You've just landed a massive order: 50,000 meters of recycled polyester for a global sportswear chain. The tech packs are signed, the deposit is paid, and production is humming. Then, your client's compliance team sends an email that chills your blood: "Please provide valid Transaction Certificates (TCs) for the full order quantity to verify recycled content before shipment." If you can't produce them, the entire order—and the relationship—hangs in the balance. For large volume wholesale, this isn't a hypothetical scenario; it's a daily reality. Why has this single document become the non-negotiable gatekeeper for multi-million dollar deals?

A Transaction Certificate (TC) is the legal and financial linchpin for large wholesale orders because it provides the only independently verified, batch-specific proof that certified materials (like GOTS organic cotton, RCS recycled polyester, or FSC viscose) are authentic and traceable through the supply chain. For bulk orders, the stakes are exponentially higher: the financial risk of material fraud, the legal liability of false claims, and the reputational damage of a public greenwashing scandal are magnified. A TC transforms subjective trust into objective, auditable fact, making it indispensable for brands fulfilling stringent ESG (Environmental, Social, and Governance) mandates from investors and retailers.

In essence, a TC is the supply chain's immune system for large orders. It doesn't just mitigate risk—it systematically eradicates the ambiguity that can poison high-value, long-term partnerships. For wholesalers and manufacturers, it's no longer a "nice-to-have" sustainability accessory; it's a fundamental component of commercial due diligence and operational integrity. Without it, you are not just selling fabric; you are selling blind trust in a world that increasingly demands proof.

So, what specific large-order risks does a TC neutralize? How does it directly impact financial margins and supply chain resilience? And what practical steps ensure your TC process is as scalable as your production? Let's dive into the critical reasons why this document is the bedrock of modern, large-scale textile trade.

Risk Amplification: Why Volume Turns Small Issues into Catastrophes

In wholesale, volume doesn't just scale up quantity—it multiplies risk. A 5% quality defect on a 1,000-meter order is a manageable problem. The same 5% defect on 100,000 meters is a financial disaster and a logistical nightmare. This principle of risk amplification applies even more severely to material authenticity and compliance. A missing or fraudulent TC for a large order doesn't just affect a single shipment; it can unravel years of brand equity and trigger contractual penalties that dwarf the order's value.

The core risks amplified by volume are financial liability, regulatory non-compliance, and brand equity destruction. A large retailer or brand cannot risk a recall or a compliance fine that would make headlines. Their due diligence processes are therefore designed to catch any weakness before it enters their system. The TC is their primary screening tool. It provides a clear, third-party-audited paper trail that the materials they are purchasing on a massive scale are exactly what they claim to be.

Let's dissect how the TC acts as a critical defense against two specific, volume-driven threats.

How Does a TC Prevent Multi-Million Dollar Material Substitution Fraud?

The financial incentive for material substitution scales with order size. The cost difference between certified organic cotton and conventional cotton—or between virgin and recycled polyester—can represent hundreds of thousands of dollars in "savings" for an unscrupulous supplier on a large order. A TC makes this fraud virtually impossible to hide. The certification body's Chain of Custody (CoC) audit requires a mass balance: the amount of certified material sold (covered by outgoing TCs) must match the amount purchased (covered by incoming TCs), minus a small, documented processing loss. For a 50-ton order of GOTS cotton, any significant, unexplained shortage would be an immediate red flag. At Shanghai Fumao, our vertically integrated tracking means we can provide TCs that correspond precisely to the mass of certified yarn we input. This system, which we explain to clients as part of our transparent sourcing protocol for bulk sustainable textile orders, is what allowed a major European retailer to confidently place a 200,000-meter order for our organic linen last year, knowing their investment was protected.

Can a Missing TC Invalidate a Brand's Entire Sustainability Report?

For publicly traded companies or brands with published ESG goals, large-volume purchases form the backbone of their sustainability metrics (e.g., "30% of our 2024 collection used recycled materials"). A TC is the auditable evidence required to make these claims. Without a valid TC for a bulk order, that volume cannot be counted toward their goals, potentially putting them in breach of their own public commitments or investor covenants. This is a C-suite level risk. We've seen this firsthand with a global activewear brand that audits all bulk suppliers. They require TCs not just for final reconciliation, but as interim documentation during production. Our ability to provide sequential, batch-matched TCs throughout the production of their high-volume performance fabric runs is a key reason we are a Tier-2 supplier in their system. This isn't just about selling fabric; it's about enabling their corporate reporting integrity.

