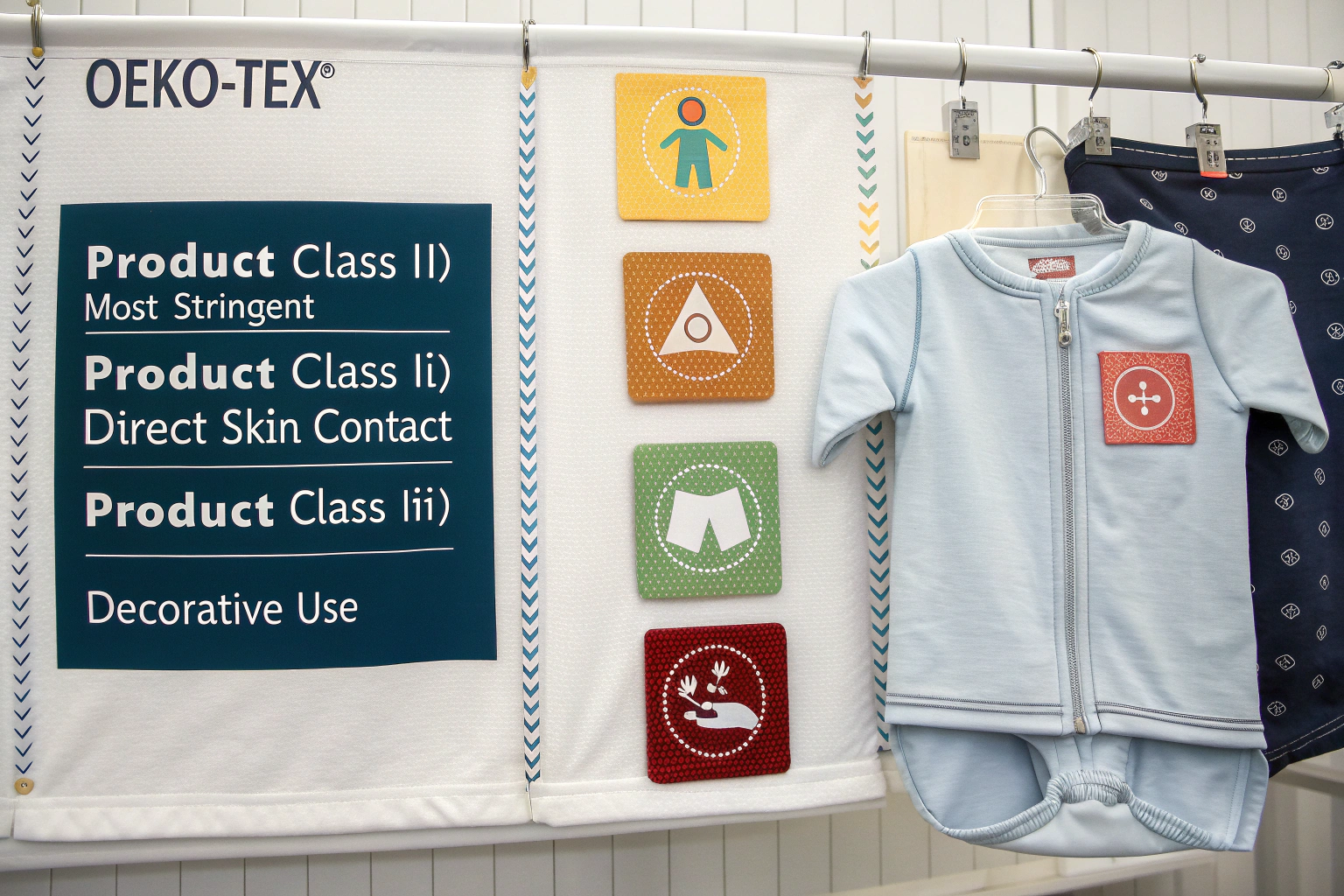

What Are the Four OEKO-TEX Product Classes and Their Limits?

The OEKO-TEX® Standard 100 system is built on a risk-based approach. The closer and longer a textile is to the human body—especially sensitive skin—the stricter the chemical limit values become. This is pure logic. The four classes are:

-

Product Class I: Articles for Babies and Toddlers (up to 36 months)

- Covers: All textile articles, toys, and bedding for infants.

