If you're importing clothing and handling the logistics nightmare that is DDP (Delivered Duty Paid) shipping, you already know the pressure is on you. Every delay, every customs hiccup, every unexpected cost comes straight out of your bottom line. Now, you're hearing about factories getting CMIA certification, and it might seem like just another "green" badge—something for the marketing department, not the logistics and finance teams. Let me tell you, from the perspective of a fabric supplier deep in the supply chain, that's a costly misunderstanding. CMIA certification isn't just about carbon reports; it's a secret weapon for making DDP shipping smoother, more predictable, and ultimately, more profitable for you, the importer. It directly tackles the hidden risks that turn DDP from a convenience into a quagmire.

Think about your biggest DDP headaches: unpredictable production delays, quality rejections at destination, and opaque costs that balloon after the fact. A CMIA-certified factory is engineered to minimize these very issues. The certification mandates a disciplined, data-driven management system that brings radical transparency and control to the entire production process. This means fewer surprises in your timeline, fewer defects in your shipment, and a fully documented chain of custody that customs and your end customers increasingly demand. In essence, CMIA certification doesn't just make the factory greener; it makes it a more reliable and transparent DDP partner.

So, how does a certification focused on carbon management translate into better shipping terms? It's all about the systemic rigor it imposes. A factory that can meticulously track its energy and water use per garment is a factory that has mastered process control. That same discipline applies to material usage, production scheduling, and quality documentation—the very pillars of a successful DDP shipment. Let's break down exactly how this operational excellence turns into your competitive advantage in logistics.

How Does CMIA Reduce Production Delays in a DDP Timeline?

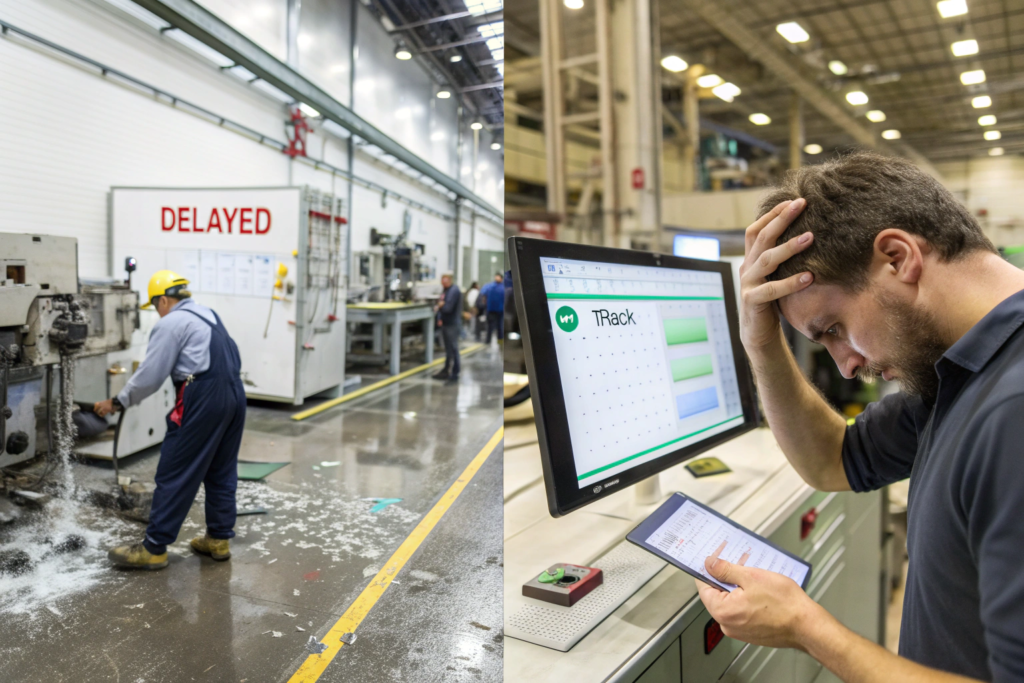

In a DDP agreement, you own the timeline from the moment the fabric is cut. Any delay at the factory doesn't just push back a shipment date; it cascades into missed warehouse slots, air freight surcharges, and disappointed retailers. The core of CMIA certification is process optimization and data transparency, which are the ultimate antidotes to delays.