Financial & Operational Advantages in Bulk Procurement

While risk mitigation is the primary driver, viewing TCs solely as a defensive cost is a strategic mistake. For large orders, a valid TC system unlocks significant financial benefits and operational efficiencies that directly improve your bottom line and supply chain agility. It transforms compliance from a tax into an investment.

Firstly, TCs secure preferential financing and insurance rates. Banks and trade finance institutions increasingly offer lower interest rates or better terms for transactions backed by verifiable, sustainable supply chains, as they are deemed lower risk. Secondly, they streamline and speed up the buyer's internal approval and payment processes. A large brand's accounting department can release milestone payments faster when the required compliance documentation (the TC) is already attached to the shipment notice, reducing your cash conversion cycle.

The operational leverage gained is tangible, especially in two key areas.

How Do TCs Facilitate Faster Payment and Improved Cash Flow?

Large brands have rigid internal controls. Their payment release is often gated on the receipt of specific compliance documents. If you ship 100,000 meters of fabric but the TC is delayed by two weeks, their accounts payable team will withhold the final 30-50% payment until the document is received and verified. This strains your liquidity. By integrating TC generation into our production timeline—issuing it concurrently with the Bill of Lading—we enable our clients to submit all required paperwork to their finance team immediately. For a long-standing client in the US home textiles sector, this practice has consistently shaved 7-10 days off their payment cycle for our bulk jacquard orders. This reliability in aligning documentation with financial workflows for wholesale textile imports is a hidden competitive advantage that strengthens partnerships.

Do TCs Provide Leverage in Long-Term Contract Negotiations?

Absolutely. When you can reliably provide TCs for large volumes, you transition from being a commodity supplier to a strategic compliance partner. This gives you significant leverage in negotiating annual framework agreements, pricing stability clauses, and priority production slots. A brand knows that switching to an uncertified or unreliable supplier for a core material carries immense hidden costs and risks. We experienced this with a fast-fashion group based in Spain. Our consistent provision of RCS TCs for their bulk recycled polyester fleece orders over three seasons allowed us to negotiate a 12-month fixed-price contract, insulating both of us from market volatility. This stability, built on verifiable documentation, is invaluable for planning the financial planning benefits of long-term fabric supply contracts.

Scalability and Audit-Readiness for Enterprise Clients

Enterprise clients don't just buy products; they integrate suppliers into their global audit and reporting systems. Your ability to scale your TC management process to match their volume and complexity is a direct test of your operational maturity. For a 500,000-meter annual commitment, a supplier that struggles with manual TC requests for each 10,000-meter shipment becomes a bottleneck, not a partner.