- Key Logic: Babies' skin is thinner, their metabolism and immune systems are underdeveloped, and they often put textiles in their mouths. This class has the strictest limits, especially for substances like formaldehyde, heavy metals, and certain dyes.

- Fabric Example from Our Stock: Our GOTS-certified organic cotton interlock knit, specifically tested and certified for Product Class I for baby rompers and swaddles.

-

Product Class II: Articles with Direct Skin Contact

- Covers: Garments where a large part of the fabric touches the skin (underwear, t-shirts, shirts, socks, bed linen).

- Key Logic: This is the standard most brands think of. It assumes prolonged, direct contact with adult skin. Limits are stricter than Class III/IV but less strict than Class I.

- Fabric Example: Our BAMSILK (bamboo silk) satin and Tencel™ twills, widely certified in Class II for loungewear and dresses.

-

Product Class III: Articles without Direct Skin Contact

- Covers: Garments where only small parts touch the skin (jackets, coats, lining fabrics, padding).

- Key Logic: Because contact is limited, the permitted limits for certain substances are higher than for Class II. It’s a pragmatic, cost-effective standard for the right applications.

- Fabric Example: The polyester taffeta we produce for waterproof jacket linings or the quilted padding in winter coats.

-

Product Class IV: Decoration Materials

- Covers: Textiles used for decoration, such as curtains, tablecloths, wall coverings, and upholstery fabrics.

- Key Logic: Minimal skin contact, so it has the least restrictive limits of the four classes for many parameters.

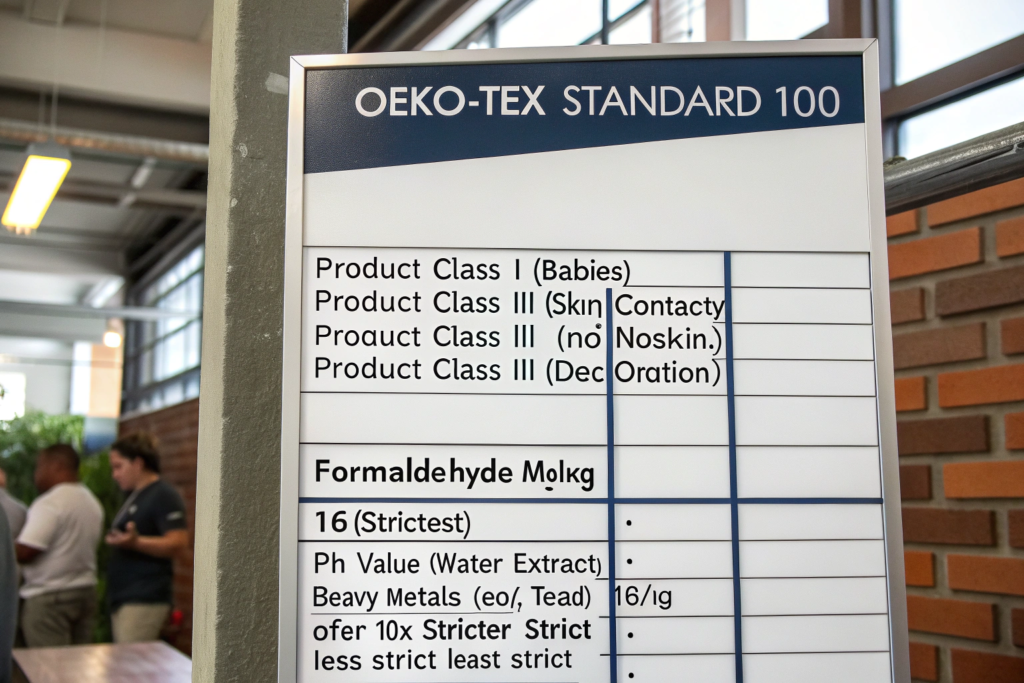

Here’s a quick comparison table showing the variation in limit values for a common parameter across classes (based on OEKO-TEX® STANDARD 100 criteria, as of my last audit):

| Substance / Parameter | Product Class I (Babies) | Product Class II (Skin Contact) | Product Class III (No Skin Contact) | Product Class IV (Decoration) |

|---|---|---|---|---|

| Formaldehyde [mg/kg] | 16 (strictest) | 75 | 300 | 300 |

| pH Value (water extract) | 4.0 - 7.5 | 4.0 - 7.5 | 4.0 - 9.0 | 4.0 - 9.0 |

| Heavy Metals (e.g., Lead) [mg/kg] | Often 10x stricter | Strict | Less Strict | Least Strict |

Why does the pH value range differ between classes?

