You've just been notified that your apparel shipment is stuck at customs. The agent is asking for additional documentation—proof of origin, material composition, maybe even environmental compliance data. Days tick by, demurrage fees pile up, and your launch date slips away. This nightmare is becoming more common, especially for shipments heading to Europe and North America. Now, imagine an alternative: your shipment sails through the "green channel" with minimal delay. What's the difference? Increasingly, the answer lies in the factory's CMIA certification. It's not a magic wand, but it is a powerful system that transforms your shipment from a "high-risk, inspect me" candidate into a "low-risk, verifiable" one. As a supplier deep in the logistics chain, I've seen firsthand how a disciplined factory's documentation, driven by CMIA, can turn a customs bottleneck into a smooth process.

Think of customs clearance like airport security. Most passengers go through standard screening. But travelers with TSA PreCheck or Global Entry have already been pre-vetted—their information is in the system, they're known travelers, and they move through faster. A CMIA-certified factory essentially gives your shipment a form of "Commercial PreCheck." It doesn't guarantee no inspection, but it significantly lowers the probability because it provides customs authorities with what they increasingly want: transparent, organized, and verifiable data about how and what was manufactured. Let's break down exactly how this system cuts through red tape.

The Core Advantage: Organized, Auditable Documentation

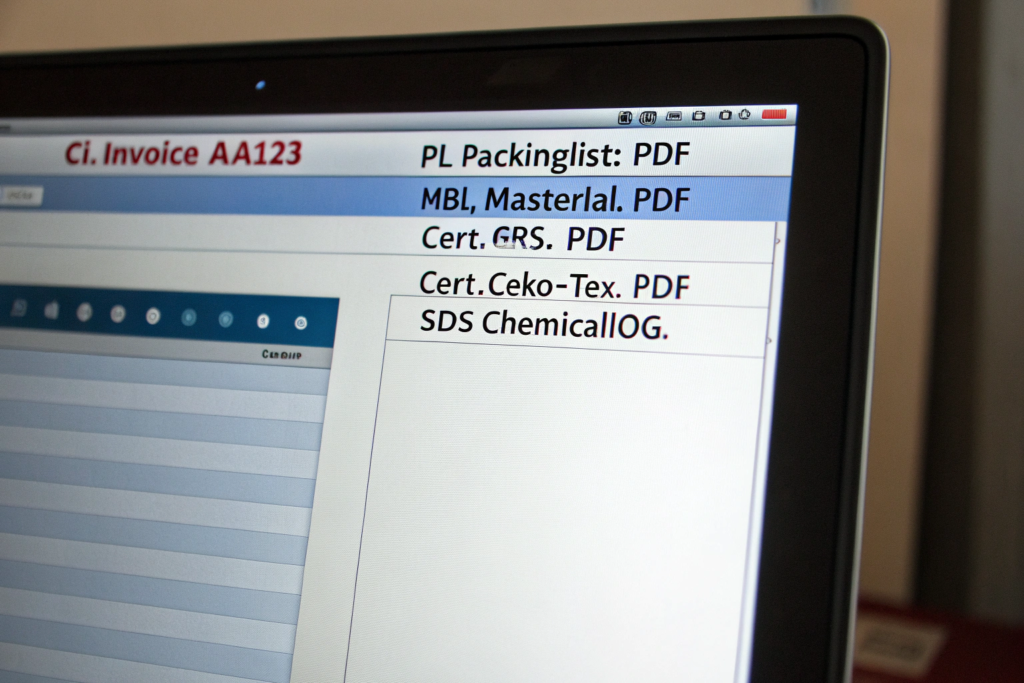

The single biggest reason CMIA-certified shipments clear customs faster is documentation integrity. Customs officials hate confusion. They love order. A CMIA-certified factory is, by definition, an organization that maintains meticulous, auditable records as part of its daily operation. When it's time to export, pulling together a customs dossier isn't a last-minute scramble—it's a routine output of their system.

What a CMIA System Guarantees (That Customs Values):

-

Accurate and Consistent Record-Keeping: The factory tracks material inputs (fabric, thread, trims) by batch and supplier. This means the commercial invoice and packing list can be cross-referenced with internal material logs. Discrepancies in weight or value—a major red flag for customs—are less likely.

-

Verified Material Information: For claims like "Made from Recycled Polyester" that affect duty rates or qualify for preferential treatment, customs may ask for proof. A CMIA factory sourcing GRS-certified recycled fabric from a partner like Shanghai Fumao will have the GRS Transaction Certificates filed and ready. This isn't an extra step; it's part of their controlled documentation.

-

Chemical Management Records: While not always requested upfront, having a well-maintained chemical inventory and Safety Data Sheet (SDS) library proves the factory is aware of and controls its inputs. If a question arises about restricted substances (e.g., under EU REACH), the factory can respond with evidence swiftly, preventing a hold for "suspected non-compliance."

The Real-World Impact:

An importer of children's knitwear into Germany shared that before switching to a CMIA-certified factory, their average customs clearance time in Hamburg was 4-7 days. After the switch, it dropped to 1-2 days. The German customs broker explained: "The documentation package from the new factory is complete. The material descriptions match the harmonized codes perfectly, and they even include test report references. It's clear they have their processes under control, so we flag fewer of their shipments for review."

How This Beats the "Standard" Factory Approach

A non-CMIA factory often assembles documents per shipment based on memory or templated forms. The person filling out the commercial invoice might not know the exact recycled content percentage or the precise origin of a component. This leads to vague descriptions ("polyester sweater") instead of precise ones ("95% GRS recycled polyester, 5% spandex sweater"). Vague descriptions invite scrutiny.