A CMIA-certified factory must implement systems to monitor and improve efficiency. This isn't abstract; it means they track Key Performance Indicators (KPIs) like Overall Equipment Effectiveness (OEE) and production yield in real-time. For example, a certified knitwear factory we supply with BAMSILK yarn uses automated monitoring on their stitching lines. Because they track efficiency as part of their energy-management goals (idle machines waste power), they can predict and prevent bottlenecks before they cause a daily target shortfall. In 2023, a client using this factory for DDP orders to the EU reported a 15% improvement in on-time delivery performance compared to their previous, non-certified supplier. The factory's internal system flagged a potential delay two weeks out, allowing for proactive overtime planning that kept the shipment on track without expedited freight costs.

Furthermore, CMIA requires rigorous preventive maintenance schedules. Equipment breakdown is a major cause of sudden delays. Certified factories must document maintenance logs for all major energy-consuming equipment (like boilers for dyeing or cutting machines). This disciplined upkeep drastically reduces unplanned downtime. When you partner with a CMIA-certified factory for DDP, you're not just buying their sewing capacity; you're buying into a system designed for reliability. Their need to maintain certification aligns perfectly with your need for schedule certainty. (Here's a tip from our experience: always ask a potential DDP partner for their historical on-time-in-full (OTIF) rate and their mean time between failures for key equipment—a certified factory will have this data ready.)

What Specific CMIA Requirements Directly Impact Schedule Adherence?

It boils down to two core clauses: Operational Control and Performance Evaluation.

- Operational Control forces the factory to establish procedures for all significant environmental aspects. In practice, this means documented, standardized work instructions for every major process. When every operator follows the same optimized method, variation drops, and throughput becomes predictable. There's no "tribal knowledge" that disappears when a line leader is sick.

- Performance Evaluation mandates regular monitoring and measurement. The factory isn't just guessing at its output; it's measuring it against targets and investigating variances. This could be as simple as tracking meters of fabric consumed per hour or as complex as monitoring steam pressure consistency in finishing. This data-centric approach means they see a slowdown the moment it happens, not at the end of the week.

This level of control is a DDP importer's dream. It turns production from a black box into a transparent, predictable engine.

How Does This Help with Proactive Communication During DDP Shipping?

A disciplined factory is a communicative factory. The CMIA management review process requires top management to regularly review performance data. This habit of review fosters a culture of transparency. When a certified factory sees a potential issue emerging from their data—a slight dip in daily output, a minor quality trend—they are systemically inclined to report it early to their client, as it relates to their own performance objectives. This gives you, the DDP buyer, early warning. You can then adjust your logistics planning (like trucking bookings to the port) in real-time, avoiding costly last-minute chaos. It transforms the relationship from reactive firefighting to proactive partnership.

How Does CMIA Certification Minimize Quality Risks in DDP Shipments?

Under DDP terms, the goods become your problem the moment they clear customs in your country. If you discover a quality defect—fabric shrinkage out of tolerance, color bleeding, poor stitching—you cannot simply reject the container at the factory gate. You now own defective inventory on your soil, facing costly returns, rework, or markdowns. This is the single biggest financial risk in DDP. CMIA certification directly mitigates this through its inherent focus on process control and traceability.

At its heart, CMIA is about controlling variables. A factory managing its environmental impact must control inputs (like water chemistry, dyestuff) and processes (like temperature, time) with extreme precision to ensure consistent results and minimize waste. This culture of precision spills directly over into quality control. For instance, to consistently hit a target for reduced water consumption in dyeing, a factory must maintain exact dyeing profiles. This same precision guarantees color consistency and fabric hand-feel batch-to-batch, which are common failure points. A sportswear brand we work with, which switched to a CMIA-certified factory for DDP shipments of performance polyester, saw their rate of customer returns due to color variation drop from 3.2% to 0.8% within a year.