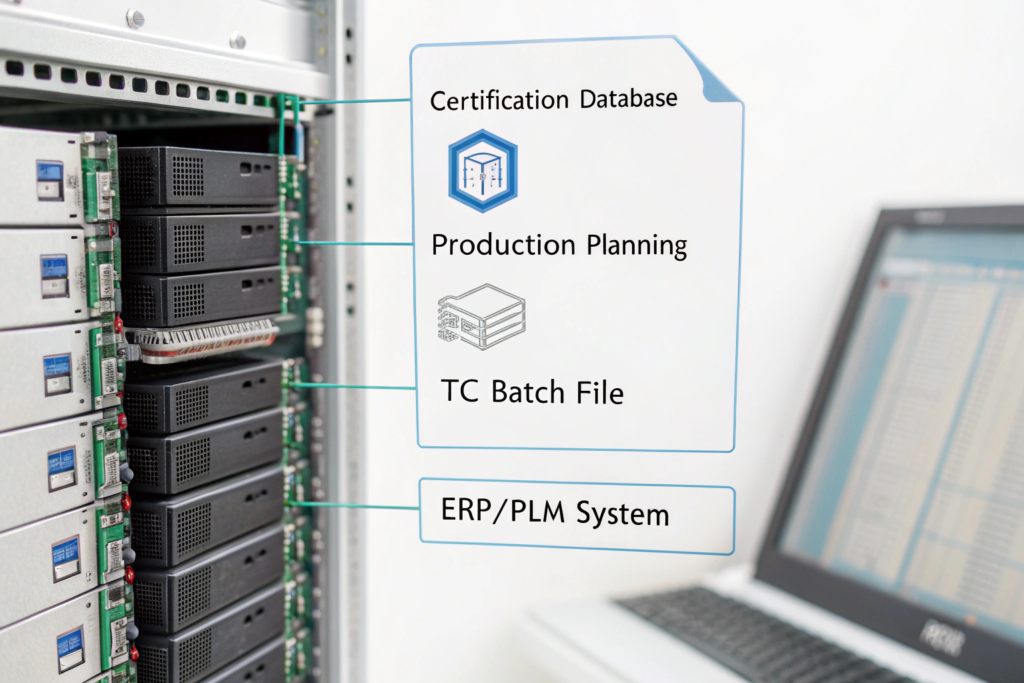

Scalable TC management means systematic, automated, and pre-emptive documentation. It requires digital record-keeping, integration between production planning and certification databases, and the ability to generate and transmit TCs in standardized digital formats (like PDF/A) that can be ingested into the client's Product Lifecycle Management (PLM) or ERP system. This level of integration is what separates order-takers from strategic vendors.

Building this capability is not optional for servicing large accounts. Let's examine the practical components.

What Does an Audit-Ready TC Archive Look Like?

An audit-ready archive is more than a folder of PDFs. It is a searchable, logically organized digital repository where every TC is linked to its corresponding sales order, production batch number, and shipping document. For each bulk order, there should be a master file containing the TC, the supplier's scope certificate, supporting test reports, and the mass balance calculation. When a client's auditor arrives (physically or virtually), you should be able to retrieve the complete dossier for any shipped order in under two minutes. At Shanghai Fumao, we've implemented a cloud-based system for our key accounts. When a major German brand conducted their annual sustainability audit last quarter, we provided a single, password-protected link with all TCs and supporting data for their past year's purchases, categorized by their internal material codes. This mirrored the best practices found in guides for preparing digital documentation for ethical trade audits, impressing their auditors and cementing our status.

How Can TC Data Integration Streamline Re-orders and Forecasting?

For ongoing bulk programs, historical TC data is a goldmine. It provides a verified record of material consumption rates, which helps both parties forecast future needs more accurately. For example, if a client's TCs show they consume an average of 15,000 meters of a specific GOTS cotton poplin per month, we can proactively reserve capacity and pre-book certified yarn. This moves the relationship from transactional to collaborative planning. We are currently piloting a system with a Scandinavian children's wear brand where their TC data (volume, issue date) automatically populates a shared forecasting dashboard. This level of integration, moving beyond basic ERP integration tips for apparel manufacturers and suppliers, reduces lead times by weeks and builds unparalleled supply chain resilience.

Conclusion

Ultimately, for large volume wholesale, the Transaction Certificate must be reframed from a compliance cost center into a core value driver. It is the tangible asset that enables premium pricing, protects against catastrophic risk, and builds the trust required for strategic partnerships. In a market where consumers and regulators are demanding radical transparency, the supplier that masters TC traceability holds the keys to the largest, most lucrative orders.

The brands placing these orders are not just buying fabric; they are buying insurance, credibility, and a share of your operational integrity. Your proficiency in providing TCs signals that you understand the rules of modern commerce and are equipped to be a long-term player on the global stage.

Ready to secure your large-volume orders with unshakable traceability and turn compliance into a competitive edge? Partner with a supplier for whom bulk TC management is a core competency, not an afterthought. At Shanghai Fumao, our investment in vertically integrated control and digital systems allows us to provide seamless, scalable, and audit-ready Transaction Certificates for orders of any size. We ensure your massive investment is protected from fiber to finish. Let's build a bulk sourcing strategy that is as robust as it is profitable. Contact our Business Director Elaine to discuss your large-scale needs: elaine@fumaoclothing.com.