This is a perfect example of the standard’s practical science. Human skin has a slightly acidic pH (around 5.5) as a protective barrier. For fabrics in Product Class I and II that have intense, direct contact, the pH must be nearly neutral to slightly acidic (4.0-7.5) to avoid disrupting the skin’s natural balance, which can cause irritation or dryness. For Product Class III and IV fabrics, where contact is minimal or brief, a wider, more alkaline range (up to 9.0) is permitted because the risk of skin disruption is low. This allows for more industrial finishing processes on, say, a coat’s outer shell fabric. Detailed technical bulletins on textile chemical safety and pH balance can provide deeper scientific context.

Can a single fabric be certified for multiple classes?

Yes, absolutely, and this is a key strategy for efficiency. At Shanghai Fumao, we often have a base fabric tested and certified for multiple product classes in a single application. For example, a 100% cotton poplin might be certified for Class II, III, and IV. This gives our clients maximum flexibility. They can use the same fabric for a shirt (Class II), a jacket lining (Class III), and maybe even a tote bag accessory (Class IV) without needing separate certificates. The testing cost is slightly higher upfront, but it saves significant time and money down the line. When sourcing, always ask your supplier: “For which product classes is this fabric certificate valid?”

When Should You Use Product Class II vs. Class III for Apparel?

This is the most common and costly area of confusion. The decision rule is simple: What is the garment’s primary function and contact area?

Use Product Class II when:

- The garment’s main purpose is to be worn against the skin. (e.g., a t-shirt, a dress, a pair of leggings).

- Even if it’s an outer layer, it’s designed for intimate, full-coverage wear. (e.g., a base layer for skiing, a silk slip dress).

- You are making bed linen or underwear.

Use Product Class III when:

- The garment is primarily an outer layer, and only parts like the collar, cuffs, or neckline have intermittent skin contact. (e.g., a wool blazer, a winter coat, a suit jacket).

- The fabric is used as an interlining, padding, or lining inside a garment.

- You are making hats, belts, or other accessories where skin contact is limited.

A real case from last autumn: A European brand was developing a wool-blend overcoat. They initially insisted on Class II for the entire coat, including the thick outer shell fabric. Our technical team advised that the outer shell only needed Class III, but the satin lining fabric (which touches the wearer’s arms and back) should indeed be Class II. By splitting the specification, they saved over 18% on certification costs for that fabric component without compromising safety or compliance. It’s this kind of practical sourcing intelligence that defines a strong partnership. Forums discussing cost-effective sustainable sourcing strategies often highlight such precision in specification.

What about blended fabrics or multi-component garments?

This is critical. The entire finished article is certified, not just the main fabric. If you have a Class III jacket with a Class II lining, metal zippers, plastic buttons, and printed labels, all components must be compliant for the final product to achieve its target class. The final certification is only as strong as its weakest link. This is why working with an integrated supplier like us is a huge advantage—we can source or advise on compliant trims from our network. A great resource for understanding this holistic approach is reading about managing compliance in complex garment assemblies.

Is there a scenario where Class II is used for an "outerwear" fabric?

Yes, but it’s about design intent, not just category name. Consider a lightweight linen overshirt designed to be worn directly on the skin as a summer cover-up. Even though it’s called “outerwear,” its use case is direct skin contact, so Class II is appropriate. The rule is: Certify for the use, not just the product category.

What Are the Risks of Using the Wrong Product Class?

The risks are financial, legal, and reputational. They flow in two directions: over-specification and under-specification.

Risks of Over-Specification (Using Class II for a Class III item):

- Unnecessary Cost: You pay for more stringent testing and potentially more expensive dyes/finishes without any added marketable benefit or safety need.

- Production Complications: The stricter chemical limits may restrict the finishes you can apply. For instance, achieving a certain durable water repellent (DWR) finish on an outdoor fabric might be harder under Class II limits, complicating your functional requirements.

Risks of Under-Specification (Using Class III for a Class II item):

- Legal & Compliance Failure: This is the severe risk. If you market a t-shirt as “skin-safe” but have certified it only to Class III, you are potentially non-compliant with consumer safety regulations in markets like the EU. You could face fines, recalls, or customs seizures.