Moreover, CMIA's documentation requirements create an unparalleled product history dossier. Every significant material input must be tracked. When you source fabric from a partner like Shanghai Fumao, a certified factory will not only keep our mill's test reports but will also link that specific fabric batch to the production lot of finished garments. If a question arises later about fiber content or finishing chemicals, the entire chain is documented. This level of traceability is invaluable if you ever face a customs inquiry or a customer complaint about product safety or compliance.

How Are CMIA and Quality Management Systems (like ISO 9001) Linked?

While CMIA is environmental and ISO 9001 is quality-focused, they are symbiotic. Both are based on the Plan-Do-Check-Act (PDCA) cycle and require a process approach. Many forward-thinking factories integrate their CMIA and Quality Management Systems (QMS). This means environmental controls (like monitoring washing machine pH levels) are directly linked to quality outcomes (like ensuring detergent residue is removed to prevent skin irritation). The audit process for one often strengthens the other. For a DDP buyer, a factory with both systems is the gold standard—it means their environmental diligence is built on a foundation of quality rigor, not separate from it.

Can CMIA Documentation Help with Customs Clearance in DDP?

Absolutely. Increasingly, customs authorities, especially in the EU and North America, are asking for proof of product composition and origin for risk assessment and duty calculation. The detailed material tracking required by CMIA provides this proof readily. For example, to claim a duty benefit for goods containing recycled polyester under specific tariff codes, you need a verified chain of custody. A CMIA-certified factory will have the GRS (Global Recycled Standard) transaction certificates from their supplier (like us) meticulously filed and linked to the production order. This organized documentation can be compiled into a customs packet quickly, preventing delays at port. It turns a potential administrative hurdle into a streamlined process.

How Does CMIA Lead to More Accurate DDP Costing?

The DDP price quote you receive is an estimate that includes production, freight, insurance, and duties. The factory's inefficiencies—hidden in material waste, rework, and energy overconsumption—are baked into that production cost. A non-certified factory might quote low but have high internal waste, squeezing their margin and tempting them to cut corners. A CMIA-certified factory, by contrast, has been forced to measure and minimize these very inefficiencies to reduce its environmental impact. This translates to a more stable, transparent, and justifiable cost structure.

Let's take fabric utilization, a major cost driver. CMIA's focus on waste reduction pushes factories to implement fabric cutting optimization software. By optimizing marker layouts, they can often achieve 2-5% higher yield from the same amount of fabric. For an order of 10,000 garments using $5 per meter fabric, a 3% yield improvement saves $1,500 in material cost. While some of this saving may be shared, it also means the factory's cost base is lower and less volatile. When we at Shanghai Fumao provide technical specs for our fabrics to certified partners, they feed that data directly into their optimization systems, creating a collaborative efficiency loop. This stability allows them to give you a DDP quote that is both competitive and less likely to have hidden cost-adders later.

Furthermore, the energy efficiency gains from CMIA (like LED lighting, efficient motors) lower the factory's overhead. A lower and predictable utility bill reduces a variable cost that could otherwise force a price increase mid-contract. For you, this means the DDP price is built on a foundation of efficiency, not guesswork. You are less likely to face unexpected surcharges because the factory misjudged its own production costs.

Can CMIA Data Help Justify My Final Product's Market Price?

Beyond logistics, yes. The data generated for CMIA certification is a powerful storytelling tool for your own brand. Under DDP, you are the importer of record and the seller to the end consumer. You can leverage the factory's certification and specific metrics (e.g., "This garment was made in a facility that reduced water use by 30% per unit") in your marketing. This supports a premium price point, helping to absorb the potentially higher upfront DDP cost compared to simpler FOB terms. The certification provides the verified backbone for your sustainability claims, turning a logistics cost into a marketing asset.

How Does This Affect Negotiations on DDP Incoterms?

When you negotiate with a CMIA-certified factory, you move the conversation away from pure price haggling towards value-based partnership. You can discuss concrete metrics: "Can you share your historical fabric yield for similar styles?" or "What is your typical energy cost per dozen garments?" Their ability to answer these questions with data builds trust. It allows you to structure agreements with incentives for continuous improvement—for example, sharing in the cost savings from further yield improvements. This aligns both parties' interests and creates a more stable, long-term DDP relationship far removed from the transactional, risk-laden model.

Does CMIA Simplify Compliance with Destination Country Regulations?