Your Actionable Step as the Importer

In your supplier agreement, stipulate that the pre-shipment document pack must include, at minimum: Commercial Invoice, Packing List, Bill of Lading, and a Material Certification Summary that lists key components and their certified origins (e.g., Fabric: GRS-certified Recycled Polyester, Mill Cert #XXX). A CMIA-certified factory will not see this as a burden.

Pre-Empting Modern Regulatory Checks: The Carbon and Compliance Data Advantage

Customs is evolving from just checking value and origin to enforcing environmental and social regulations. This is where CMIA certification shifts from a "nice-to-have" to a critical clearance accelerator.

1. The Carbon Data Mandate (Coming Soon for Real):

The EU's Carbon Border Adjustment Mechanism (CBAM) is the game-changer. While initially for heavy industries, its expansion to textiles is widely anticipated. Under CBAM, importers will need to declare the embedded carbon emissions of their goods. A non-CMIA factory will have no idea. A CMIA-certified factory is already measuring its carbon footprint (Scope 1 & 2 emissions) as part of its management system.

- For Customs: You can submit a verified carbon footprint report per dozen garments or per kilogram of product. This data, coming from an audited system, has high credibility, speeding up the declaration process and ensuring you pay the correct (and minimized) carbon tax.

- For You: You avoid using high "default values" assigned by customs to data-poor shipments, which would inflate your tax bill.

2. Responding to Due Diligence Inquiries:

Laws like the German Supply Chain Act (LkSG) and the proposed EU Corporate Sustainability Due Diligence Directive (CSDDD) require importers to prove they've checked their supply chains for environmental and social risks. If customs or a regulatory body asks you for evidence of environmental due diligence on a shipment, pointing to your factory's CMIA certificate and its performance data is a powerful, immediate response. It shows proactive management, not ignorance.

3. Managing "Green Claims" Scrutiny:

Customs in some markets are starting to check the validity of "eco-friendly" labels. A "recycled" claim without proof can lead to fines for false advertising. The CMIA factory's integrated documentation provides the proof at the point of import, preventing delays for verification.

Building the "Smart" Shipment File

The future-proof shipment will have a digital twin—a data packet that includes:

- Traditional Commercial Docs

- Material Certificates (GRS, GOTS, etc.)

- Carbon Footprint Data Sheet (from CMIA system)

- Factory Social Compliance Audit Summary

This comprehensive file answers questions before they are asked, which is the very definition of streamlined clearance.

How to Get This Data

Specify in your PO: "Factory to provide a Carbon Data Summary for this order based on your CMIA metrics." A serious partner will have this template ready.

Reducing Physical Inspection Risk Through Process Control

Customs uses algorithms and risk assessment to select shipments for physical inspection. What triggers a "high-risk" flag? Inconsistent paperwork, errors, and shipments from "less reliable" origins. A CMIA-certified factory's systemic approach lowers these risks at the source.

1. Consistency in Packaging and Labeling:

A core part of process control is standardization. This often extends to how cartons are packed, weighed, and labeled. Uniform, accurate carton weights and clear markings match perfectly with the packing list, reducing the "discrepancy" flags that trigger inspections.

2. Proven Supply Chain Traceability:

If the factory's system can trace a garment back to its fabric roll (a CMIA-encouraged practice for managing material aspects), it implies a high level of control over the entire production. Customs authorities view controlled, traceable supply chains as lower risk for issues like smuggling, mislabeling, or counterfeit goods.

3. Reputation as a "Known Exporter":

Over time, consistent, accurate documentation from a specific factory (identified by its Exporter ID) builds a positive profile with customs brokers and authorities. They learn that shipments from "XYZ Garments Co. (CMIA Certified)" tend to be clean. This intangible reputation is invaluable.

A Cautionary Tale vs. A Success Story:

- Factory A (Non-CMIA): Frequently had minor errors in invoices (typos in HS codes, fluctuating weights). Their shipments were inspected 30% of the time, causing chronic delays.

- Factory B (CMIA-Certified): Used standardized software to generate export documents directly from their production data. Their inspection rate was under 5%. Their broker cited "flawless paperwork" as the reason.

The Role of Technology Integration

Many advanced CMIA-certified factories use ERP or specific software that integrates production planning with export documentation. When the last carton is sealed, the system auto-generates accurate shipping documents. This eliminates human transposition errors—a major source of customs holds.

Conclusion

CMIA certification streamlines customs clearance not by changing the rules, but by ensuring your apparel shipment is the best-prepared, most verifiable, and least suspicious candidate in the queue. It transforms the factory from a document reactor into a document generator, with data flowing from an audited management system.

The benefits are tangible: fewer delays, lower demurrage risk, reduced chance of fines, and smoother cash flow. In an era where customs is becoming a gatekeeper for both trade and sustainability compliance, having a CMIA-certified manufacturing partner is no longer just about "being green." It's about being smart, fast, and reliable in getting your products to market.

Investing in such a partner might have a slightly higher FOB cost, but when measured against the hidden costs of customs delays—storage, missed sales, expedited freight—the ROI on streamlined logistics alone can be significant. If you're tired of supply chain surprises at the border, start by demanding more than just a sample from your factory. Demand a system. To connect with manufacturing partners who prioritize this level of operational excellence and transparency, contact us at Shanghai Fumao. Reach our Business Director, Elaine, at elaine@fumaoclothing.com. Let's build supply chains that flow as smoothly as they are sustainable.