- Brand Damage: If discovered—perhaps by a vigilant consumer or competitor—it can lead to accusations of greenwashing or negligence, destroying trust.

- Liability Exposure: If a customer has a skin reaction and your certification is for a lower class than the product’s use, your legal liability increases significantly.

How do testing institutes verify the intended product class?

When you apply for certification, you must declare the intended use of the article. The testing institute may ask for supporting evidence, like a product description, catalog image, or tech pack. They certify the article for that stated use. If you later change the use (e.g., sell a certified “lining fabric” as “babywear”), the certificate is invalid. Misrepresentation can lead to certificate revocation. It’s a system built on declared intent and professional integrity.

Can you upgrade a certificate from Class III to Class II later?

Not directly. If you have a fabric certified for Class III and later decide to use it for a Class II garment, you must submit a new application for the fabric (or the final garment) to be tested against the stricter Class II limits. This means new fees and a new testing timeline. This is why upfront planning is crucial. Industry guides on planning for textile compliance from the design stage stress this forward-thinking approach.

How Does Fumao Guide Clients in Selecting the Right Class?

We don’t just sell certified fabric; we act as a consulting partner in specification. Our process starts with a simple question: “What are you making, and who is wearing it?” From there, we map out a certification strategy across a client’s entire collection.

- Collection Audit: We review their tech packs and categorize each item by likely product class.

- Fabric Portfolio Matching: We show them our existing fabric stock pre-certified for the relevant classes, speeding up their process dramatically. (For instance, we have over 50 knitted fabrics pre-certified for Class I & II).

- Cost-Benefit Analysis: For custom developments, we provide a transparent breakdown of the testing cost and timeline implications for different class options.

- Trim Sourcing Support: We advise on or source compliant threads, labels, and trims to match the target class of the final garment.

For example, a startup making gender-neutral basics came to us with a simple line: t-shirts, sweatshirts, and canvas trousers. We recommended:

- T-shirts (100% cotton jersey): Use our stock fabric certified for Class II.

- Sweatshirts (cotton-poly fleece): The inner, brushed loop-back (touching skin) needed to be Class II. The outer face could be Class III. We provided a composite fabric certified accordingly.

- Canvas Trousers (heavy twill): Since it’s worn over underwear with limited direct skin contact on the legs, Class III was sufficient and cost-effective.

This tailored approach gave them credible safety messaging for their core product (the tee) while optimizing their overall budget. It’s this granular, practical guidance that sets a true partner apart. For brands navigating this alone, resources like the OEKO-TEX® Buying Guide are a necessary starting point, but expert interpretation is key.

What is the most common mistake you see brands make?

Hands down, it’s certifying the fabric but not the final garment. A brand will buy a beautiful Class II-certified linen from us, then send it to a factory that uses non-certified thread, non-certified dyes for label printing, or a non-certified softening wash. The final product is not OEKO-TEX® certified. We constantly educate our clients to either use certified garment makers or apply for certification of the final, assembled product with all its components. This is non-negotiable for claim integrity.

How do seasonal trends (like sheer fabrics or layering) affect classification?

Trends absolutely influence class decisions. The rise of sheer mesh fabrics is a perfect example. Even if worn as an overlay, a sheer mesh blouse has extensive direct skin contact. It must be Class II. The “layering” trend also complicates things. A thin, lightweight vest designed to be layered under everything is a Class II item, even if it’s called a “vest.” We always advise clients to think from the consumer’s wardrobe reality, not just the tech pack sketch.

Conclusion

OEKO-TEX® Product Class II is a powerful tool for building trust in your skin-contact apparel, but it is just one tool in a well-organized kit. Suitability is not about the fabric’s inherent quality, but about its destined use. The smartest brands—and the most responsible suppliers—understand this ecosystem of four classes. They use this knowledge to make precise, cost-effective, and legally sound decisions that protect their customers and their bottom line. It’s not about getting the “highest” certification; it’s about getting the right one.

Navigating this landscape requires a partner who sees the whole picture, from the chemistry of the dye bath to the final use of the garment. At Shanghai Fumao, we provide that clarity, ensuring every meter of fabric you source is not only beautiful and functional but also correctly and credibly certified for its purpose. Let’s build your collection on a foundation of precise intelligence, not guesswork. Contact our Business Director Elaine to specify your next project with confidence: elaine@fumaoclothing.com.