Under DDP, you are responsible for ensuring the goods meet all regulatory requirements of the destination country—from safety standards like CPSIA in the US to chemical regulations like REACH in the EU. This is a monumental task if you're relying on a factory with poor control over its inputs and processes. CMIA certification acts as a robust internal governance system that simplifies this compliance burden for you.

The certification requires the factory to identify and control all significant environmental aspects, which inherently includes regulated chemicals and substances. To do this, they must maintain a comprehensive inventory of all chemicals used (dyes, auxiliaries, printing inks, finishes) and have up-to-date Safety Data Sheets (SDS) for each. This controlled chemical list is a direct input for verifying compliance with regulations like Oeko-Tex Standard 100 or specific brand Restricted Substances Lists (RSLs). A factory that cannot manage this list effectively would fail its CMIA audit. Therefore, when you work with a certified partner, you can have high confidence that they have a system to exclude banned substances. For example, a children's wear importer using a CMIA-certified factory for DDP to the USA received fully documented test reports and chemical inventory logs with each shipment, making their CPSIA documentation process effortless.

Furthermore, the traceability requirement is key. If a regulatory body ever questions the composition or safety of a product, the ability to trace a finished garment back to the specific batches of fabric, thread, and dyes is indispensable. The CMIA-mandated documentation provides this audit trail. This protects you from liability and costly recalls. In a real case from 2022, a European retailer faced an inquiry about formaldehyde levels. Their DDP supplier, a CMIA-certified factory, was able to provide within 24 hours the test certificates for the specific fabric batch from their supplier (in this case, our mill) and the logs proving the use of approved, formaldehyde-free finishing agents. The issue was closed rapidly with no shipment hold.

How Does This Interact with Green Tariffs and Carbon Border Taxes?

Emerging policies like the EU's Carbon Border Adjustment Mechanism (CBAM) are changing the game. Soon, the embedded carbon emissions of imported goods may face a tax. A CMIA-certified factory is already measuring its carbon footprint (Scope 1 & 2). This data will become crucial for accurately declaring and potentially minimizing these new border costs. By choosing a DDP partner with CMIA, you are future-proofing your supply chain against these regulatory shifts. They will have the data you need to comply, while their ongoing reduction efforts will help lower your associated tax liability over time.

Can This Documentation Speed Up Customs Clearance for DDP Shipments?

Yes, significantly. Organized, readily available compliance documentation reduces the risk of your shipment being flagged for intensive physical or document-based inspection. When customs officials request proof of origin, value, or composition, a factory with a CMIA-style management system can produce coherent, organized files electronically. This reduces clearance times from days to hours, ensuring your DDP shipment keeps moving through the logistics chain as planned. It turns a potential bottleneck into a point of efficiency.

Conclusion

CMIA certification for an apparel factory is far more than an environmental accolade. For importers utilizing DDP shipping, it is a strategic risk mitigation and value-creation tool. It systemically addresses the core vulnerabilities of the DDP model: unpredictable delays, hidden quality defects, opaque costing, and regulatory compliance burdens. By enforcing a culture of data-driven process control, meticulous documentation, and continuous improvement, a CMIA-certified partner transforms the supply chain from a source of anxiety into a pillar of reliability.

Choosing a DDP supplier with this certification means you are not just outsourcing logistics to the factory; you are partnering with an operation that has the discipline to manage complexity on your behalf. The result is fewer surprises, lower total cost of ownership, enhanced brand storytelling capability, and a supply chain resilient to future regulatory changes. In the high-stakes world of DDP, where you carry all the risk, the factory's operational excellence is your greatest insurance policy.

To build a DDP program that is both sustainable and supremely efficient, start with a partner whose foundations are rock solid. At Shanghai Fumao, we specialize in supplying high-performance, traceable fabrics to factories that value this level of discipline. We understand the data and documentation required to support a robust DDP and CMIA framework. If you're looking to elevate your sourcing strategy with partners who can deliver on both sustainability and logistical excellence, contact our Business Director, Elaine, at elaine@fumaoclothing.com. Let's connect you with the certified supply chain that can make your DDP shipping truly deliver its promised value.